Patents

Literature

43results about How to "Fast error correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

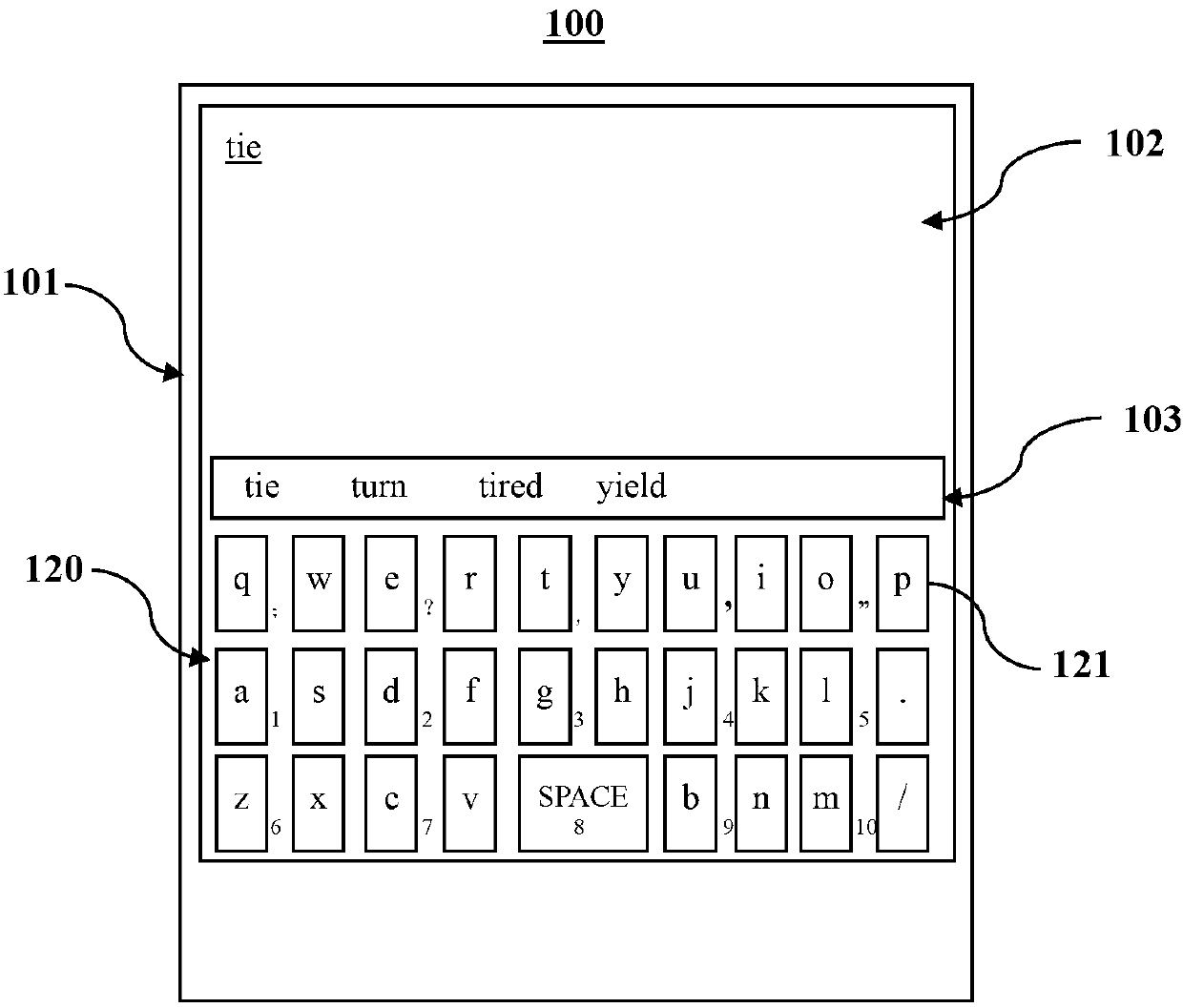

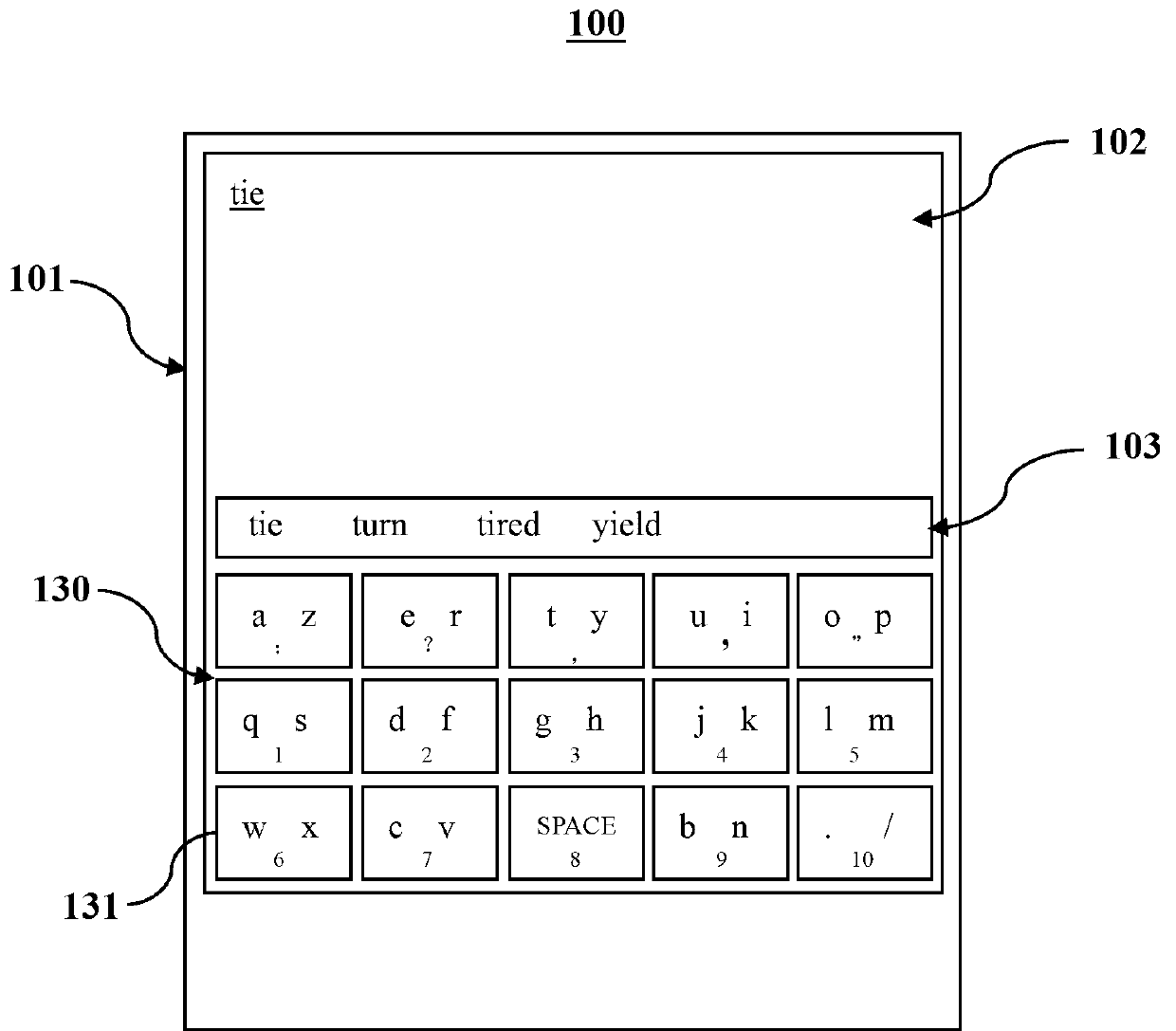

Input-method error correction method and input-method error correction device

ActiveCN104375665AImprove accuracyFast error correctionInput/output processes for data processingCorrection methodReal time display

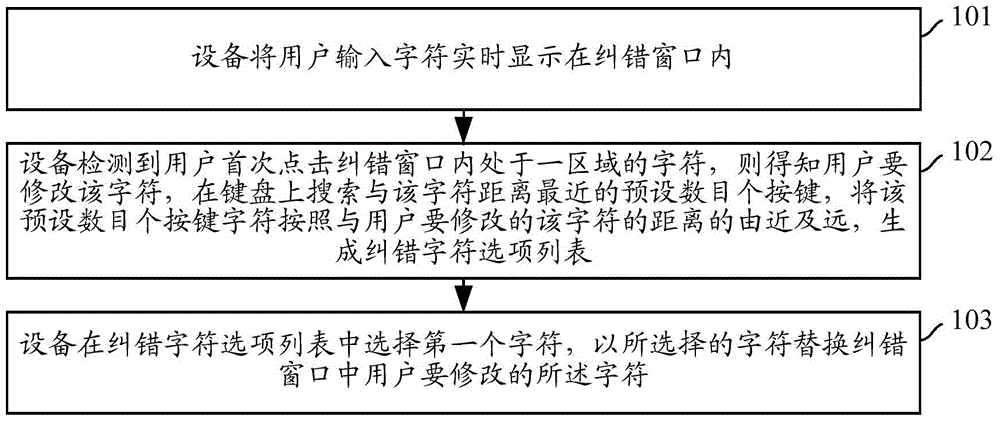

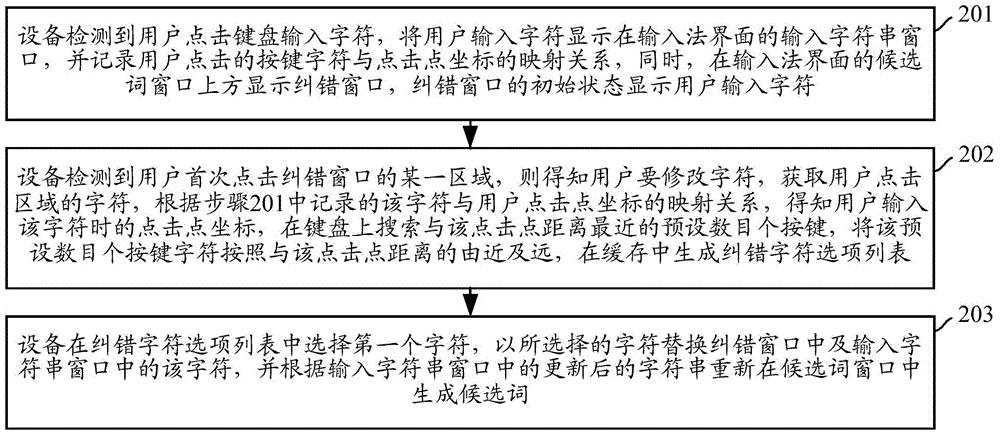

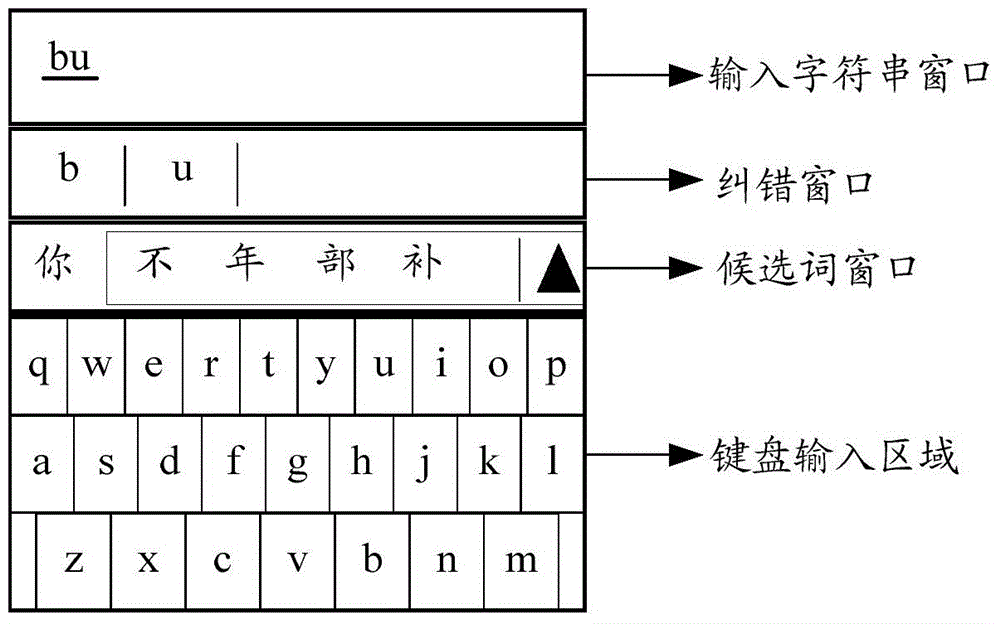

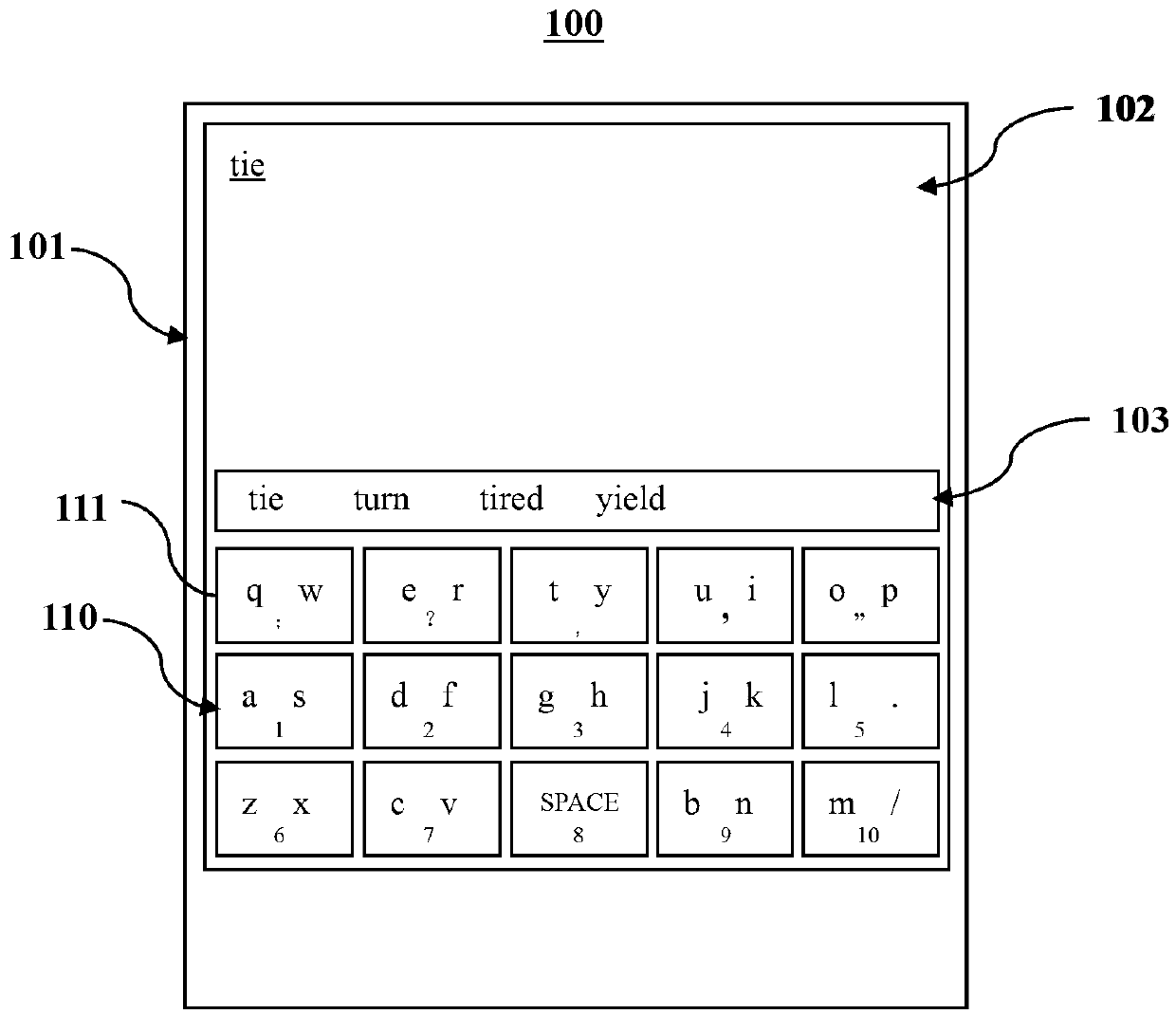

The invention provides an input-method error correction method and an input-method error correction device. The method includes that equipment displays a character inputted by a user in an error correction window in real time; the equipment detects that the user clicks the character, positioned in an area, in the error correction window for the first time to know that the user wants to correct the character, searches a preset number of keys, nearest to the character, on a keyboard, and generates a corrected-character option list in which characters of the keys are sorted from the near to the distant according to distances between the characters and the character to be corrected by the user; the equipment selects the first character in the corrected-character option list and substitutes the selected character for the character, to be corrected by the user, in the error correction window. By the input-method error correction method and the input-method error correction device, input-method error correction efficiency is improved.

Owner:SAMSUNG ELECTRONICS CHINA R&D CENT +1

Methods used for inputting text into electronic device and correcting error

InactiveCN103136196APractical error correction methodImprove accuracySpecial data processing applicationsInput/output processes for data processingWord selectionTheoretical computer science

The invention relates to a method used for correcting error according to input of a user. The method used for correcting the error according to the input of the user includes: detecting current error correction settings, wherein the detection at least includes whether to correct error and an error correction range; detecting the input of the user; carrying error correction according to the input of the user and obtaining a related character set, wherein the character set at least comprises error correction characters for correcting error which possibly happens to the input of the user; and seeking the character set comprising the error correction characters in a dictionary and obtaining candidate words. The invention further relates to a method used for inputting text into an electronic device. With the methods used for inputting the text into the electronic device and correcting the error, the user can self-define different keyboard layouts and switch among the different layouts freely. Meanwhile, automatic error correction can be achieved, intelligent word selection can be achieved with reference to the context, and the methods can greatly reduce design cost of a portable device manufacturer.

