Splicing device and method for large-size paper honeycomb parts

A splicing device, paper honeycomb technology, applied in the direction of layered products, etc., can solve the problems of honeycomb slippage, splicing out of tolerance, large part size, etc., to achieve the effect of ensuring smoothness, high pass rate preparation, and convenient splicing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

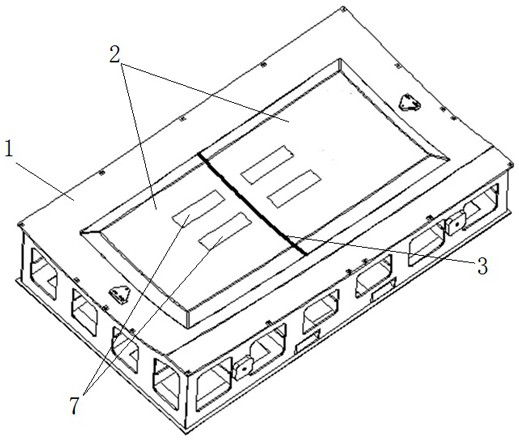

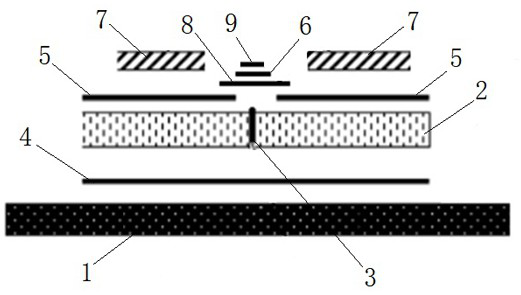

[0026] This embodiment is a splicing device and method for large-size paper honeycomb parts, the splicing device for large-size paper honeycomb parts, such as figure 1 with figure 2 As shown, the splicing molding tool 1 is included, and the honeycomb sandwich 2 to be spliced is encapsulated on the splicing molding tool 1; the splicing seam 3 places between the honeycomb sandwich 2 to be spliced is paved with foam glue; the honeycomb sandwich 2 and The first isolation layer 4 is laid between the splicing molding tooling 1, and the second isolation layer 5 is respectively laid on the top of the honeycomb interlayer 2; several pressing plates 7 are placed on the top of the second isolation layer 5; a peelable cloth is laid on the top of the splicing seam 3 8. A third isolation layer 6 is laid on the peelable cloth 8, and a gasket 9 is placed on the third isolation layer 6. Use the pressure plate to fix the honeycomb on both sides of the foam rubber without slipping, reduce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com