Air flow control device, fan blade comprising same and wind generating set

A control device and air flow technology, applied in the fields of wind turbine blades, air flow control devices, and wind turbines, can solve the problems of boundary layer flow separation of wind power blades, improve anti-separation ability, strengthen energy mixing, and increase internal energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In the following, the present invention will be more clearly and completely described by means of an embodiment in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the embodiment.

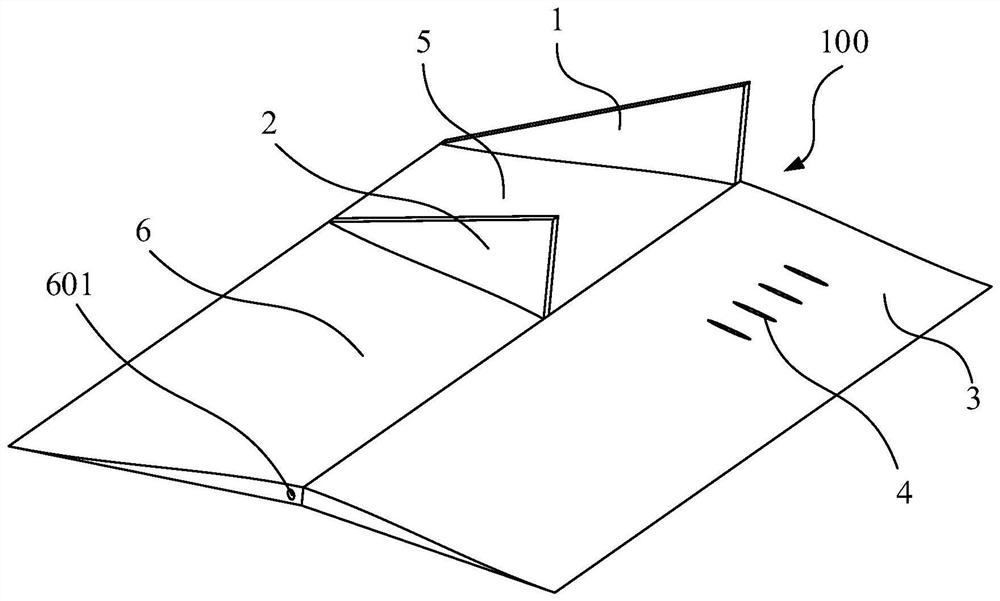

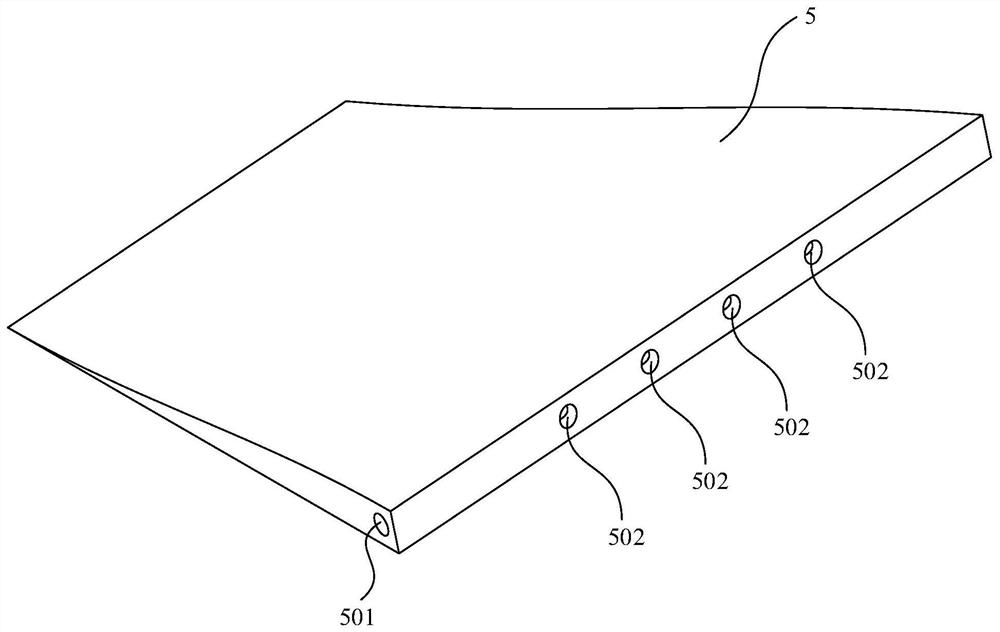

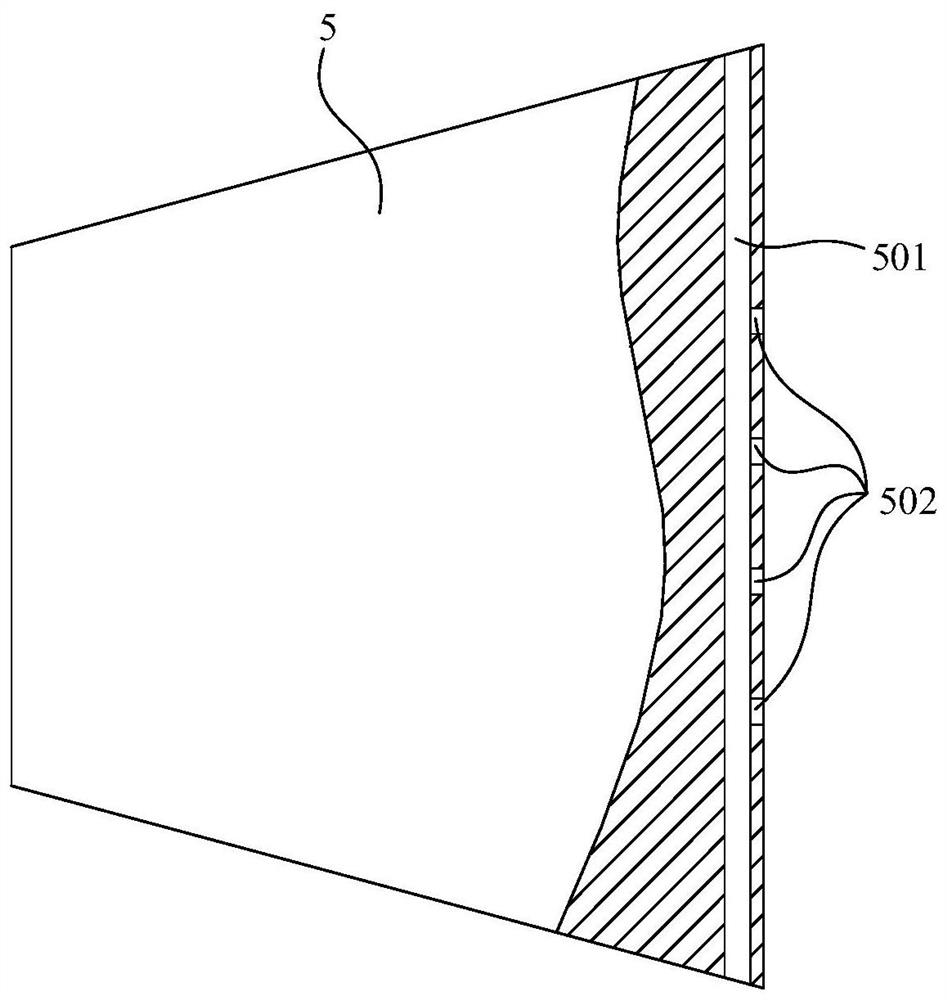

[0080] Such as Figure 1-9 As shown, it is an air flow control device in this embodiment, and the air flow control device includes at least one control unit 100, wherein the control unit 100 includes two opposite vertical plates and an exhaust assembly, between the two vertical plates The distance from the front to the rear gradually increases, and the exhaust assembly has an exhaust hole 4 capable of injecting gas, and the exhaust hole 4 is located in the rear area between the two vertical plates. Wherein, when the exhaust hole 4 is set, the opening of the exhaust hole 4 faces the air flow direction passing through the area between the two vertical plates, so that the airflow direction of the exhaust hole 4 ejected gas and the incoming flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com