Owner:SHANGHAI CHULE (COOTEK) INFORMATION TECH CO LTD

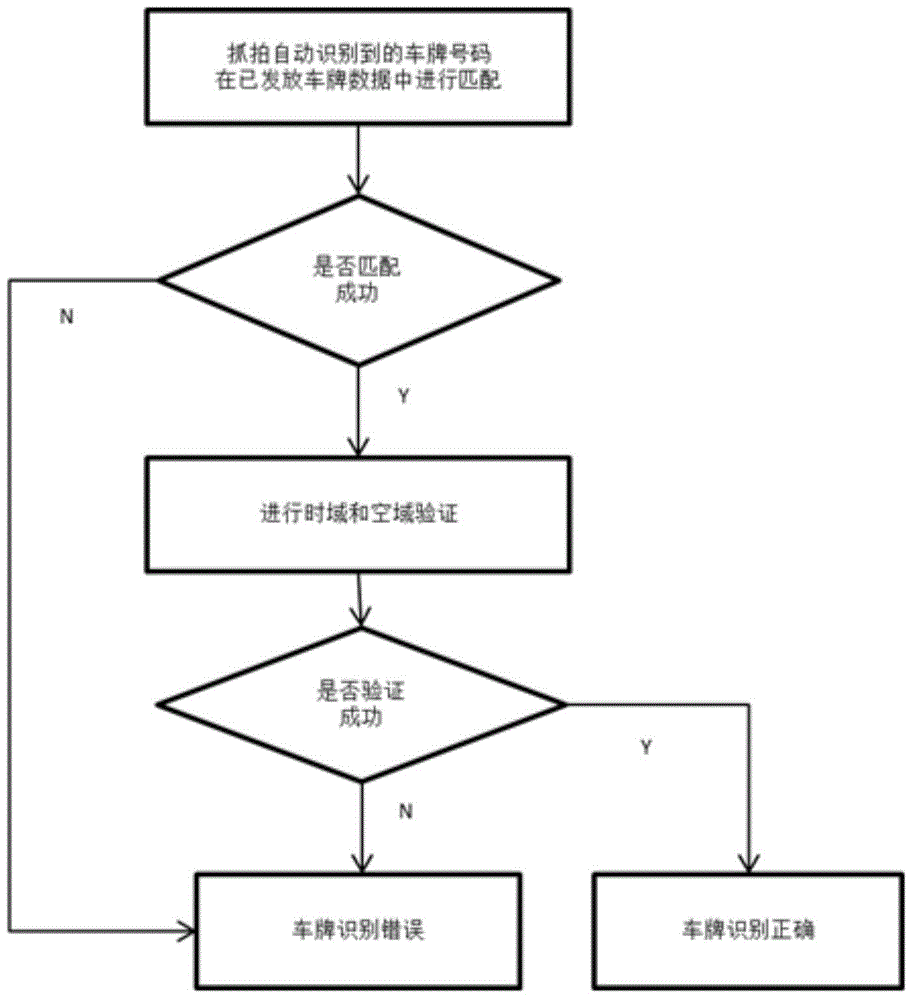

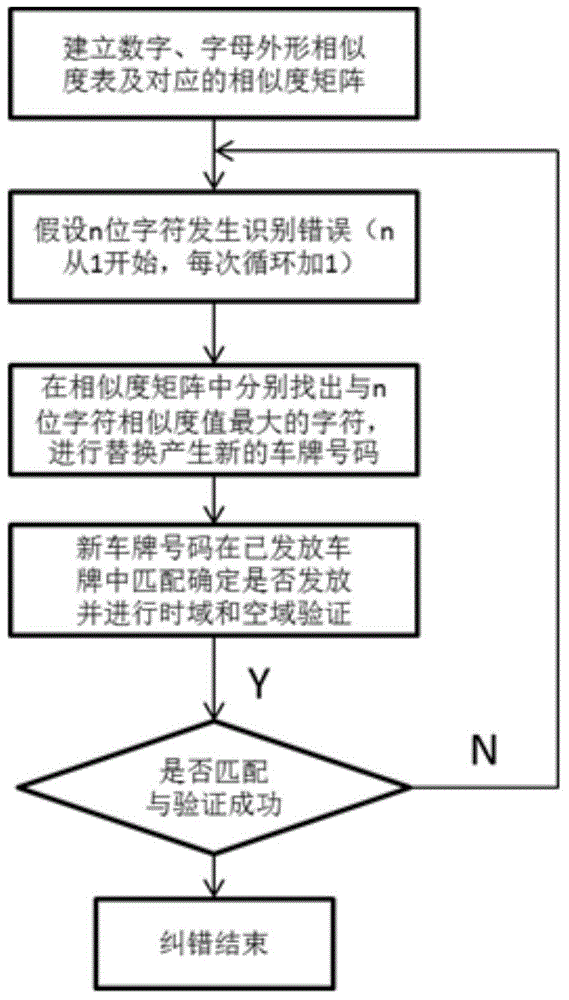

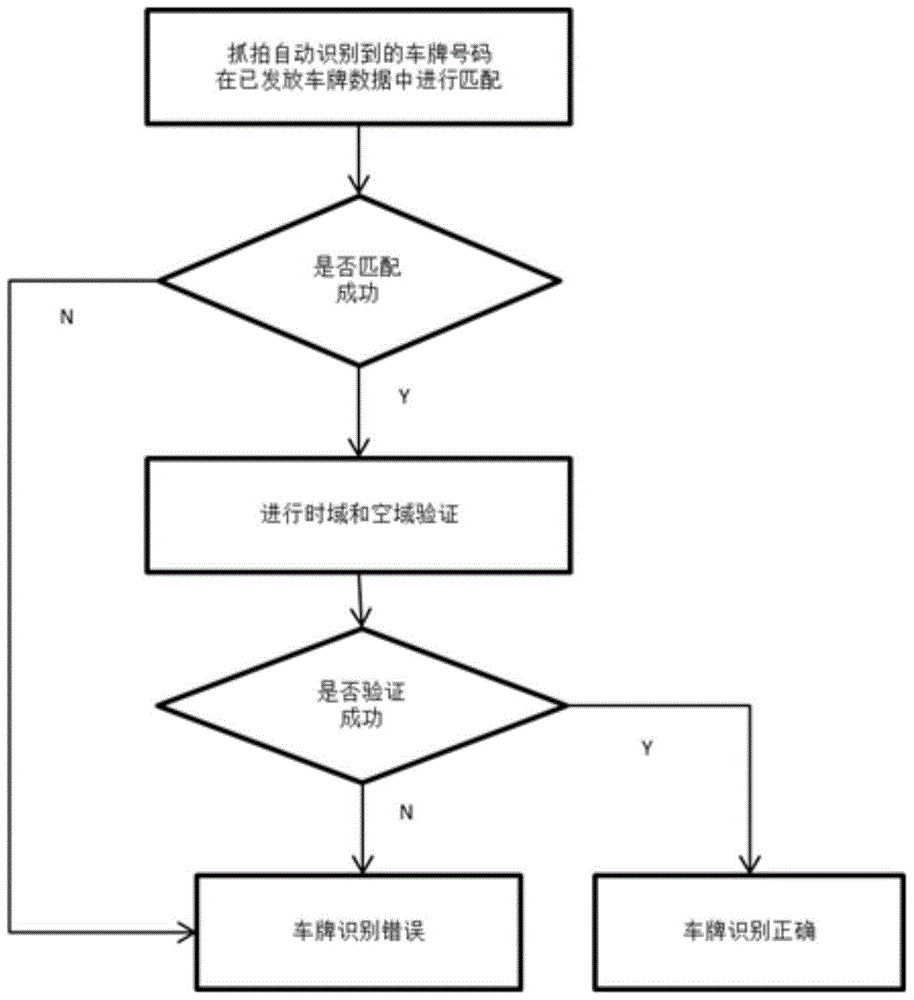

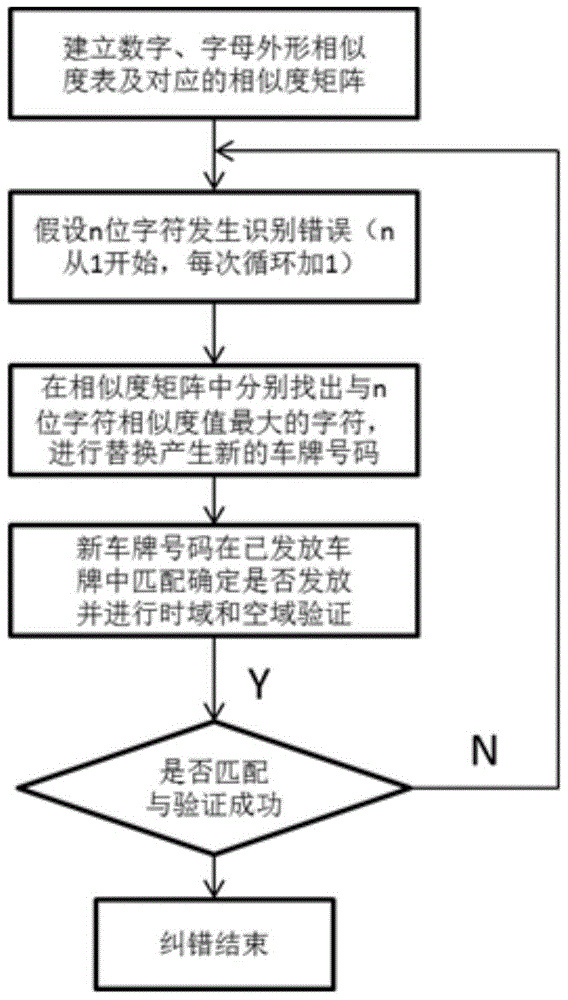

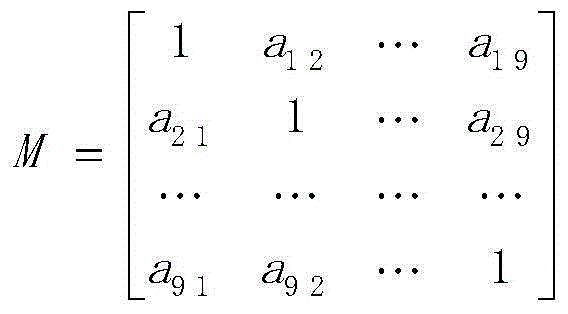

Method of correcting license plate number automatically recognized in traffic snapshot

ActiveCN105118300AFast error correctionImprove accuracyRoad vehicles traffic controlCharacter and pattern recognitionIn vehicleForward error correction

The invention discloses a method of correcting a license plate number automatically recognized in traffic snapshot. The method comprises steps: 1, error detection is carried out: license plate numbers in vehicle passing records are matched with the existing already-issued license plate numbers; and if a certain license plate number succeeds in matching in the above step, whether the license plate number is correctly recognized is verified next; and 2, error correction is carried out: through carrying out the above error detection on the license plate numbers, a large number of wrongly-recognized license plate numbers are obtained, and the error correction process is to correct the wrongly-recognized license plate numbers to be actually true license plate numbers of vehicles.

Owner:广东启功实业集团有限公司

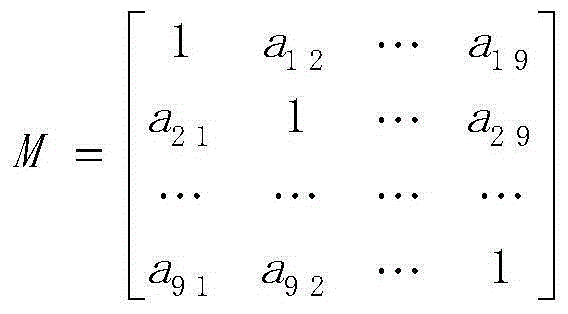

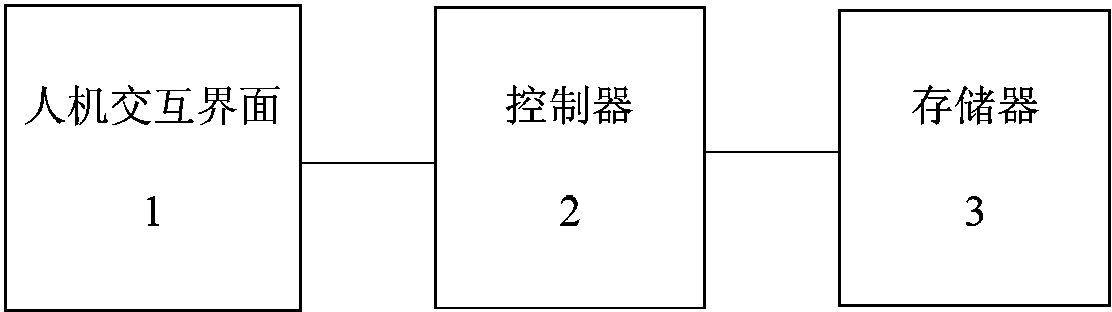

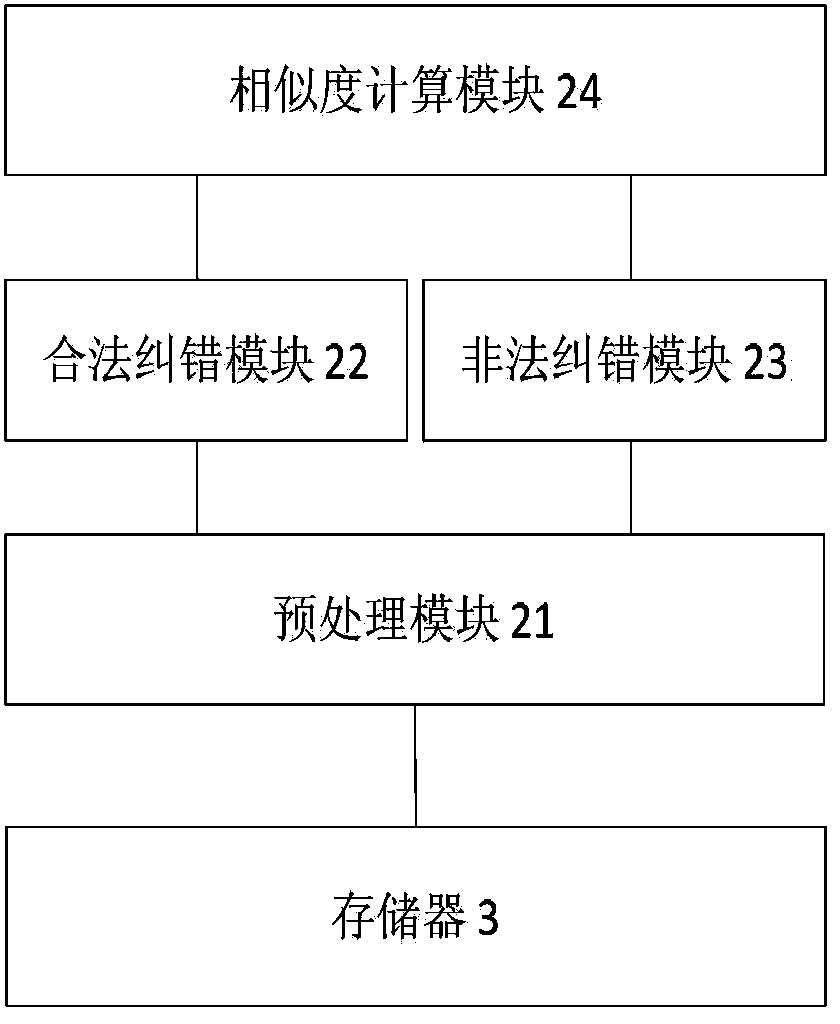

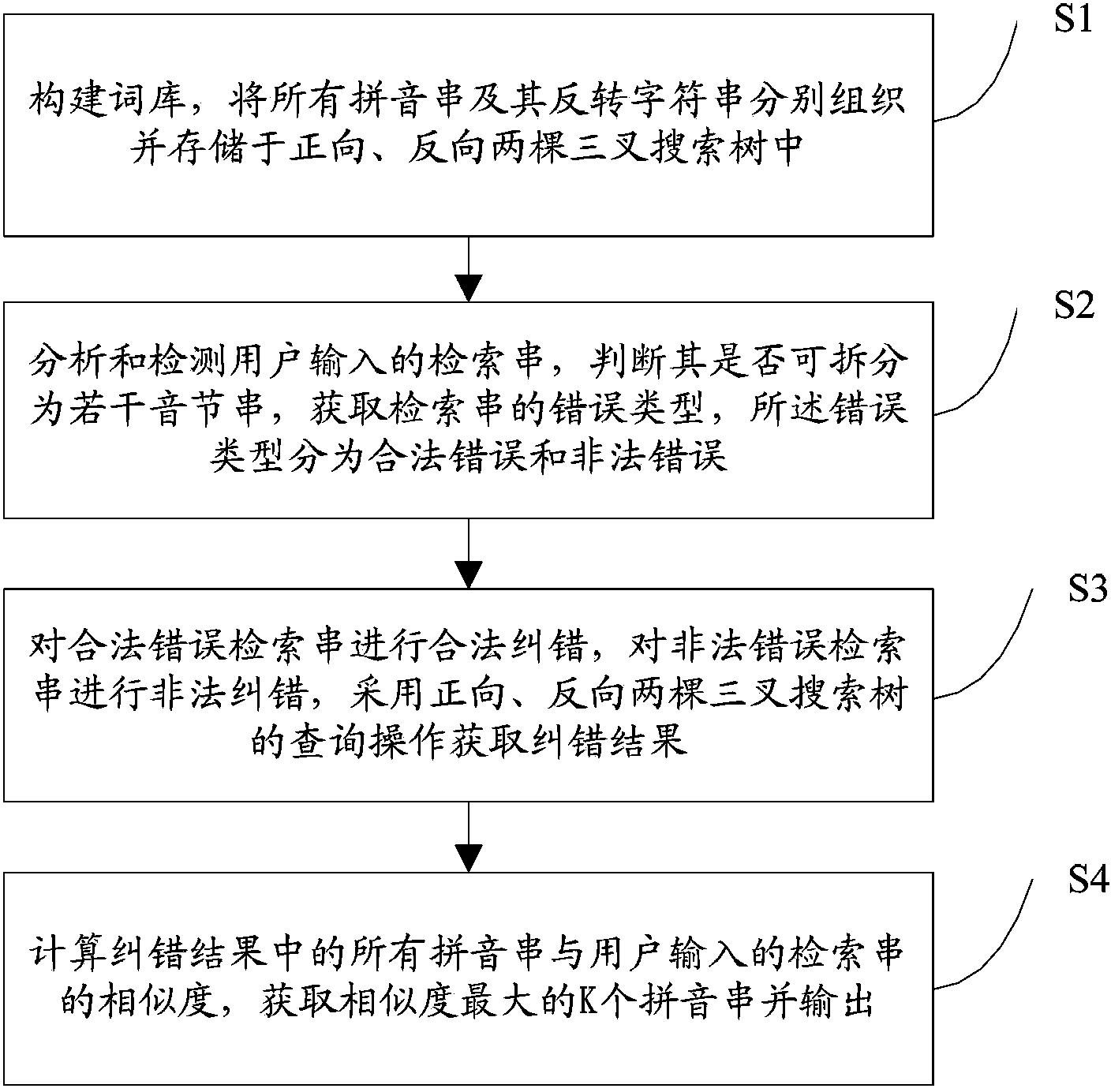

Pinyin error correction method and system

ActiveCN104252484APinyin error correction method is conciseImprove accuracySpecial data processing applicationsSyllableUser input

The invention provides a pinyin error correction method and system. The pinyin error correction method comprises the following steps: building a word bank, organizing all pinyin strings and reverse strings which can be retrieved by a user respectively, and storing the pinyin strings and the reverse strings in positive and negative ternary search trees; analyzing and detecting a retrieval string input by the user, judging whether the retrieval string can be split into a plurality of syllable strings or not, and acquiring the error type of the retrieval string, wherein the error type is classified into a legal error and an illegal error; performing legal error correction on a legal error retrieval string, performing illegal error correction on an illegal error retrieval string, and acquiring an error correction result by adopting inquiry operation of the positive and negative ternary search trees; computing the similarity of all pinyin strings and the retrieval string input by the user in the error correction result, acquiring K pinyin strings with highest similarity, and outputting the K pinyin strings. The pinyin error correction method provided by the invention has the advantages of simple and efficient design, high error correction speed and high accuracy.

