Double-sided liquid feeding device

A double-sided, fabric technology, used in textiles and papermaking, papermaking machines, fiber raw material processing, etc., can solve the problems of difficult to guarantee product quality, heavy water guide rollers, low production efficiency, etc., and achieve flexible and adjustable sizing action. , The equipment design is simple and reasonable, and the production efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

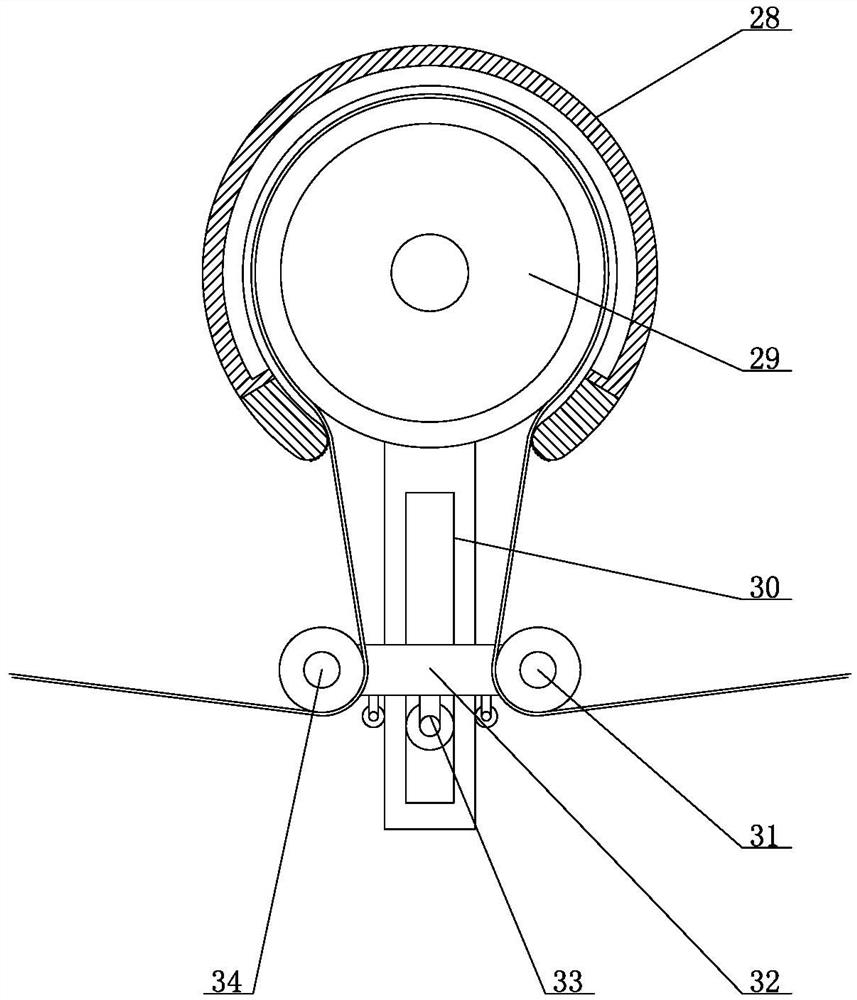

[0045] In this example, if image 3 As shown, a paper surface polishing functional group is set at the paper output end of the Zhashui device, and the paper surface polishing functional group includes a polishing sleeve with a cross-section of "Ω" shape, and a polishing guide is set in the polishing sleeve. Roller, on the inner wall and the outer wall of the polishing sleeve, the polishing surface is set; the polishing lifting slide rail is set under the polishing guide roller, and the electric polishing mobile pulley is set in the polishing lifting slide rail. A polishing pole is horizontally installed on the moving block, and a left polishing guide roller and a right polishing guide roller are respectively installed at both ends of the polishing pole; the length of the polishing pole is adjustable, and then the left polishing guide roller The distance between the polishing guide rollers can also be adjusted; after the paper that has passed through the zha water passes under ...

Embodiment 3

[0049] In this embodiment, one end of the Zhashui upper guide roller of the Zhashui device is connected to the Zhashui drive motor, and the other end of the Zhashui upper guide roller is installed with an anti-twisting stop device.

[0050] Such as Figure 4 with 5As shown, the anti-twisting and stopping device includes an upper brake cylinder and a lower brake cylinder. The telescopic shafts of the upper brake cylinder and the lower brake cylinder are all set relative to the upper guide rollers on the water. The arc-shaped upper brake pad and the lower brake pad are respectively fixed on the shaft; when the emergency stop is stopped, the upper brake cylinder and the lower brake cylinder are started while the Zhashui drive motor is stopped, so that the upper brake pad and the lower brake pad are in contact with the Zhashui upper guide roller. The upper surface and the lower surface of the end of the roller are in contact, so that the two ends of the Zhashui upper guide roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com