Hybrid drive punching machine

A hybrid drive, punching machine technology, applied in punching machines, presses, manufacturing tools, etc., can solve problems such as equipment operation or maintenance difficulties, unadjustable hydraulic telescopic cylinder strokes, etc., to achieve convenient operation or maintenance, good rigidity, and movement. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

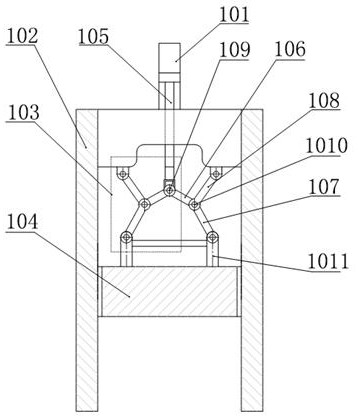

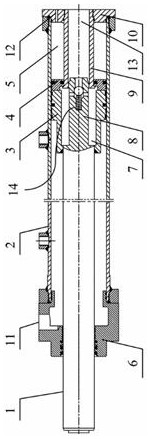

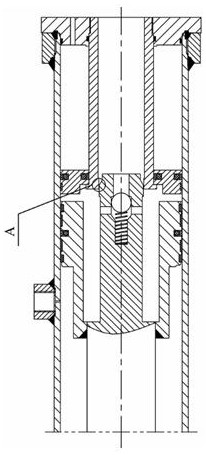

[0022] Such as Figure 1-4 As shown, a hybrid drive stamping machine includes a hydraulic telescopic cylinder 101, a frame 102 and a linkage mechanism, a piston rod 105 is installed in the hydraulic telescopic cylinder 101, a slide block 104 is housed in the frame 102, and the The connecting rod mechanism is formed by connecting two sets of toggle mechanisms 103 symmetrically. The toggle mechanism 103 includes a thrust rod 106, a connecting rod 107 and a secondary connecting rod 108. The piston rod 105 is hinged to the thrust rod 106 through a round pin 109. The end of thrust rod 106 is connected with connecting rod 107 and auxiliary connecting rod 108 by round pin 10, and the other end of described auxiliary connecting rod 108 is fixed on the frame 102, and described connecting rod 107 is connected with slide block 104, and in An adjustment screw 1011 perpendicular to the slider 104 is installed between the connecting rod 107 and the slider 104 , and the two adjustment screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com