Owner:NEW SINGULARITY INT TECHN DEV

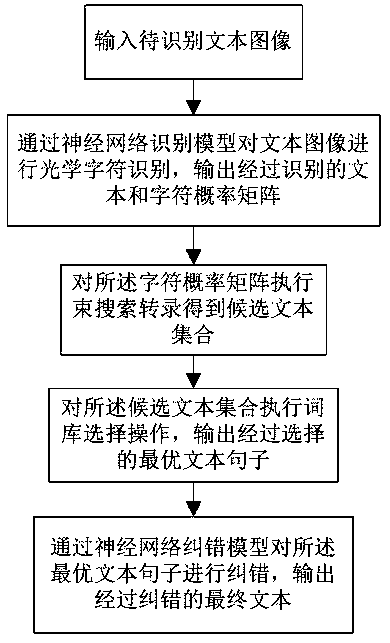

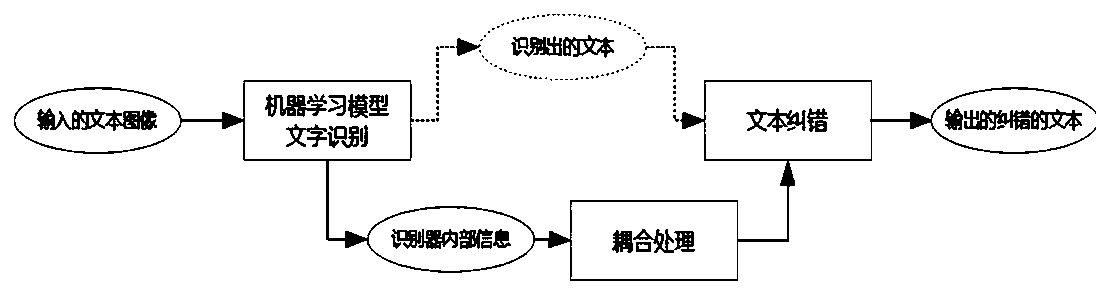

Text recognition method based on optical character recognition and error correction tight coupling processing

PendingCN111062376AThe recognition result is accurateFast error correctionSemantic analysisCharacter and pattern recognitionText recognitionNetwork model

The invention relates to a text recognition method based on optical character recognition and error correction tight coupling processing. According to the method, a text image is recognized through aneural network model, an optimal candidate text sentence is selected through text bundle search transcription and lexicon selection processing by utilizing internal information generated during text image recognition, error correction is performed through the neural network model, and a more accurate text recognition result is output. Optical character recognition and text error correction are tightly coupled, and compared with an existing loose coupling text recognition method, the text error correction performance can be effectively improved, and the text recognition accuracy is improved.

Owner:厦门商集网络科技有限责任公司 +1

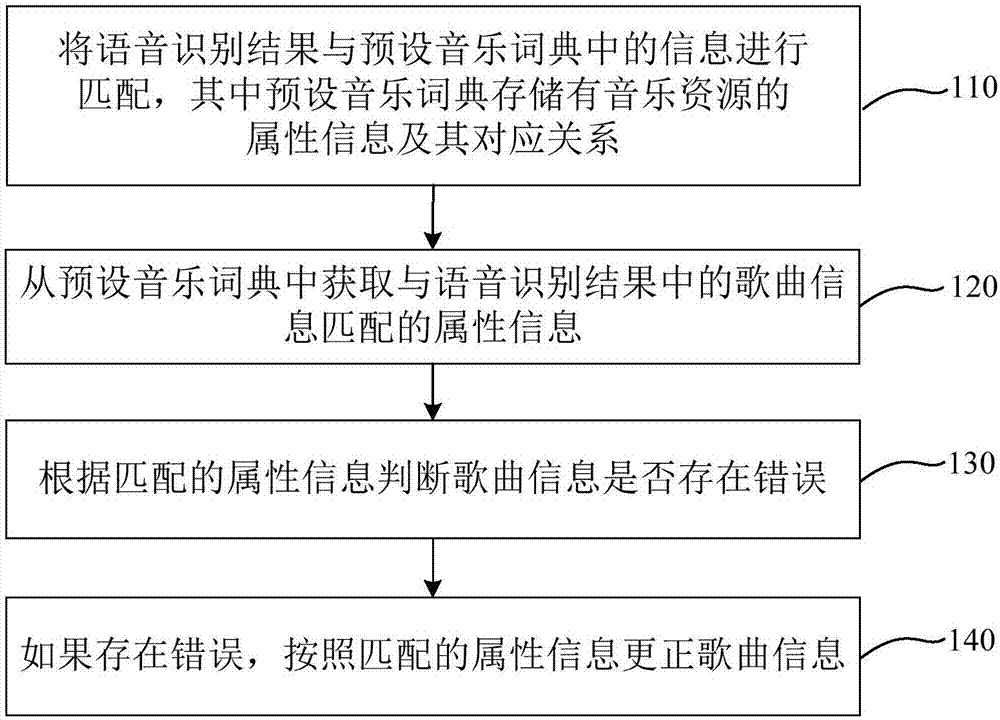

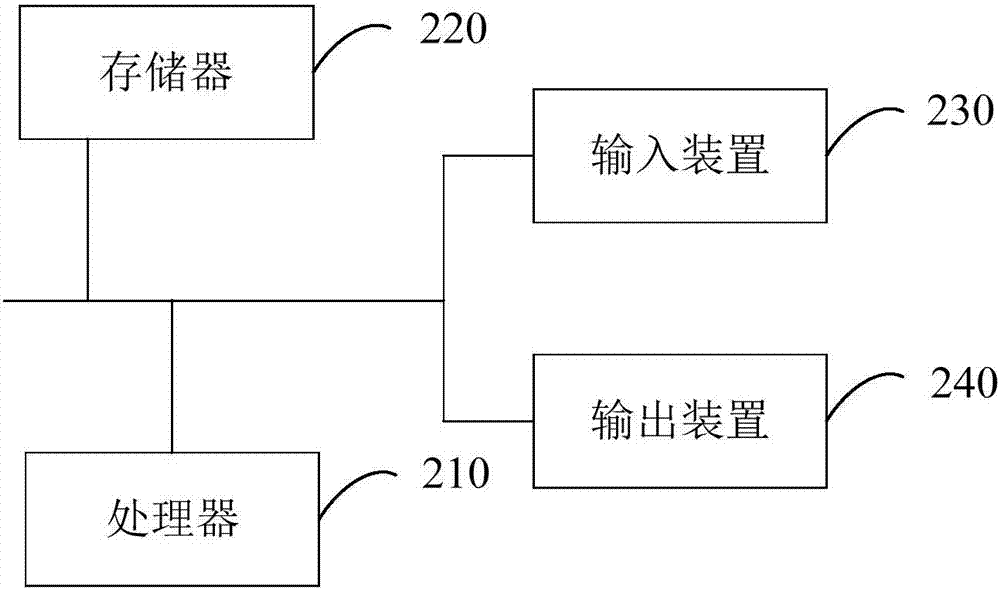

Voice error correction method used for requesting song through voice, terminal and storage medium

ActiveCN107239547AFast error correctionAvoid search errorsSpeech recognitionSpecial data processing applicationsComputer terminalSpeech sound

The invention discloses a voice error correction method used for requesting a song through voice, a terminal and a storage medium. The method comprises the steps that a voice recognition result is matched with information in a preset music dictionary, wherein the preset music dictionary stores the attribute information of music resources and the corresponding relation of the attribute information; the attribute information matched with the song information in the voice recognition result is obtained in the preset music dictionary; according to the matched attribute information, whether there are errors in the song information or not is judged; if there are errors, the song information is corrected according to the matched attribute information. Error correction is conducted on the voice recognition result through the preset music dictionary, the music resource retrieval errors caused by the mistaken voice recognition are avoided, and the success rate of music services is improved.

Owner:北京如布科技有限公司

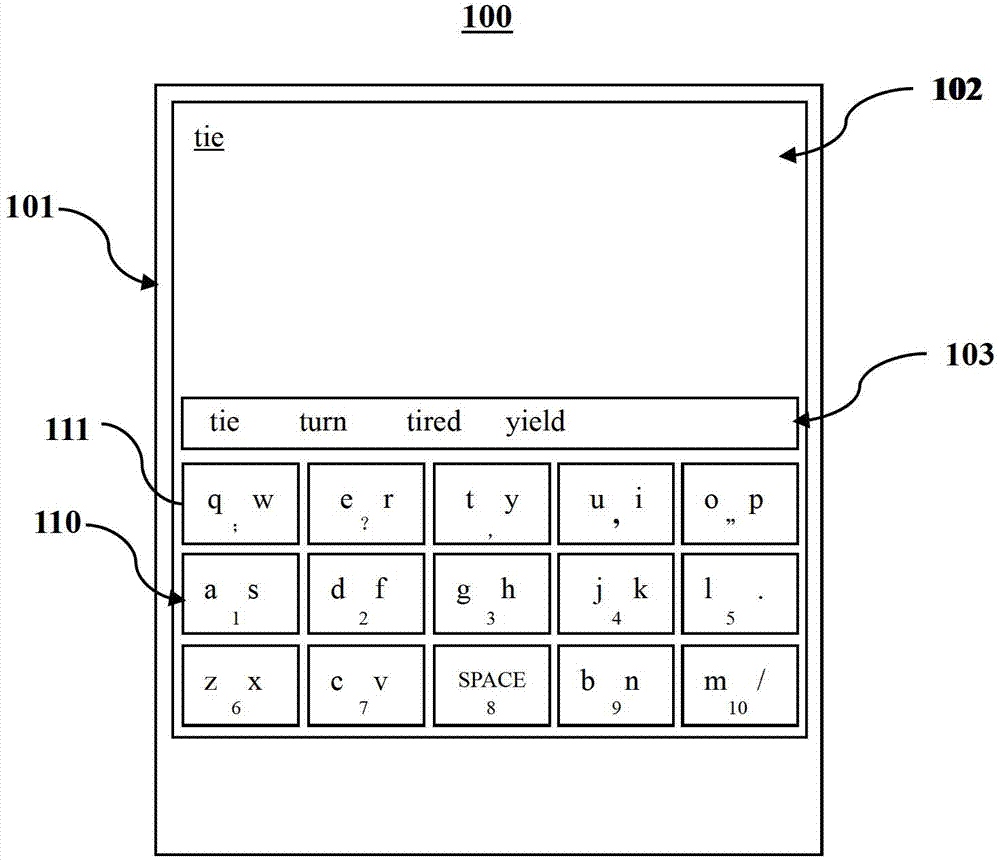

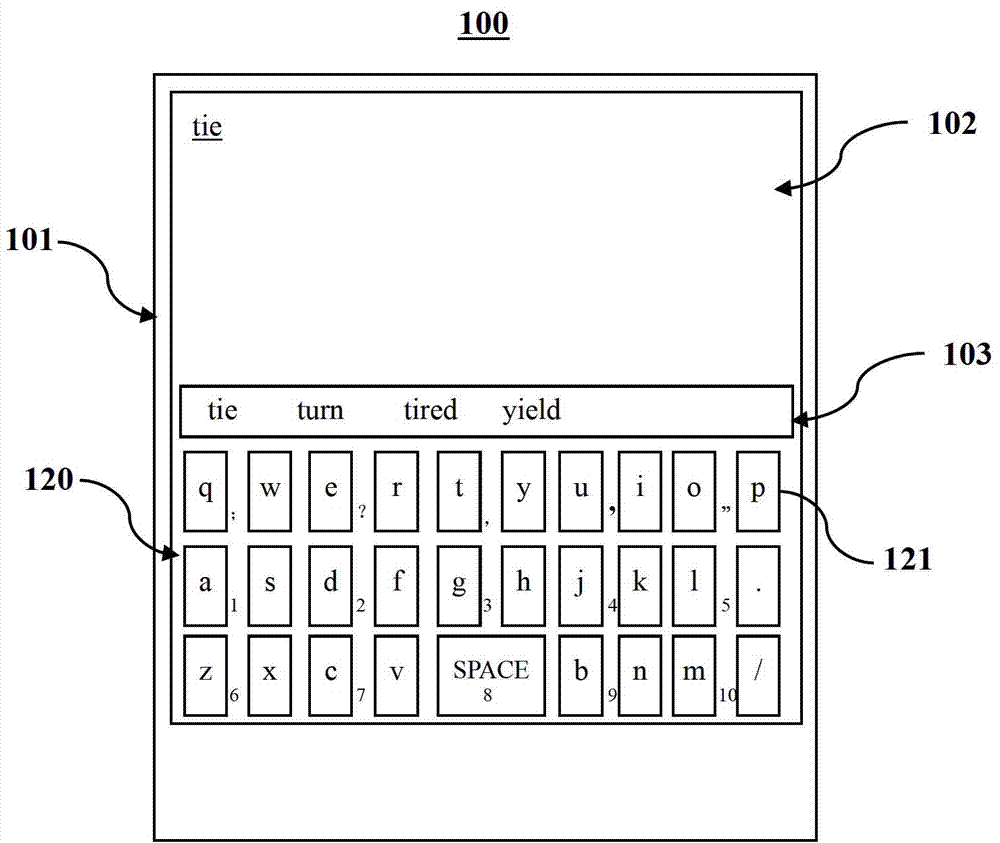

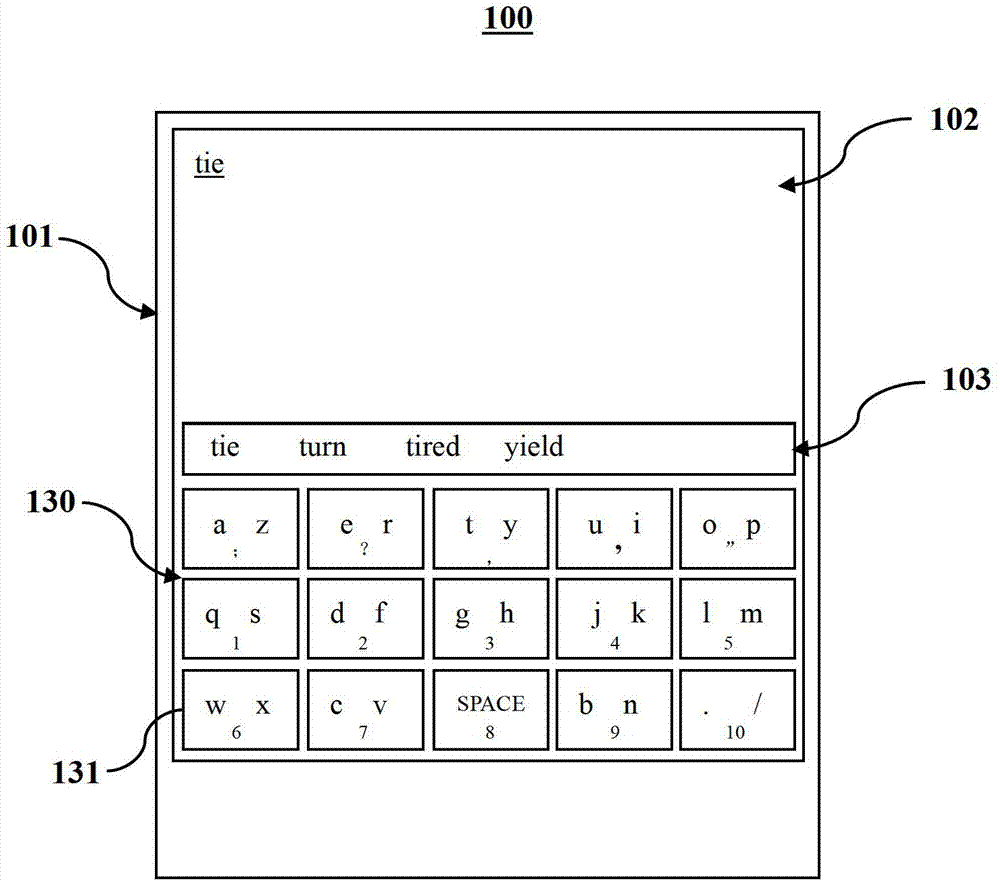

Keyboard layout switching method and keyboard layout adjusting method

ActiveCN103197765ASolve the problem of frequently pressing the wrong keyEffective error correction methodInput/output processes for data processingWord selectionUser input

The invention relates to a keyboard layout switching method, which comprises the following steps: displaying a first keyboard layout on a screen of display equipment, recording the input movement direction of a user when the fact that the user input moves within the area of the first keyboard layout is detected, and further, moving the first keyboard layout out of the screen in the movement direction and moving another keyboard layout into the screen in the movement direction. The invention further relates to a keyboard layout adjusting method. With adoption of the keyboard layout switching method and the keyboard layout adjusting method both disclosed by the invention, different keyboard layouts can be defined by the user and switched freely; meanwhile, automatic error correction can be realized, and intelligent word selection with reference to the context can be realized; and further, design cost for portable equipment manufacturers can be greatly reduced due to adoption of the methods.

