Maintainable methylsulfonylbenzene synthesis device

A methylsulfonyl benzene and synthesis device technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the inconvenient waste discharge, inability to control the temperature of liquid addition, inconvenient slag collection and Mixing effect and other problems, to achieve the effect of convenient cleaning and increasing the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

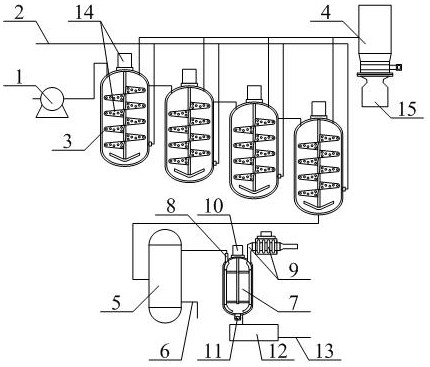

[0038] as attached figure 1 And attached image 3 shown

[0039]The present invention provides a maintainable methylsulfonylbenzene synthesis device, which includes a transfer pump 1, a methyl chloride conduit 2, a methylation kettle 3, a regenerative incinerator 4, a split tower 5, a brine conduit 6, and a washing tower 7 , feed pipe 8, controllable water inlet frame structure 9, rotating cleaning frame structure 10, discharge valve 11, centrifuge 12, methylsulfonyl benzene conduit 13, mixing and stirring device 14 and waste material collecting frame structure 15, described Delivery pump 1 is connected through the upper left side of pipeline methylation kettle 3; described methyl chloride conduit 2 is connected with the lower right side of methylation kettle 3 respectively; described methylation kettle 3 is provided with four, The methylation kettle 3 is arranged downwards from left to right; the regenerative incinerator 4 is respectively connected to the upper right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com