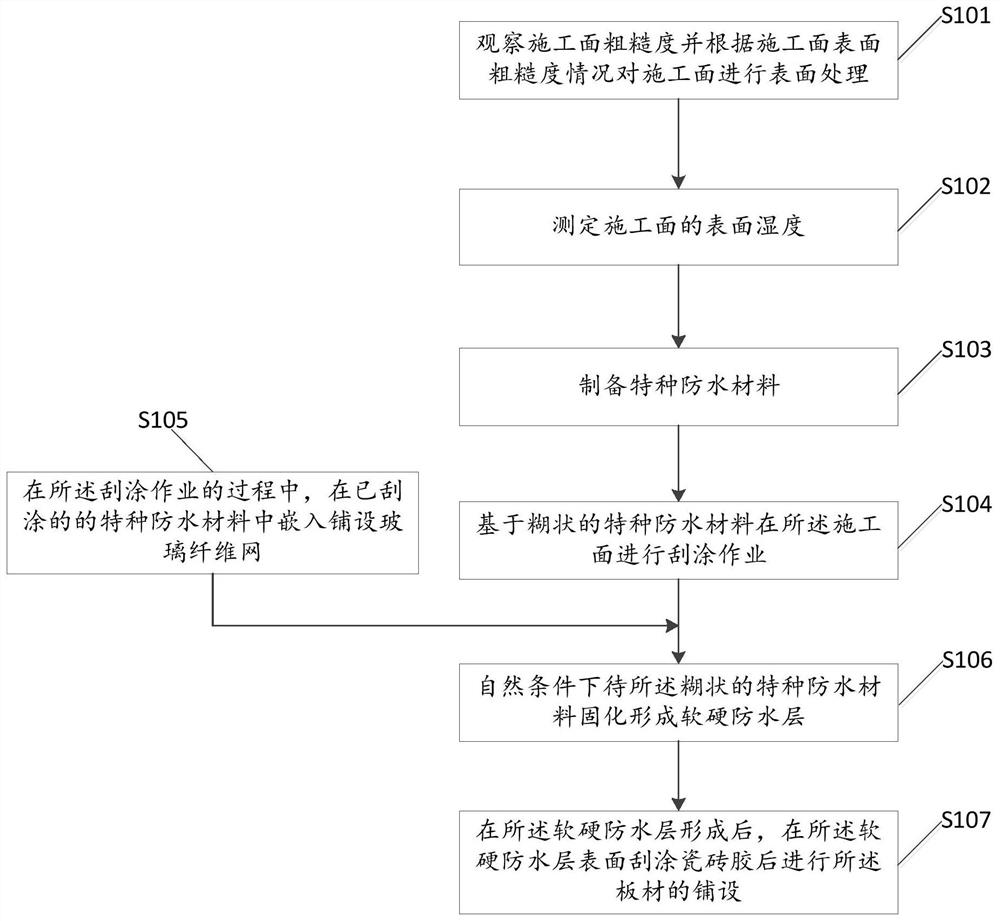

Special waterproof material construction method and system

A technology of waterproof materials and construction methods, applied in building insulation materials, building components, etc., can solve problems such as long construction period, increased construction cost, and waterproof failure, and achieve the effect of high operating efficiency, low operating requirements, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] Specifically, after the special waterproof material passes through at least 40% of the final setting time of the tile adhesive, the tile adhesive is scraped on the surface of the special waterproof material that has been scraped and then the board is laid;

[0050] After measurement (making a batch of test pieces at the same time, and cutting the test pieces one by one according to a certain time interval, observing their cross-sectional composition), it is found that the final setting process of the special waterproof material passes through at least 40% of the external special waterproof material. After the final setting time of the tile adhesive, the special waterproof material about 1.4 mm away from the surface of the soft and hard waterproof layer is close to the final setting state (the strength test has a preset strength level of more than 88%, and almost no deformation occurs), Its surface can continue to be further processed, such as bonding the board after scra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com