Owner:SHANGHAI CHULE (COOTEK) INFORMATION TECH CO LTD

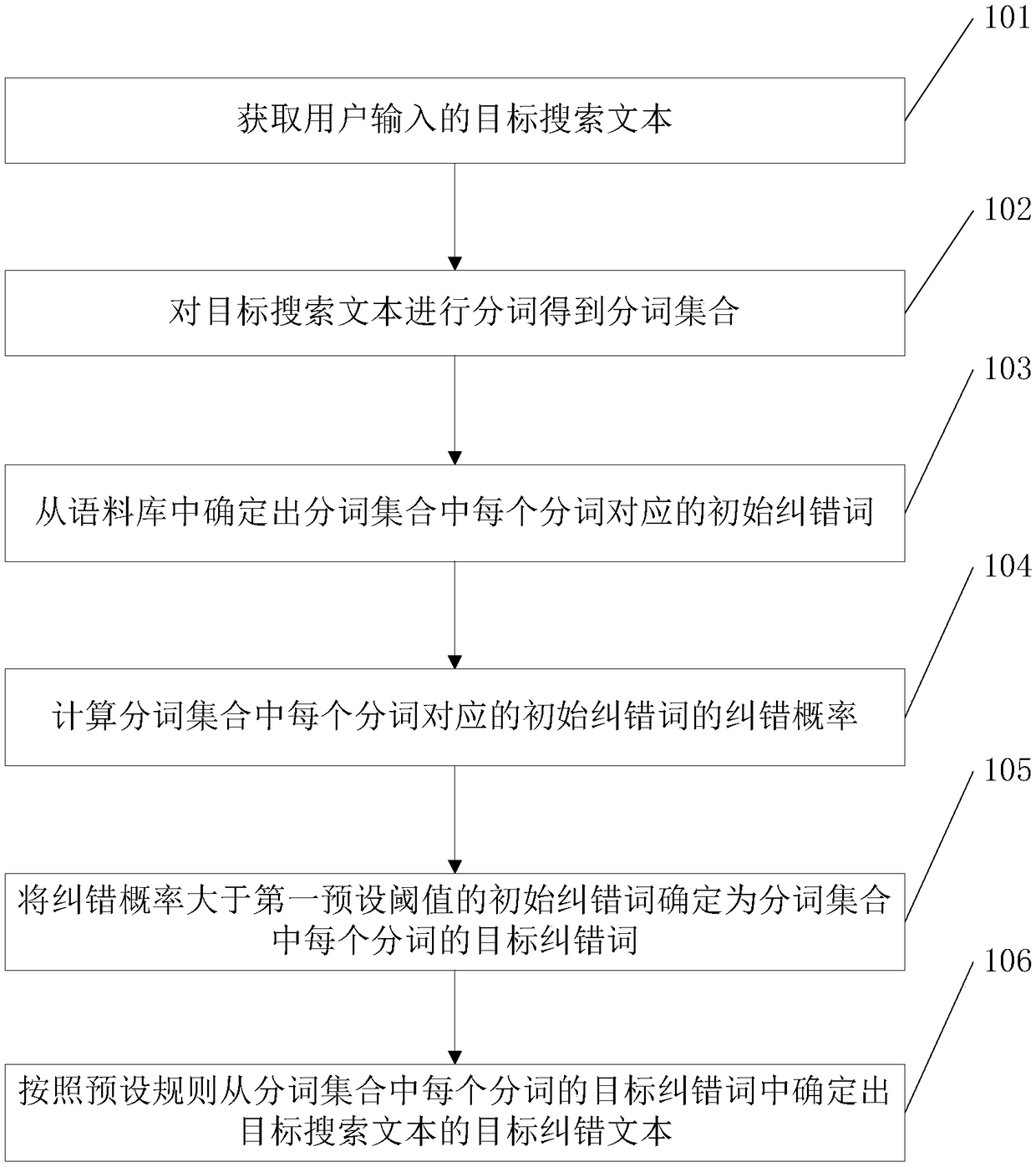

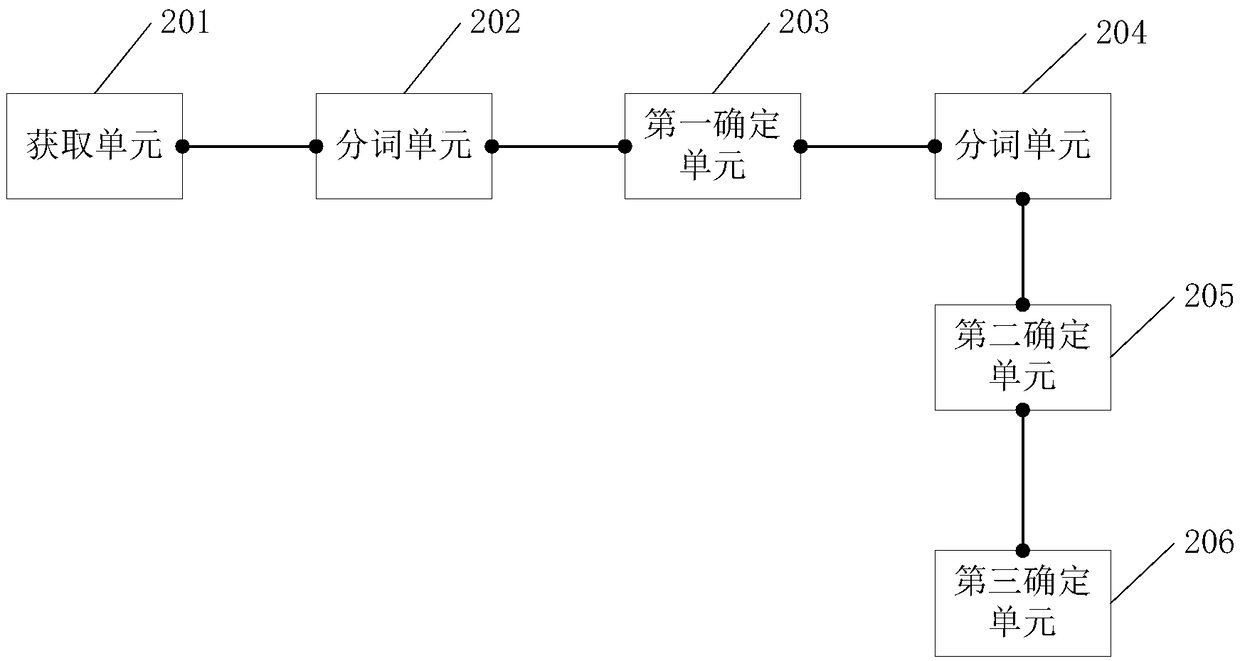

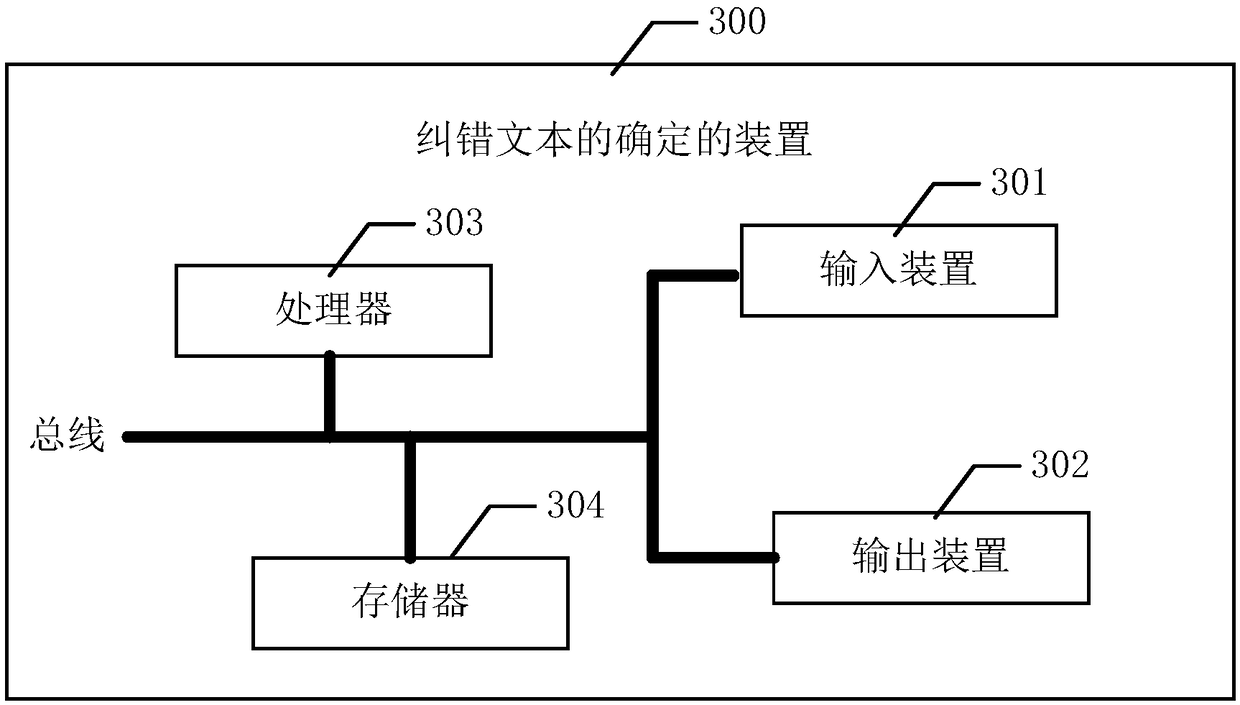

Method for determining error correction text and related equipment

PendingCN109376362AFast error correctionSmall amount of calculationNatural language data processingSpecial data processing applicationsAlgorithmUser input

The embodiment of the invention provides a method for determining error-correcting text and related equipment, which is used for improving the error-correcting speed of searching text. The method comprises the following steps of: obtaining a target search text input by a user; Segmentation of the target search text to obtain a segmentation set; Determining an initial error correction word corresponding to each participle in the participle set from a corpus; Calculating an error correction probability of an initial error correction word corresponding to each word in the word segmentation set; Determining an initial error correction word having an error correction probability greater than a first preset threshold value as a target error correction word for each word in the word segmentationset; A target error correction text of that target search text is determine from a target error correction word of each word in the word segmentation set according to a preset rule.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

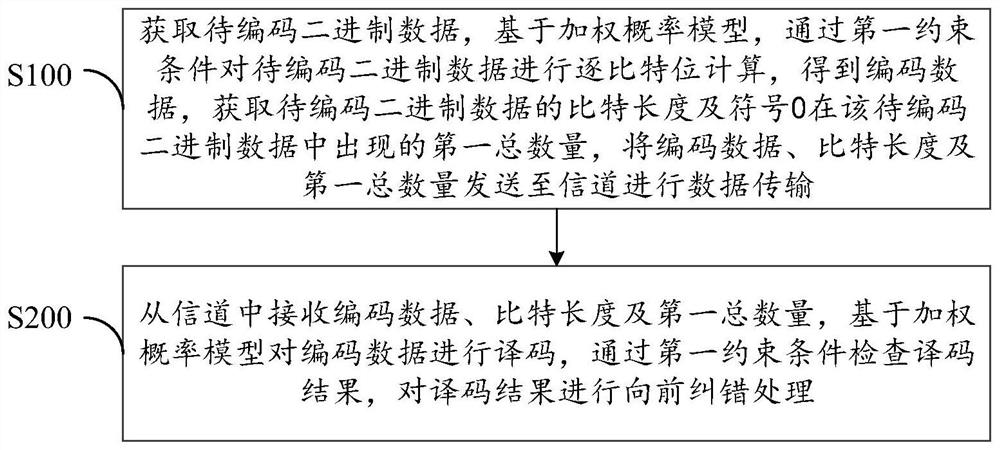

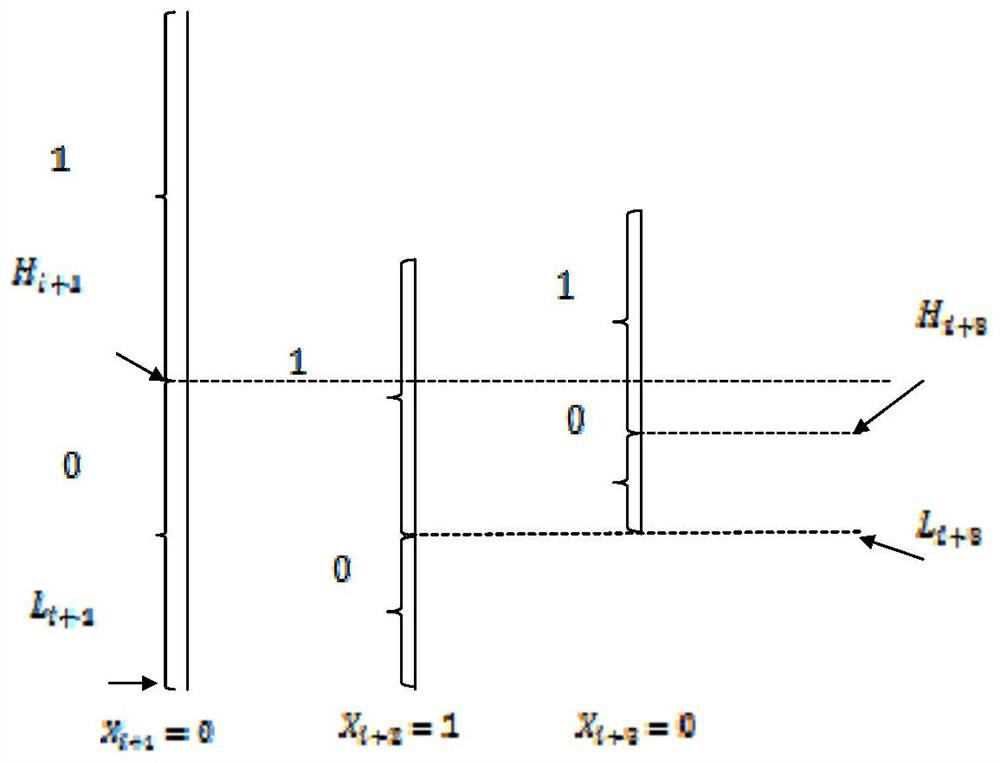

Jielin code error correction optimization method and device

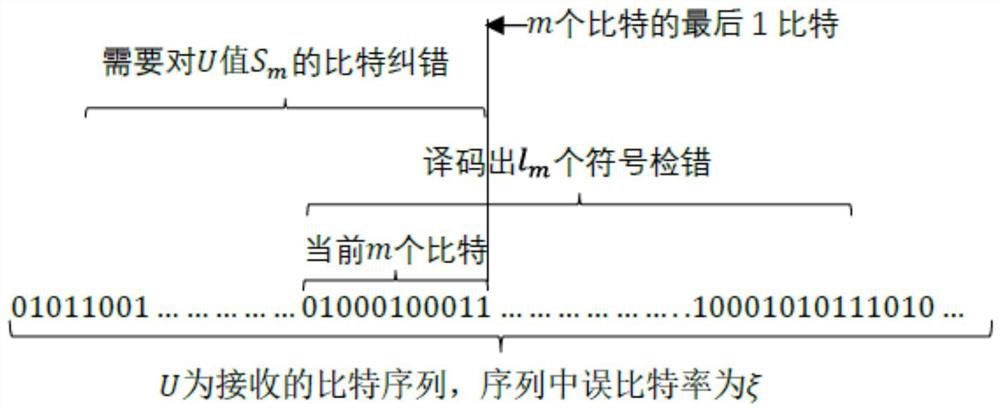

PendingCN112039531ALow resource requirementsFast error correctionCode conversionCoding detailsProbit modelLinear coding

The invention discloses a Jielin code error correction optimization method and device. The method comprises the steps: S100, obtaining to-be-coded binary data, carrying out the bit-by-bit calculationof the to-be-coded binary data through a first constraint condition based on a weighted probability model to obtain the coded data; then obtaining the bit length of the binary data to be coded and thefirst total number of symbols 0, and sending the coded data, the bit length and the first total number to a channel for data transmission; and S200, receiving the coded data, the bit length and the first total number from the channel, decoding the coded data based on the weighted probability model, checking a decoding result through the first constraint condition, and performing forward error correction processing on the decoding result. According to the invention, the data transmitted in the channel is linearly encoded and decoded through the weighted probability model, so that the requirement on hardware resources is low, the error correction speed is improved, and the error correction efficiency is further improved.

