Testing device for gas-detonation-driven ultra-high-speed emission

A test device and ultra-high-speed technology, which is applied to the test of ammunition, weapon accessories, ammunition, etc., can solve the problems of the projectile's horizontal direction is not perfect uniform motion, not enough to completely analyze the experimental process, unable to analyze the test failure and other problems. The effect of easy system maintenance, rich experimental data and accurate time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

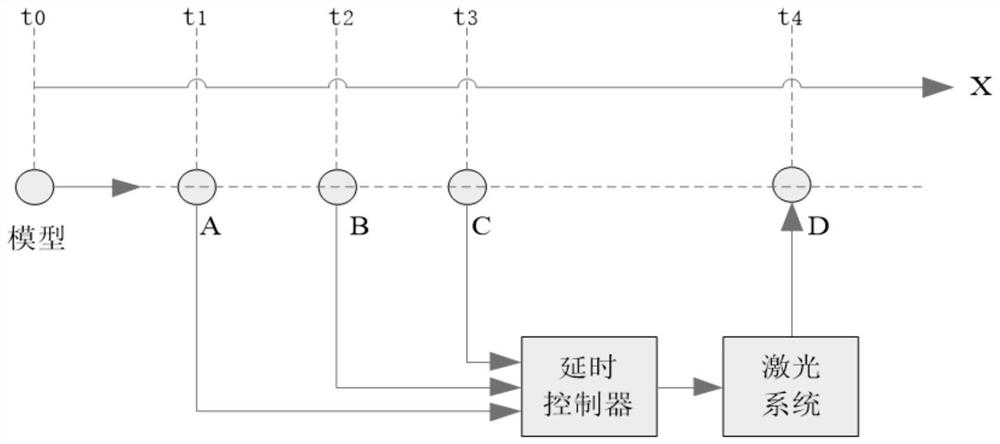

[0044] Such as figure 2 As shown, a gas detonation-driven ultra-high-speed launch test device includes a model and a target room measurement section at a certain distance from the model. A window and B window are respectively arranged at a certain distance in the target room measurement section. Four observation windows, window C, window D, window A, window B, and window C are respectively connected to the delay controller, and a laser system and a camera are installed at the position of window D, and the projectiles sequentially pass from the detection point A window, B window, C window When the window passes, the flight speed is calculated by calculating the flight time between adjacent detection windows, and then the delay time is calculated. The delay time is output by the delay controller to control the laser system to flash, and the projectile passes through the camera. Schlieren image of the D window.

[0045] Such as figure 2 As shown, if the three windows are trig...

Embodiment 2

[0056] On the basis of the embodiment, different from embodiment 1, a model of a gas detonation-driven ultra-high-speed emission test device adopts a two-stage structure design. The model includes a camera system for imaging, a measurement and control system for controlling flashes, and a processing and collection systems,

[0057] The photographing system includes a laser light source, a horizontal schlieren instrument, a vertical schlieren instrument, a collimating mirror, a reference flange, a window glass, a camera, and a camera controller. The straight mirror is equipped with a horizontal schlieren instrument and a vertical schlieren instrument, the laser light source is connected to the horizontal schlieren instrument through a horizontal optical fiber, and the laser light source is connected to the vertical schlieren instrument through a vertical optical fiber;

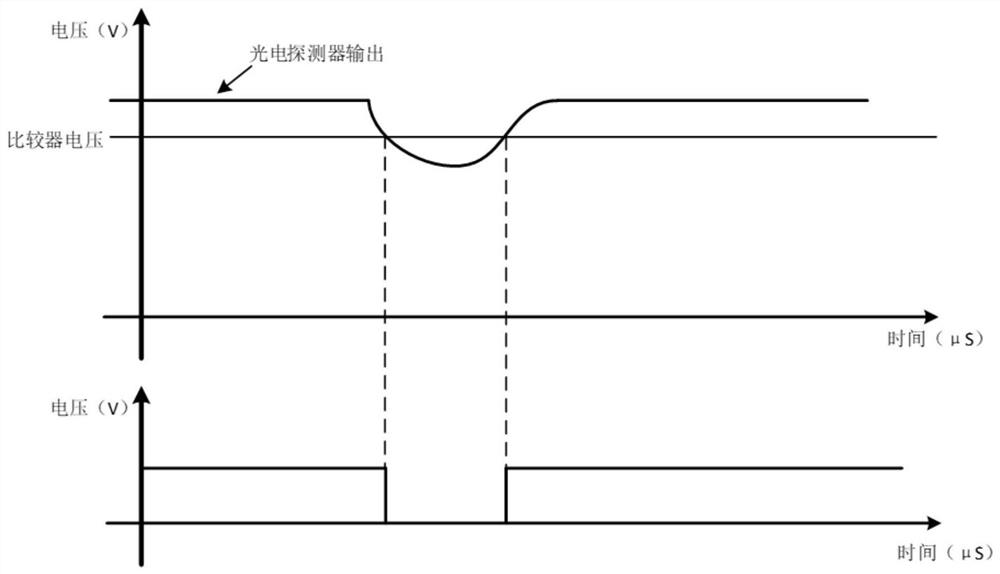

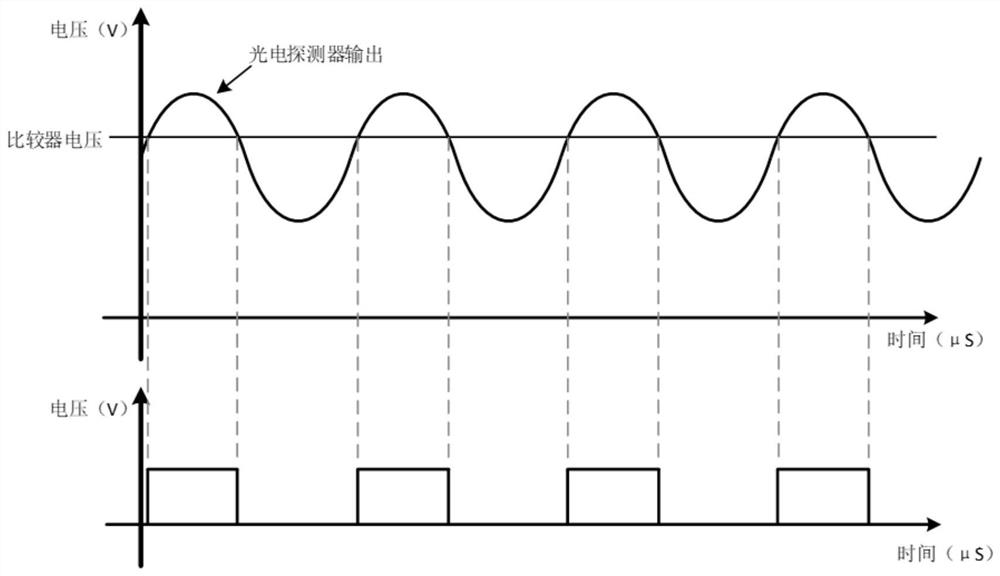

[0058] The measurement and control system for controlling the flash includes a laser light source, a photode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com