Owner:HUNAN YAOSHENG COMM TECH CO LTD

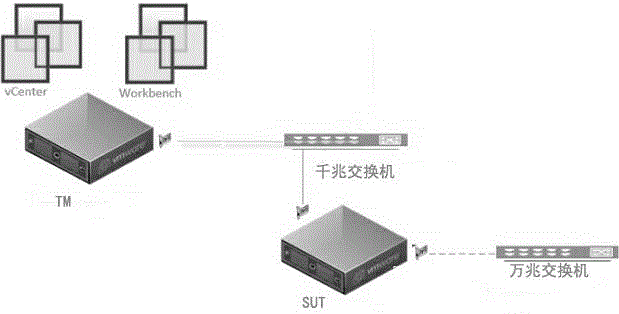

Method for verifying server in compliance with vSAN standard

InactiveCN104572376AQuick and Easy vSAN CompatibilityShort cycleDetecting faulty computer hardwareComputer hardwareGigabit

The invention discloses a method for verifying a server in compliance with the vSAN standard or not and relates to the system compatibility testing technology. The method includes adopting two servers, namely TM and SUT, with systems VMmre ESXi; allowing the TM to install a workbench as testing software, installing vCenter to manage the entire testing environment, connecting a gigabit switcher to the management network access ports of the two servers, and connecting a 10G switcher to the testing network access ports; in the testing process, observing the progress and UI interface to monitor and handle problems, and grasping testing content and testing steps; after testing is completed, verifying the server components is in compliance with the vSAN standard or not according to the testing result. The vSAN compatibility of the tested server can be tested rapidly and conveniently, and the method has the advantages of simple configuration, short cycles and convenience for monitoring and checking.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

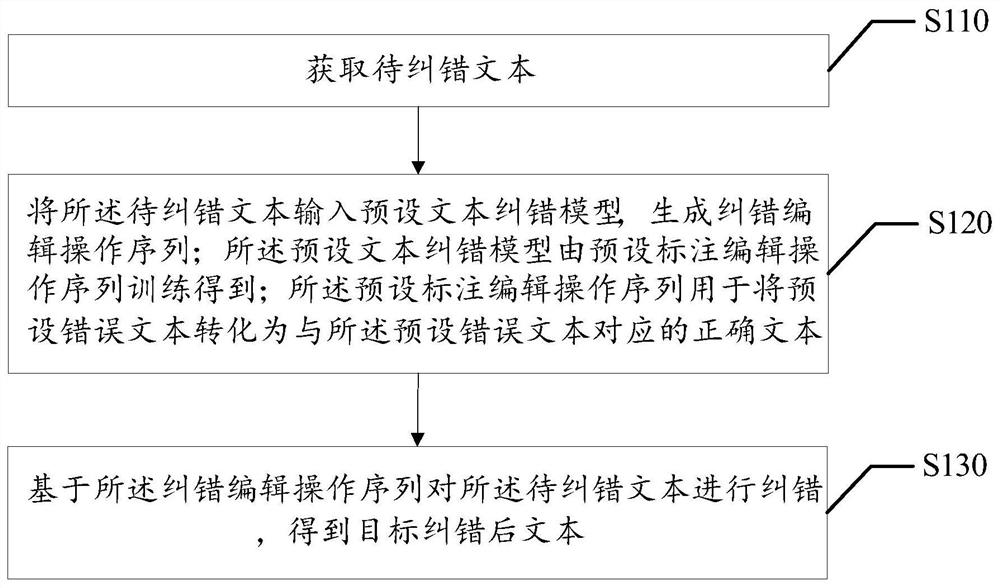

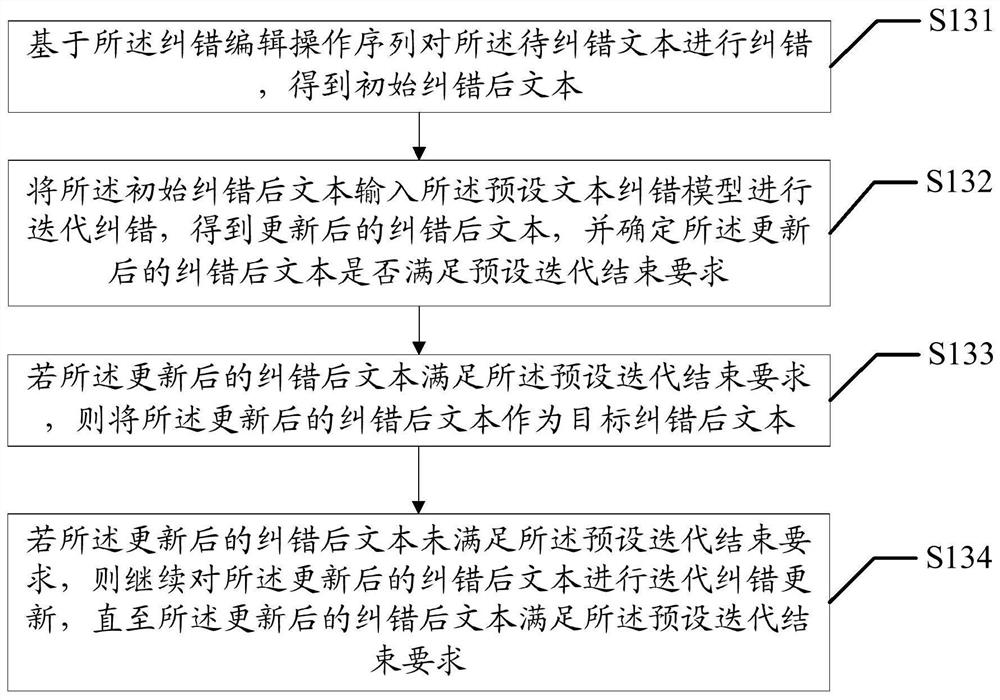

Text error correction method, device and equipment and readable storage medium

PendingCN112632912AEasy to correctFast error correctionCharacter and pattern recognitionNatural language data processingAlgorithmTransformation of text

The invention relates to the technical field of artificial intelligence, and discloses a text error correction method, device and equipment and a readable storage medium. The method comprises the following steps: inputting the text to be subjected to error correction into a preset text error correction model to generate an error correction editing operation sequence, wherein the preset text error correction model is obtained by training a preset annotation editing operation sequence, and the preset annotation editing operation sequence is used for converting a preset error text into a correct text corresponding to the preset error text; and performing error correction on the to-be-corrected text based on the error correction editing operation sequence to obtain an error-corrected text. According to the method and the device, the problem of time sequence dependence caused by crossed encoding of the encoder and decoding of the decoder is avoided, namely, the problem of text error correction is converted into the problem of sequence generation, so that the processes of generating the error correction editing operation sequence and converting the error text into the correct text can be parallel; and the error correction speed of the text error correction process is increased.

Owner:PING AN TECH (SHENZHEN) CO LTD

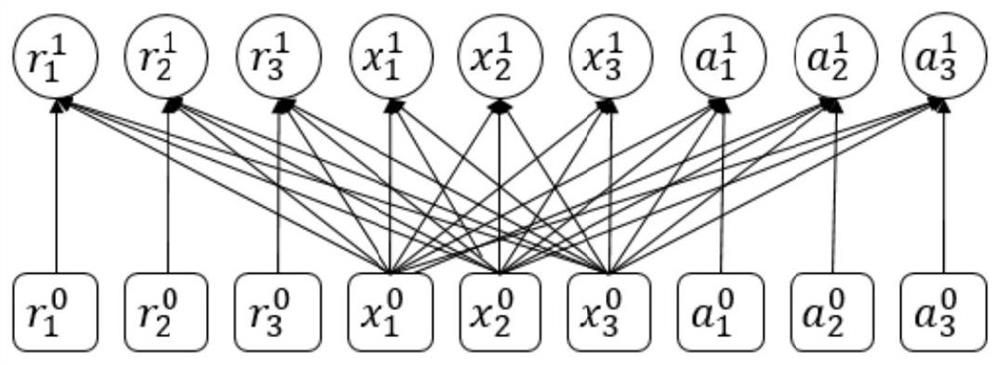

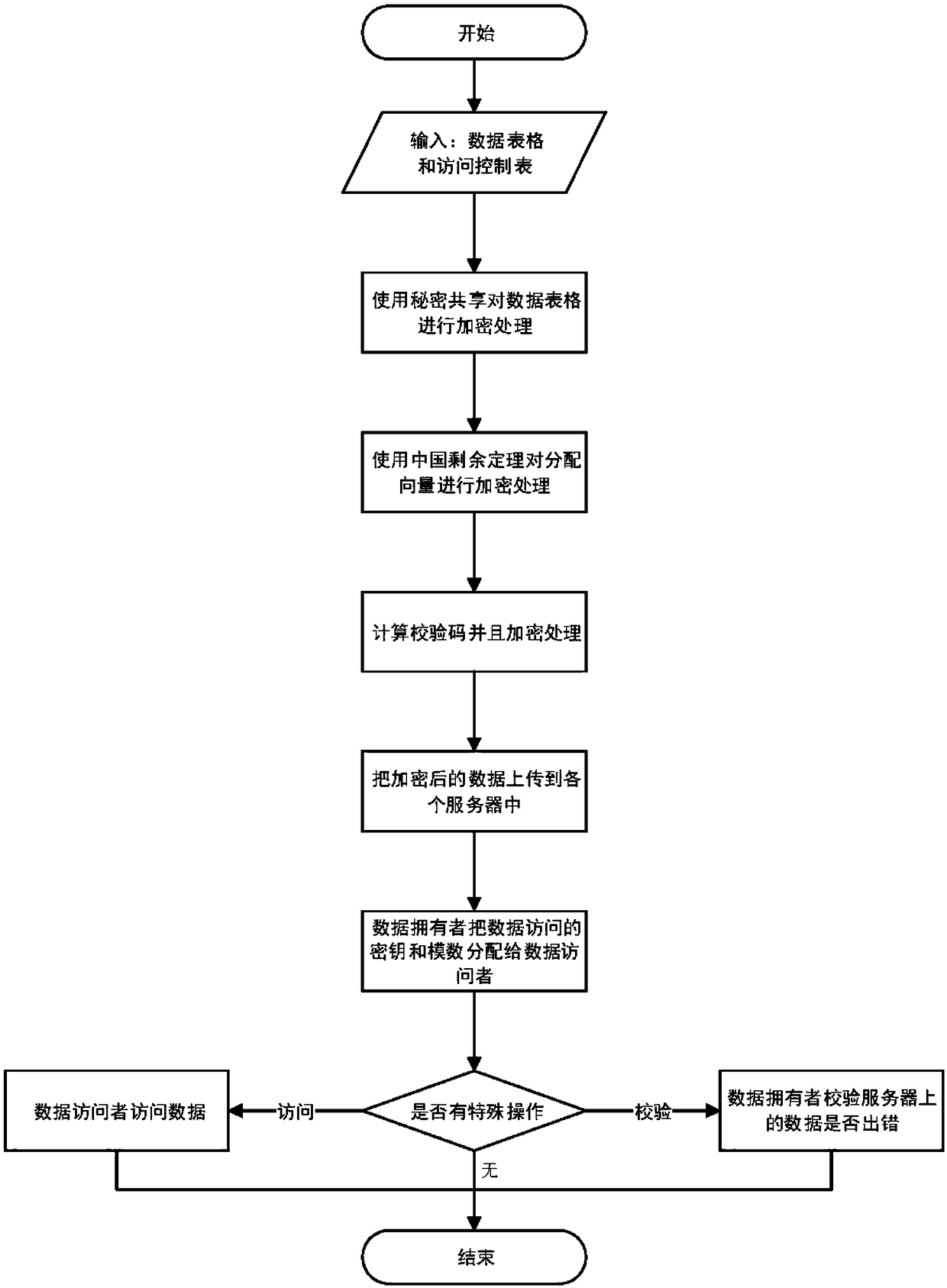

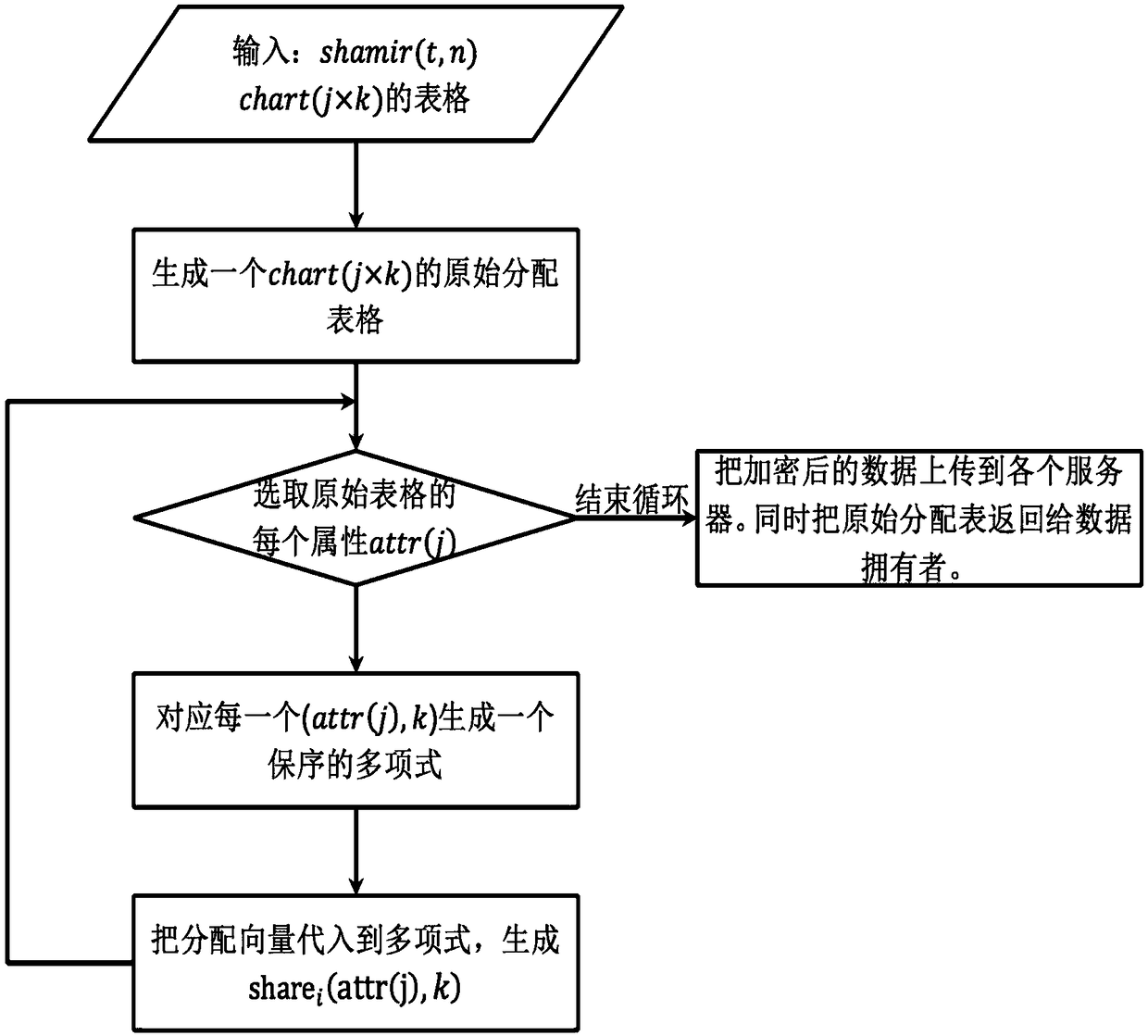

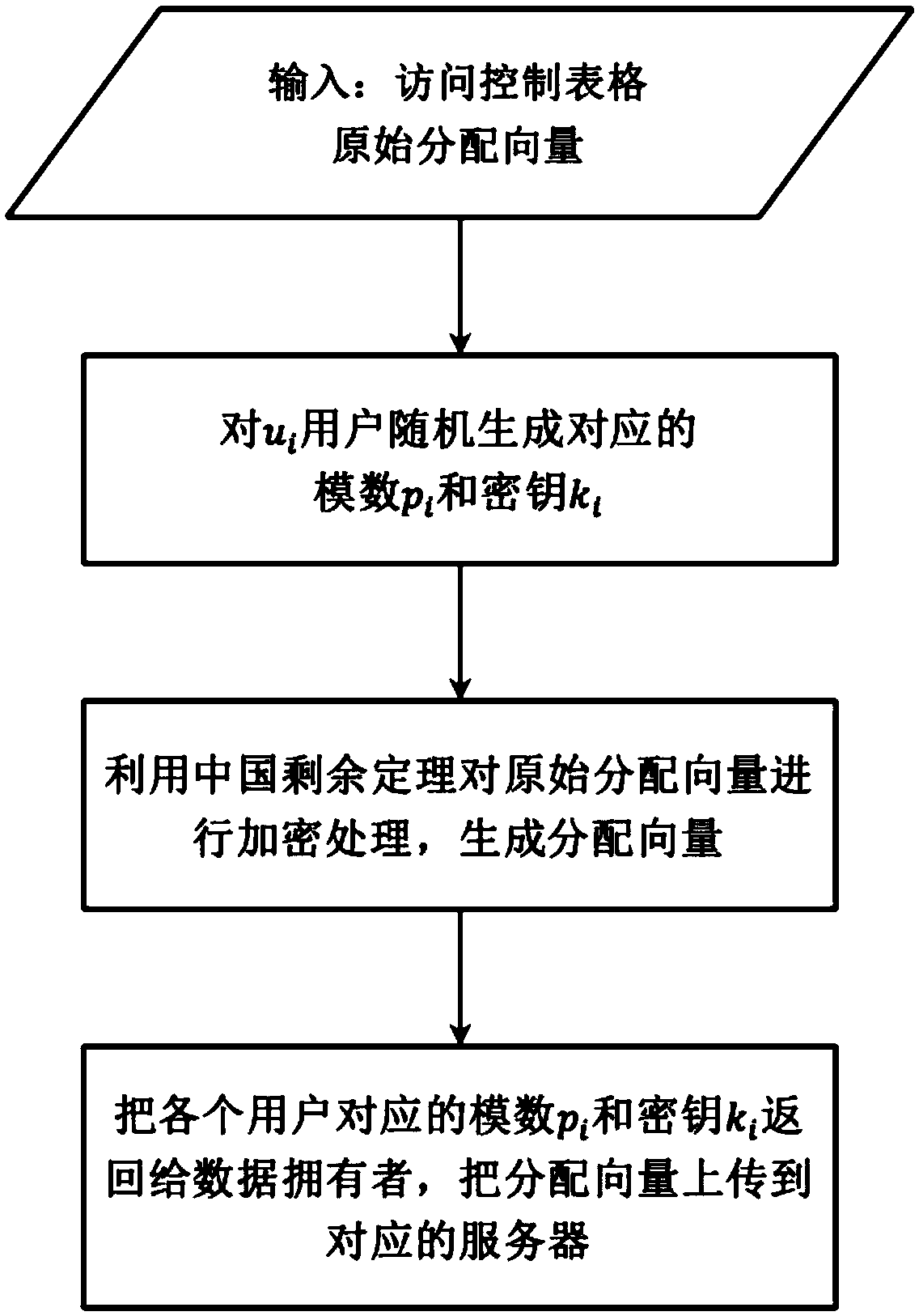

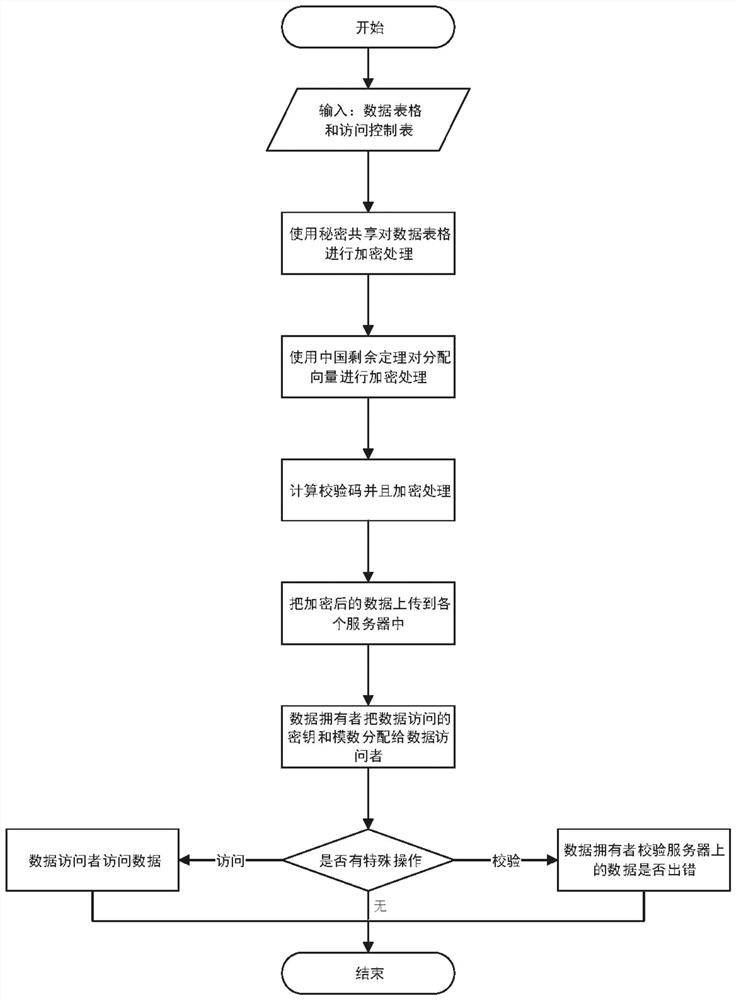

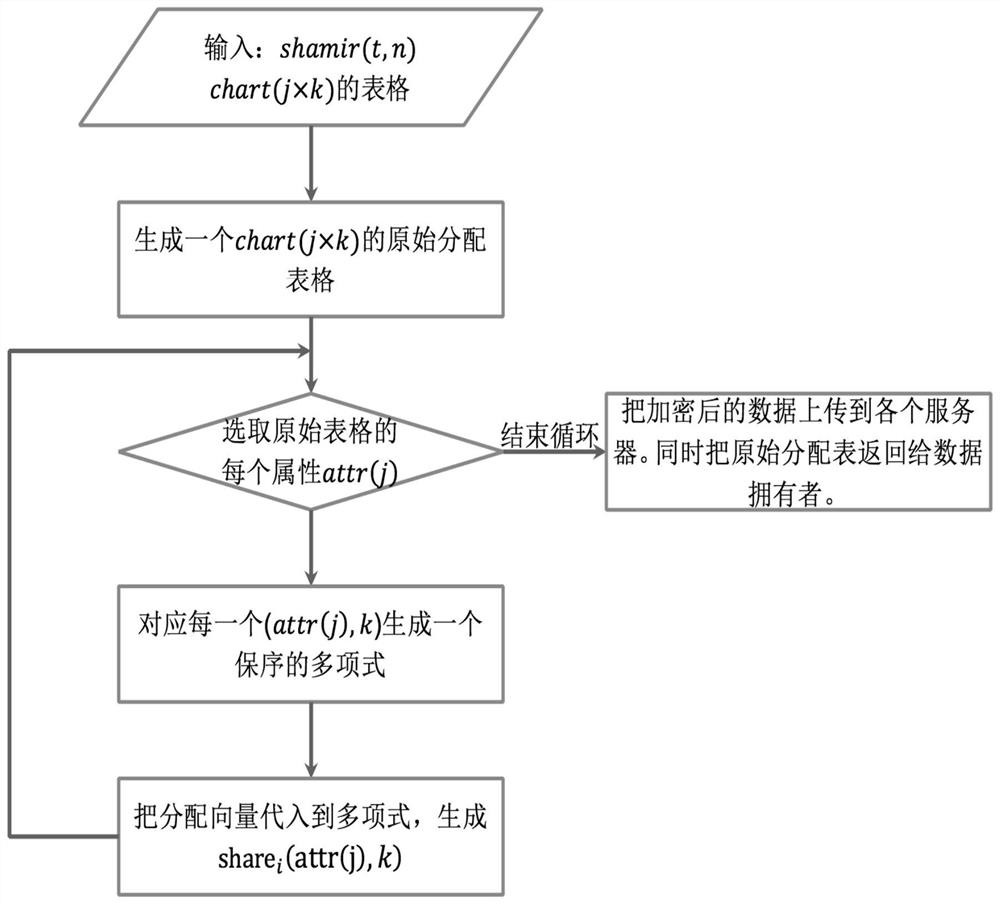

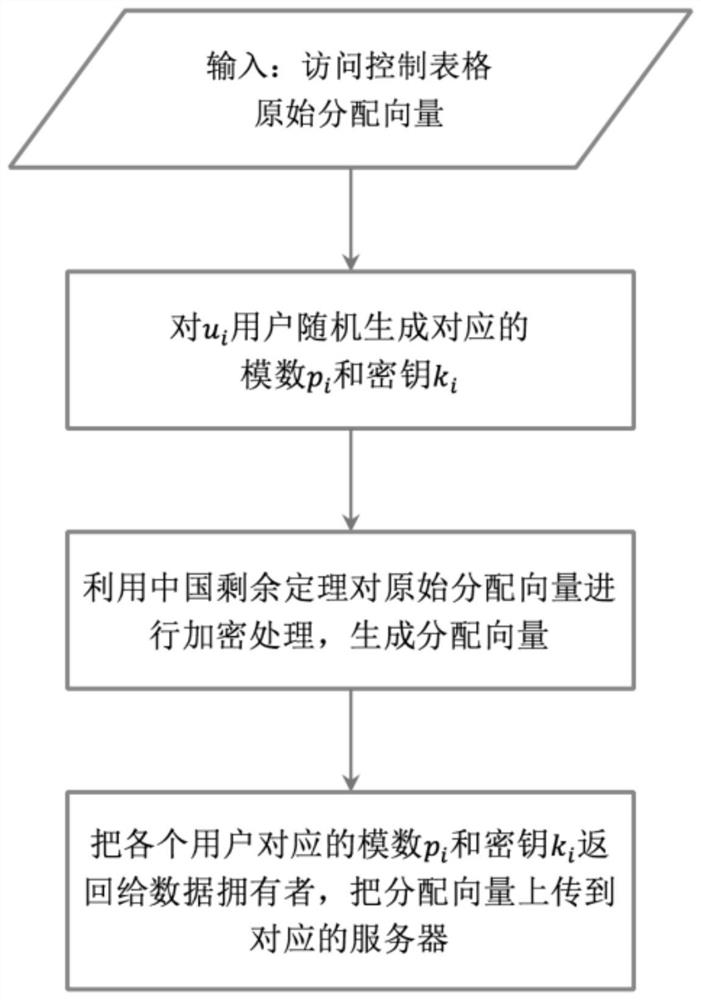

Verifiable database encryption retrieval method and system based on secret sharing

ActiveCN108763940AQuick and easy error correctionQuick checkKey distribution for secure communicationDigital data protectionComputer hardwareChinese remainder theorem

The invention discloses a verifiable database encryption retrieval method based on secret sharing. The method comprises the steps that a database is established; to-be-encrypted data is stored into the database, and encryption is performed through secret sharing; a data accessor permission chart is made, data accessor permissions are determined, and the data accessor permission chart is stored into the database through Chinese remainder theorem processing; modulus solving is performed on the encrypted data, and check codes corresponding to attributes in each column are generated and uploaded to servers; and data accessors access the servers, wherein the data accessors with permissions can solve the data, and the data accessors without permissions cannot solve the data. According to the method, secret sharing and the Chinese remainder theorem are combined, the remainder of modulus solving performed by each piece of data on a corresponding allocation value is used as one check code, andon the basis of not reconstructing f(x), information on the servers is verified separately; and when part of the information has an error, which server has an error can be pointed out in combination with other servers, and error information can be corrected quickly and easily.

Owner:SOUTH CHINA AGRI UNIV

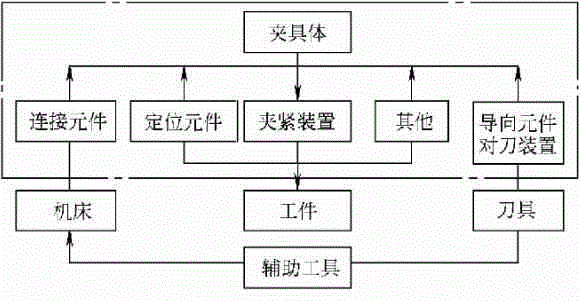

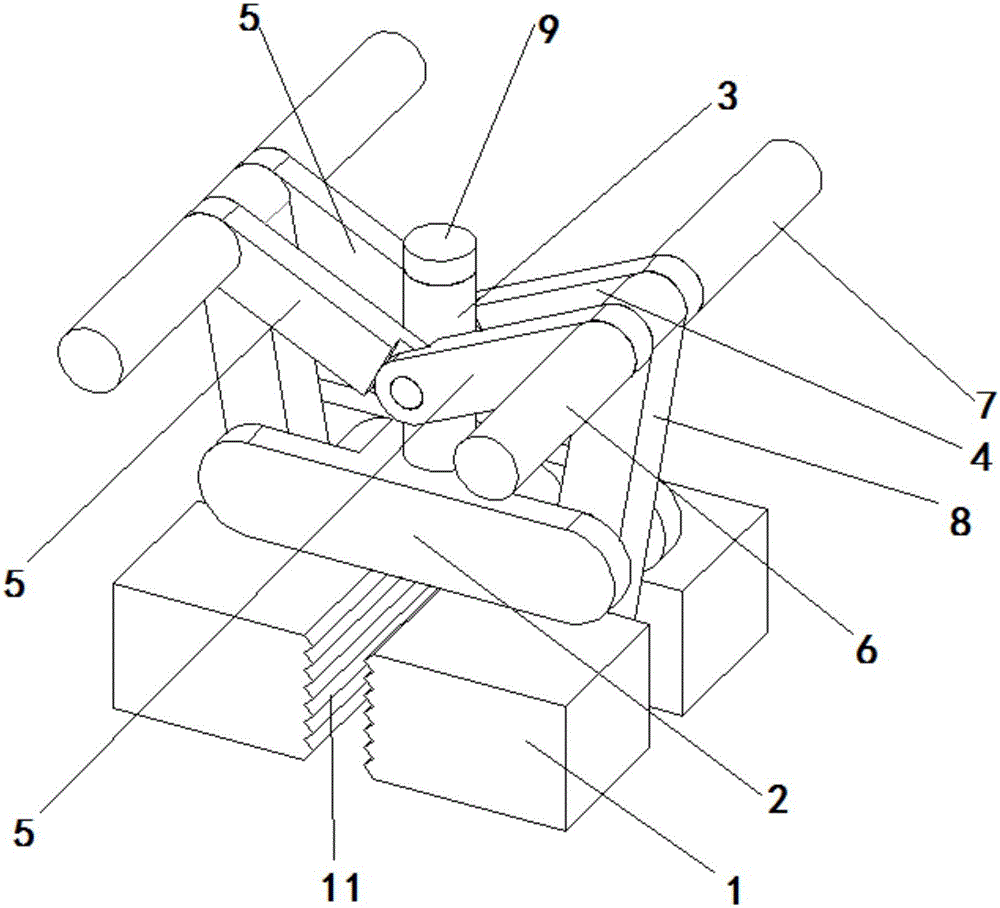

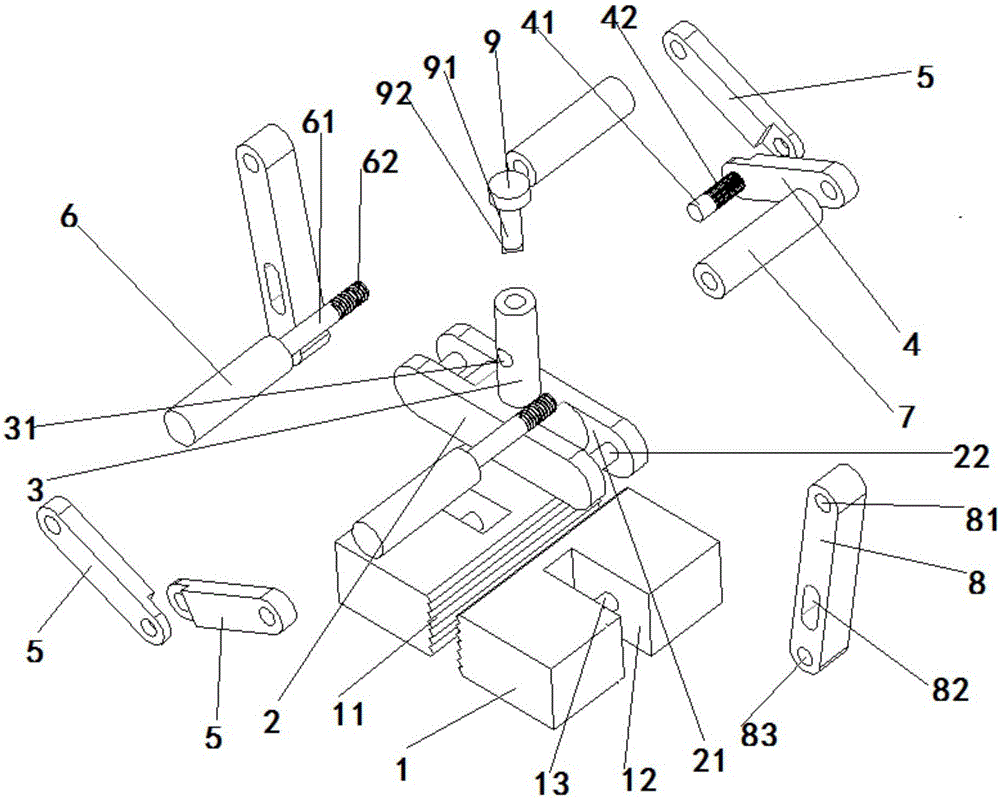

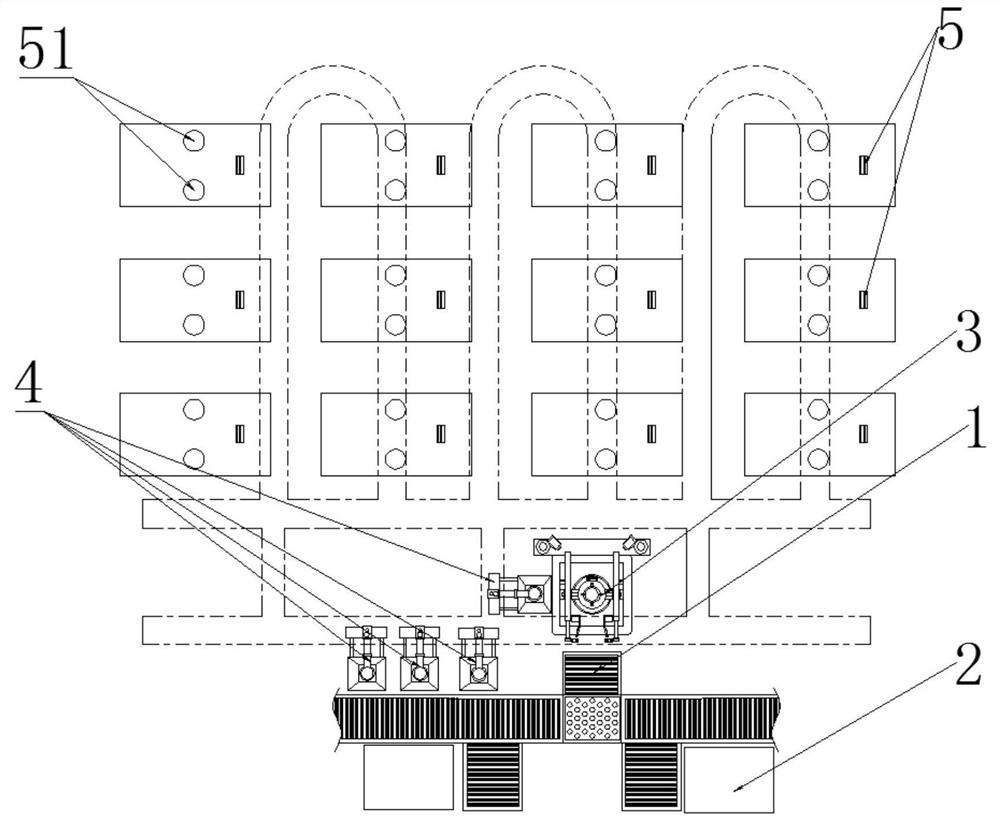

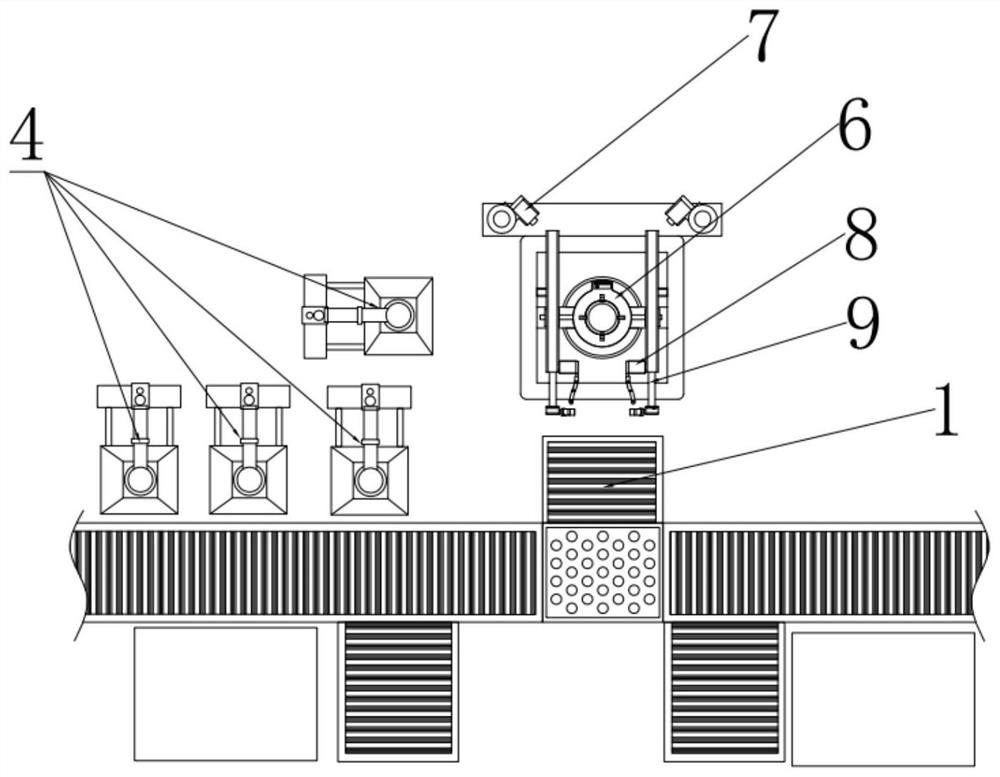

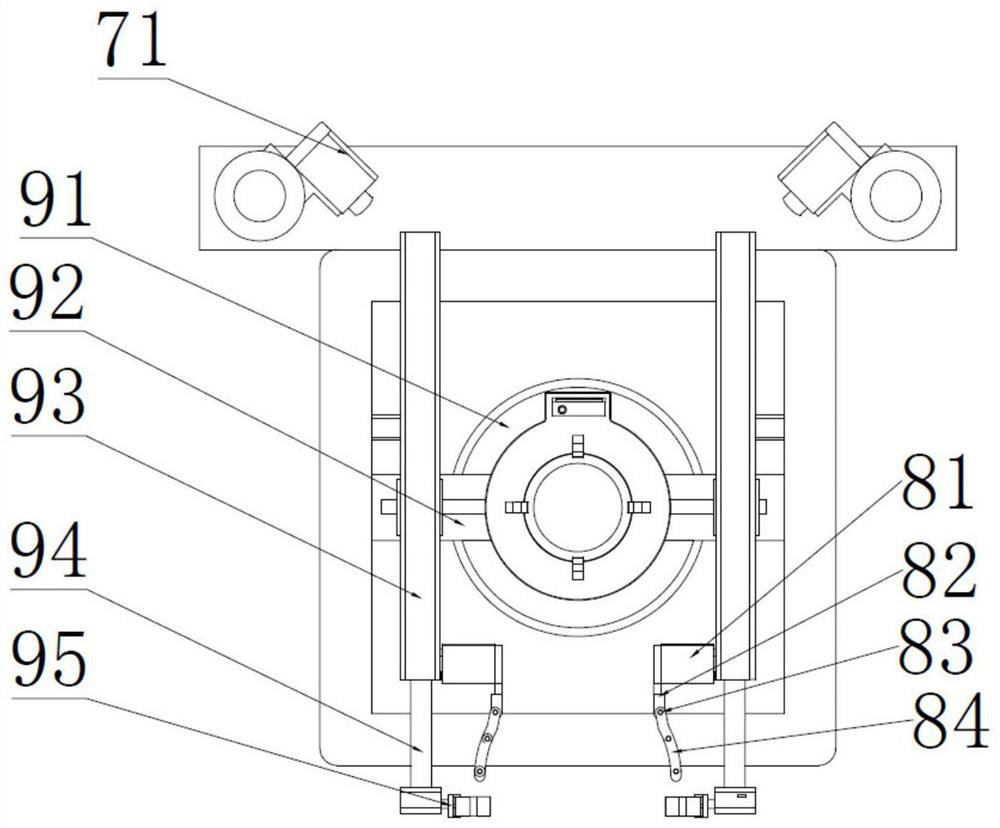

Intelligent clamp fast-replacement device

InactiveCN105269201AQuick releaseQuick clampingWelding/cutting auxillary devicesAuxillary welding devicesForcepsEngineering

The invention relates to an intelligent clamp fast-replacement device. The intelligent clamp fast-replacement device comprises a clamp top plate and a clamp bottom plate; a welding air cylinder and a welding head located on the welding air cylinder are arranged on the clamp top plate and between the clamp top plate and the clamp bottom plate; a workpiece clamping structure is arranged on the clamp bottom plate and between the clamp top plate and the clamp bottom plate; a fast clamp forceps structure is disposed on the clamp top plate; a fast inserting structure is disposed on the clamp bottom plate. By means of the structure, the clamp structure can be fast dismantled and mounted for clamping; fast error correction can be achieved through a workpiece detector and a nut detector; operation is convenient; defective products are reduced; time is saved; the working efficiency of a welding machine is improved; the ex-factory cost of products is reduced.

Owner:阮明鑫

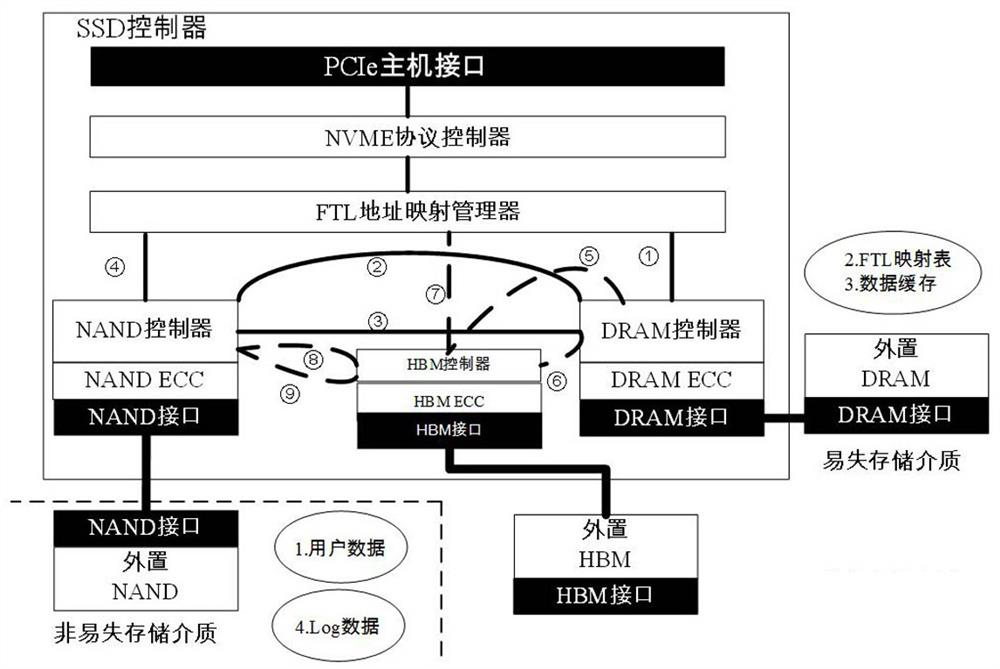

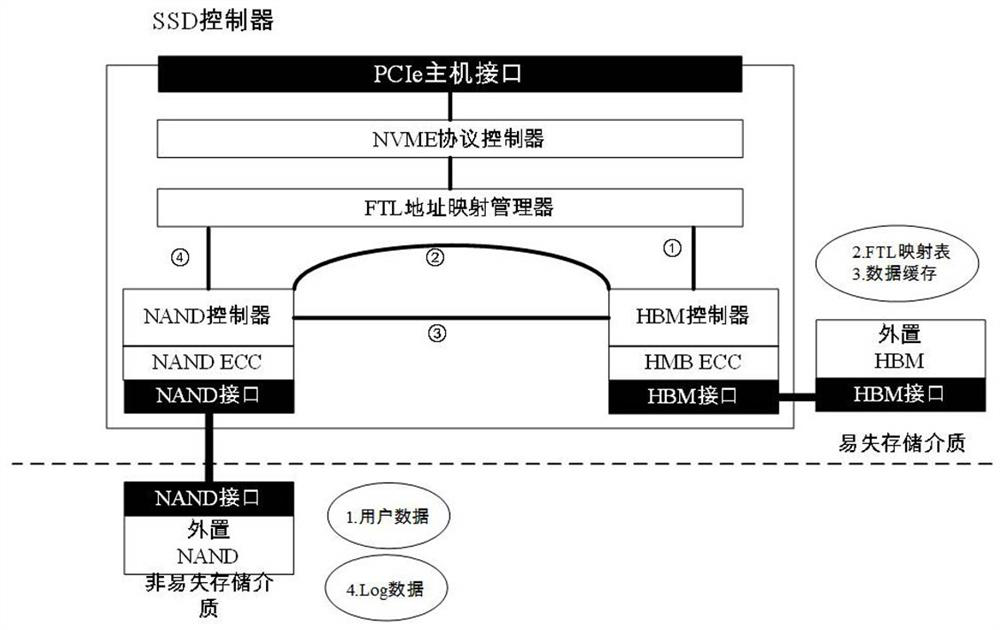

SSD based on HBM cache

PendingCN113760796AReduce visit frequencyReduce interruptionsMemory adressing/allocation/relocationEnergy efficient computingWrite amplificationComputer architecture

The invention relates to an SSD based on an HBM cache, and the SSD comprises an SSD based on the HBM and DRAM hybrid cache and an SSD based on the HBM cache; the SSD based on the HBM and DRAM hybrid cache mixedly uses the HBM and the DRAM as the cache, the DRAM stores an FTL (File Transfer Layer) mapping table, and the HBM provides a cache function. According to the SSD based on the HBM cache, the HBM is used for replacing a DRAM, and the HBM has the functions of caching data and storing an FTL mapping table. According to the method, the constant read-write bandwidth is ensured in the process of processing write amplification and garbage collection, the read-write time delay is reduced, and the high-concurrency multi-channel video data access efficiency is ensured to a greater extent.

Owner:SHANDONG SINOCHIP SEMICON

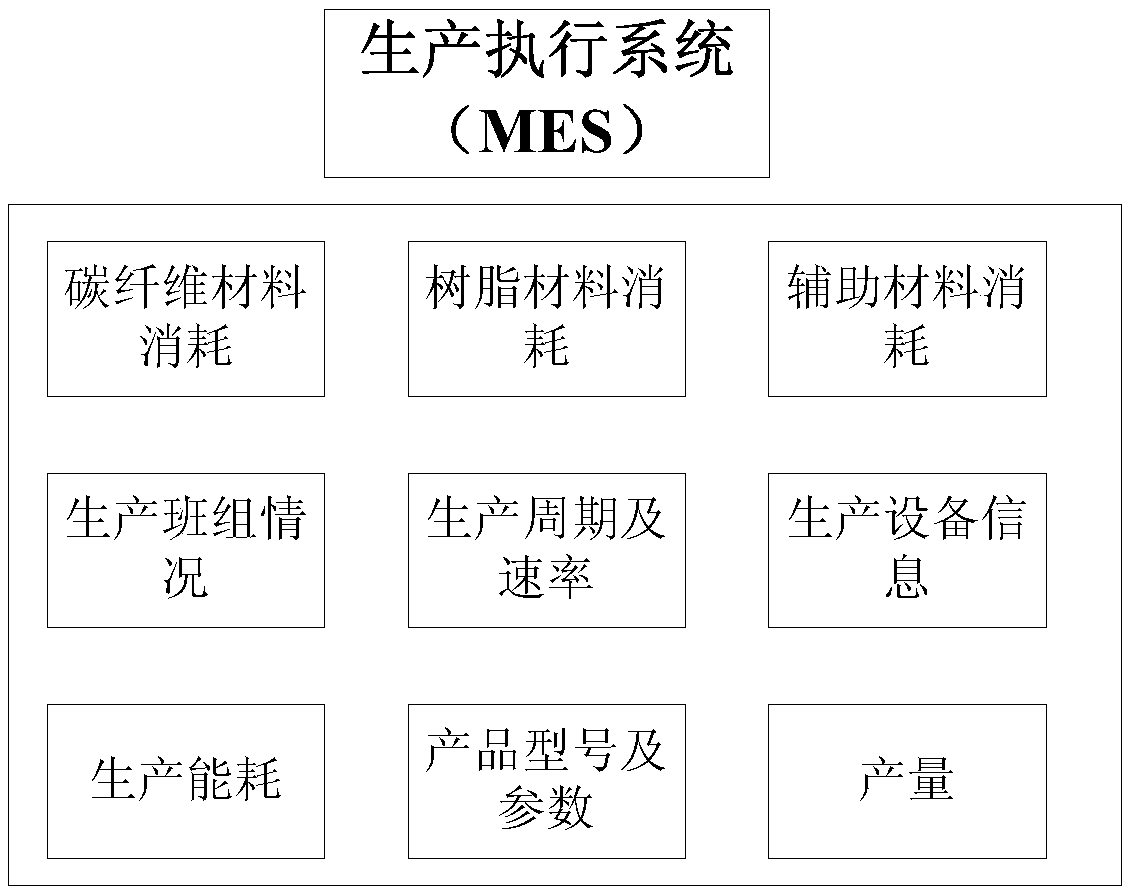

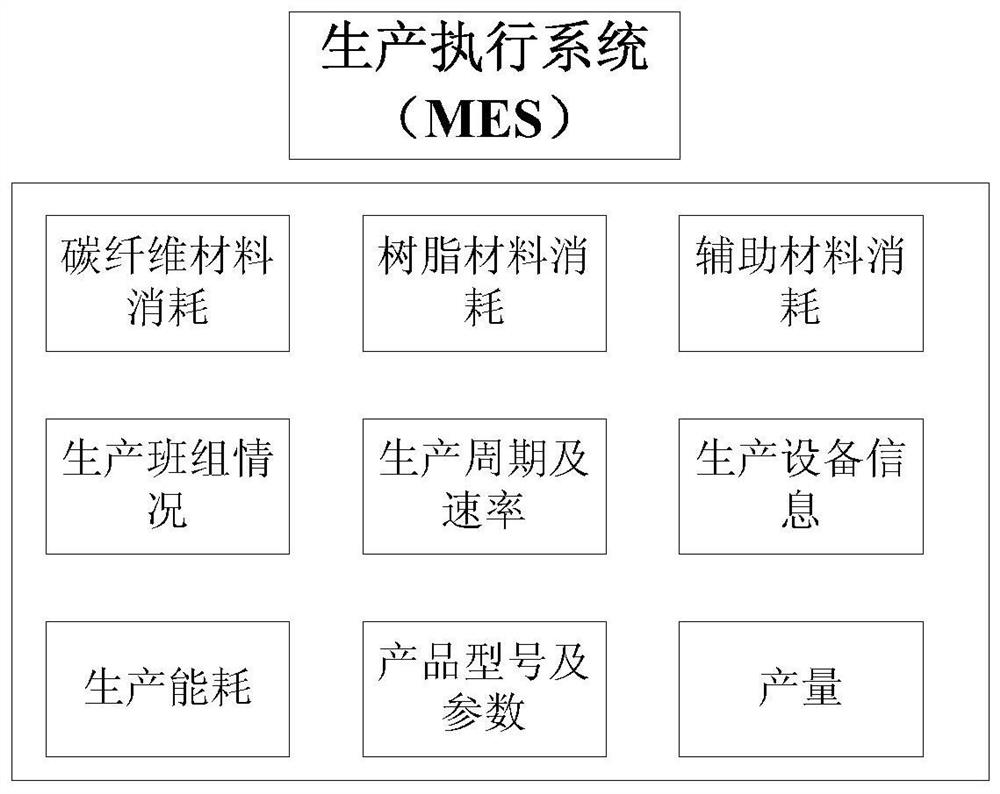

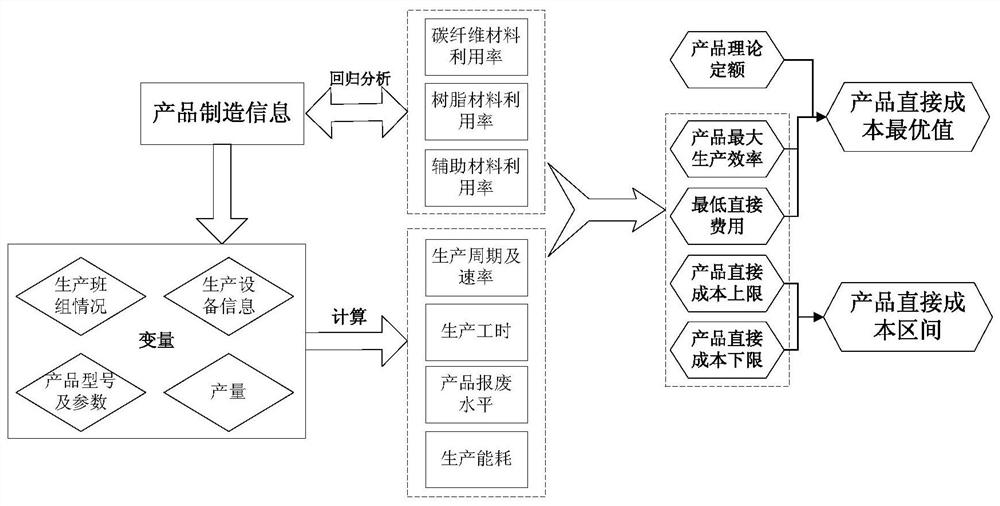

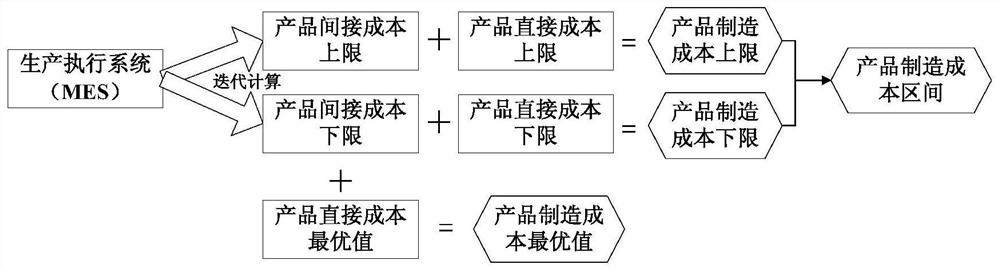

Cost calculation and monitoring system based on prepregs in technological manufacturing process

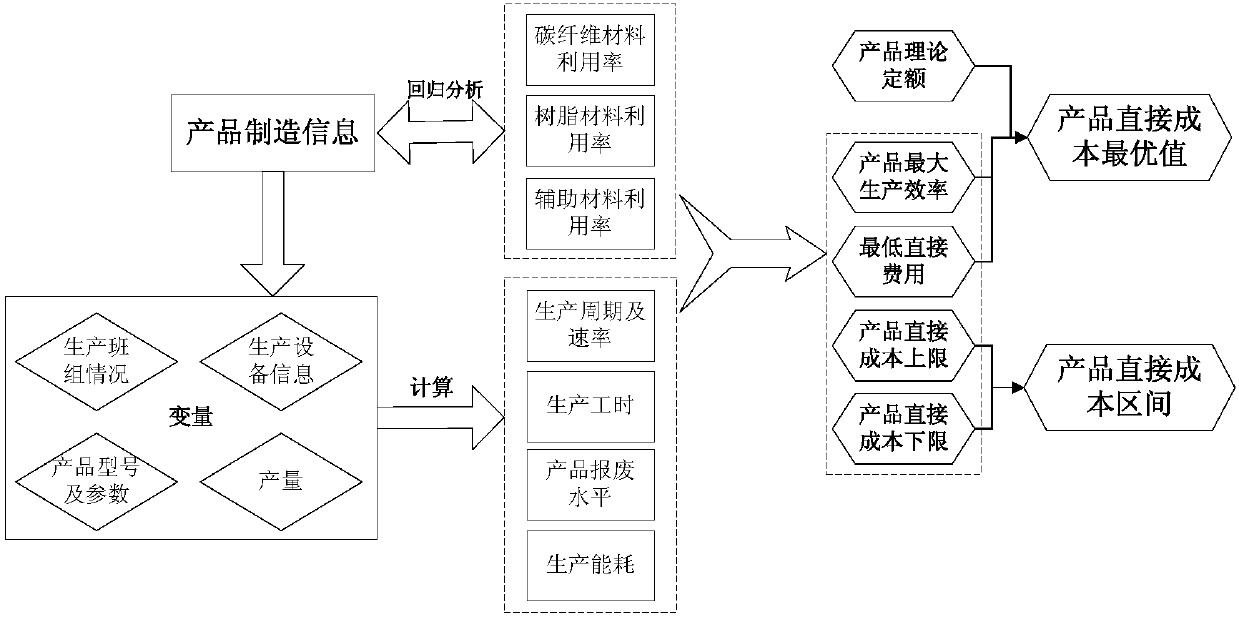

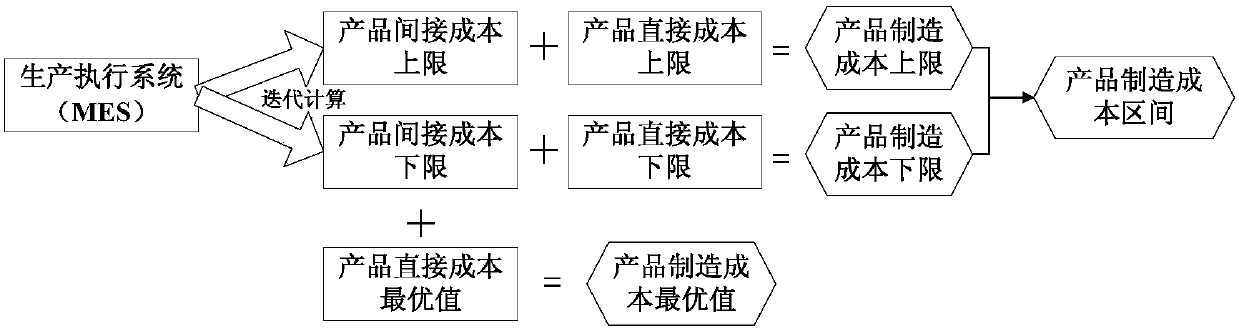

The invention belongs to the technical field of composite material manufacturing, and relates to a cost calculation and control system in a high molecular material preparation process, in particular to a cost calculation and monitoring system based on prepregs in a technological manufacturing process. According to a given prepreg cost calculation mode, a mode of including manufacturing direct expense allocation of direct labor, equipment depreciation, manufacturing power consumption and the like in product manufacturing cost in conventional product cost calculation is abandoned; and based on an actual manufacturing process and a manufacturing status, a manufacturing execution system (MES) is adopted for collecting fiber material consumption, resin material consumption, auxiliary material consumption, manufacturing team or group states, manufacturing cycle and speed, manufacturing equipment information, manufacturing energy consumption, product types and parameters, yield and rejectionrate data information, and expenses directly related to manufacturing in manufacturing expenses are stripped out to the maximum extent, so that accurate calculation of the product manufacturing cost is realized and the manufacturing cost fluctuation states of products in different manufacturing conditions can be accurately reflected.

Owner:AVIC COMPOSITES

Manual welding and clamping device

InactiveCN106378565AReduce generationImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses a manual welding and clamping device which comprises a base. Installing grooves are symmetrically formed in the two ends of the base. A rotating shaft is arranged in each installing groove. A fixed cylinder is fixed right above the base. A locating hole is horizontally formed in the middle of the fixed cylinder. A top cover is installed on the upper portion of the fixed cylinder. A locating shaft is arranged below the top cover. A limiting piece is arranged at the bottom end of the locating shaft. A main rotating plate is installed on the front side of the fixed cylinder. An installing shaft is arranged at one end of the inner side of the main rotating plate. A tooth groove surrounding the installing shaft by one circle is formed in the middle of the installing shaft. The installing shaft is installed in the locating hole. Two auxiliary rotating plates with the structure the same as that of the main rotating plate are hinged to the tail end of the installing shaft, wherein the two auxiliary rotating plates are arranged symmetrically. Auxiliary rotating plates are symmetrically arranged on the outer side of the main rotating plate. The manual welding and clamping device can achieve fast disassembling and clamping, fast error correction can be achieved through a workpiece detector and a nut detector, operation is convenient, generation of inferior-quality products is reduced, time is saved, the working efficiency of a welding machine is improved, and the ex-factory cost of the products is reduced.

Owner:周峰

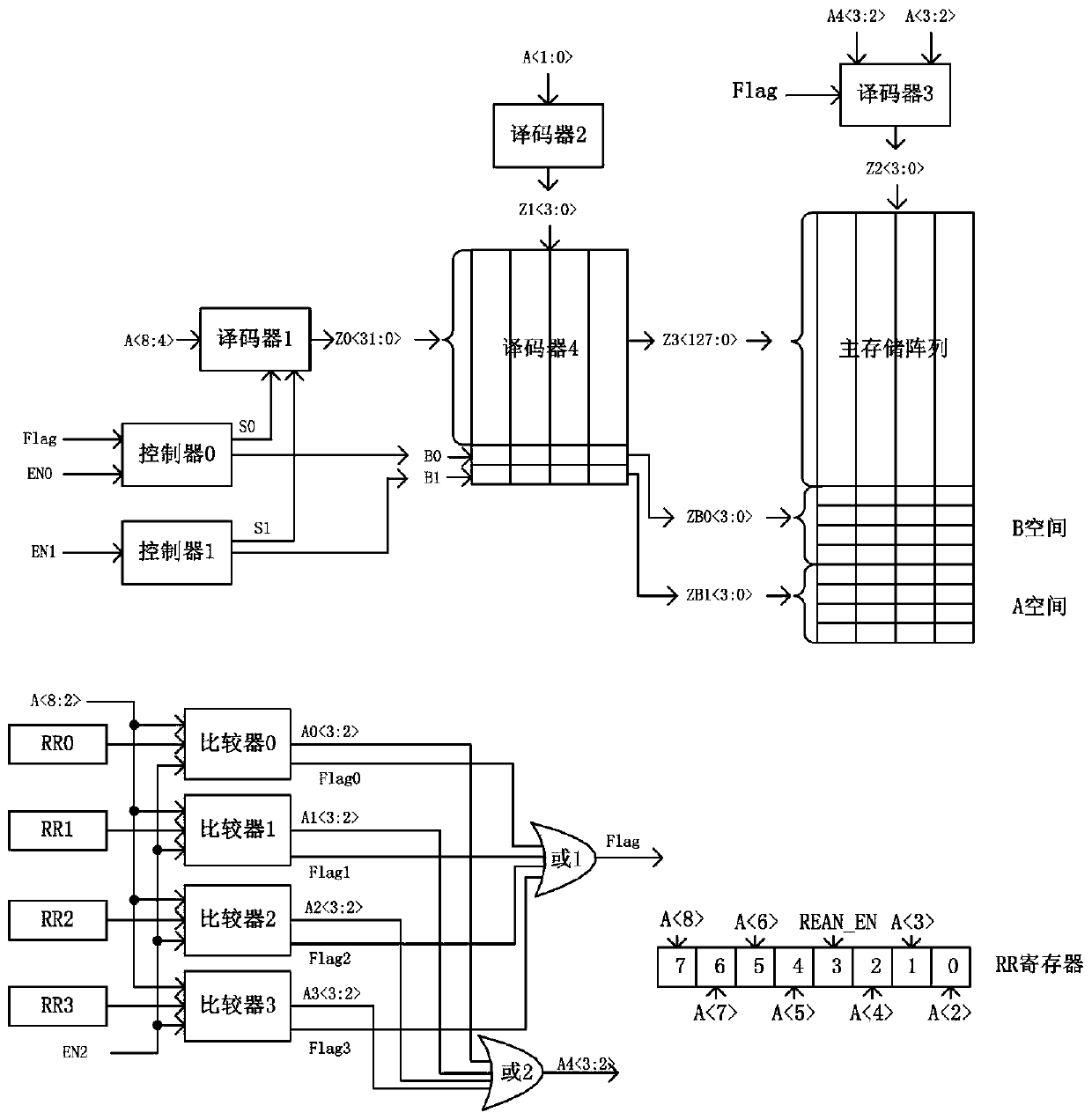

Redundancy error correction structure of OTP

ActiveCN111383701AReduce wasteAdd redundant storage spaceStatic storageEnergy efficient computingComputer hardwareData class

The invention discloses a redundancy error correction structure of an OTP. The redundancy error correction structure comprises a redundancy storage array, an address decoding module and a logic control module. The redundant storage array is divided into a space A for storing addresses of damaged storage units and a space B for replacing the damaged storage units; the address decoding module is used for decoding an input address A (8: 0); and the logic control module is used for comparing the input address with the address of the damaged storage unit stored in the space A, and generating a control signal to control the memory reading operation under the condition that the damaged storage unit occurs in the main storage array. According to the redundancy error correction structure, due to the fact that the error rate of the storage array is low and the redundancy storage space is increased in a targeted mode, waste of the chip area is greatly reduced; damaged storage units are directly replaced, logic judgment is not needed, and errors of all storage data types can be corrected; redundancy error correction is achieved through a register, the error correction speed is high, and efficiency is high.

Owner:58TH RES INST OF CETC

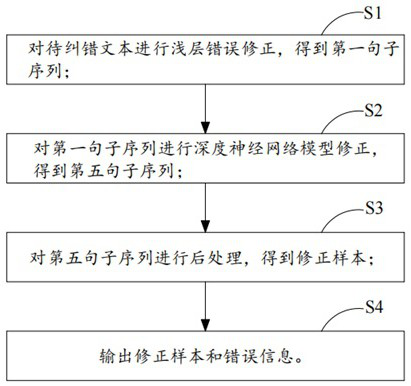

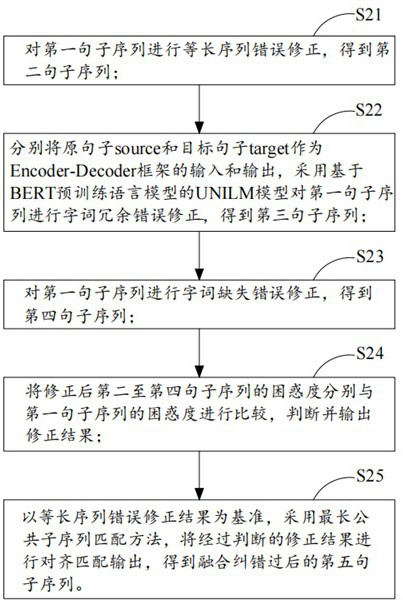

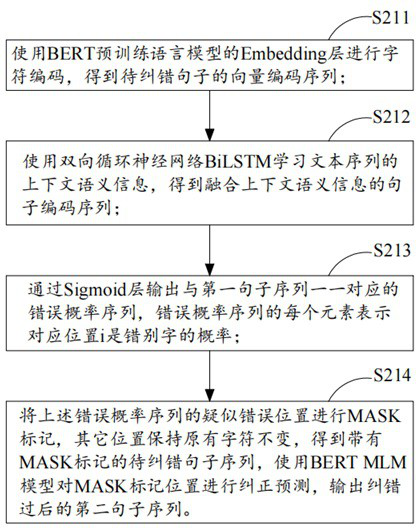

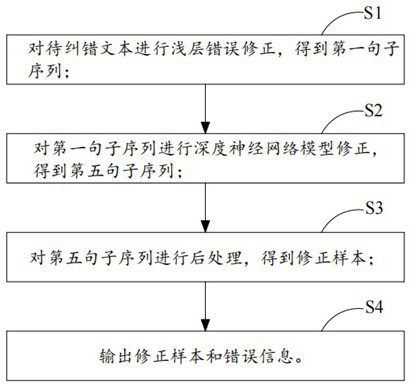

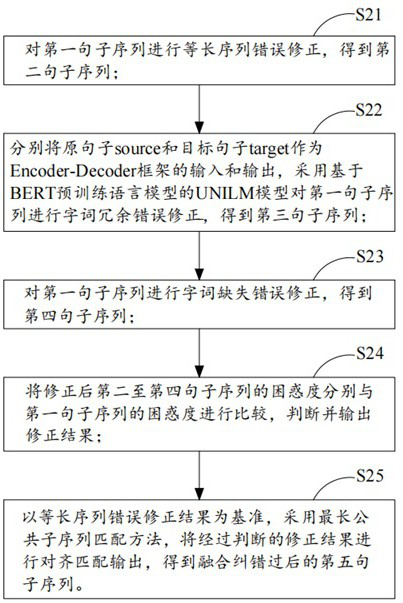

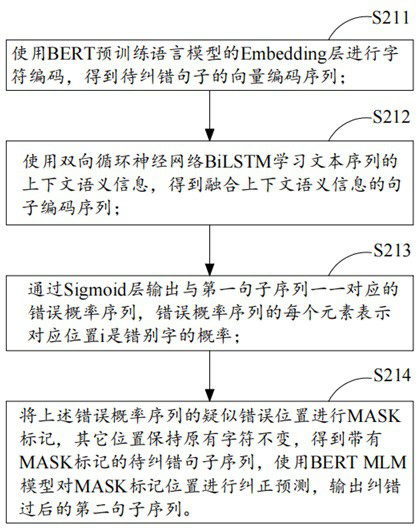

Chinese text automatic error correction method and device

ActiveCN114372441ARealize automatic generationQuick buildSemantic analysisNeural architecturesData setAlgorithm

The invention provides a Chinese text automatic error correction method and device, and the method comprises the steps: carrying out the shallow error correction of a to-be-corrected text, and obtaining a first sentence sequence; performing deep neural network model correction on the first sentence sequence to obtain a fifth sentence sequence; post-processing the fifth sentence sequence to obtain a corrected sample; and outputting the correction sample and the error information. The device provided by the invention comprises a shallow error correction module, a deep neural network model correction module, a post-processing module and an integrated output module, the deep neural network model correction module is composed of an equal-length sequence error correction unit, a word redundancy error correction unit, a word missing error correction unit, a language model judgment unit and a three-model fusion unit, and the post-processing module is composed of a place name error detection unit and a sensitive word error detection unit. According to the method, automatic data set generation and deep neural network model correction can be realized, the Chinese error correction range is more comprehensive, and the error correction efficiency is higher.

Owner:中电云计算技术有限公司

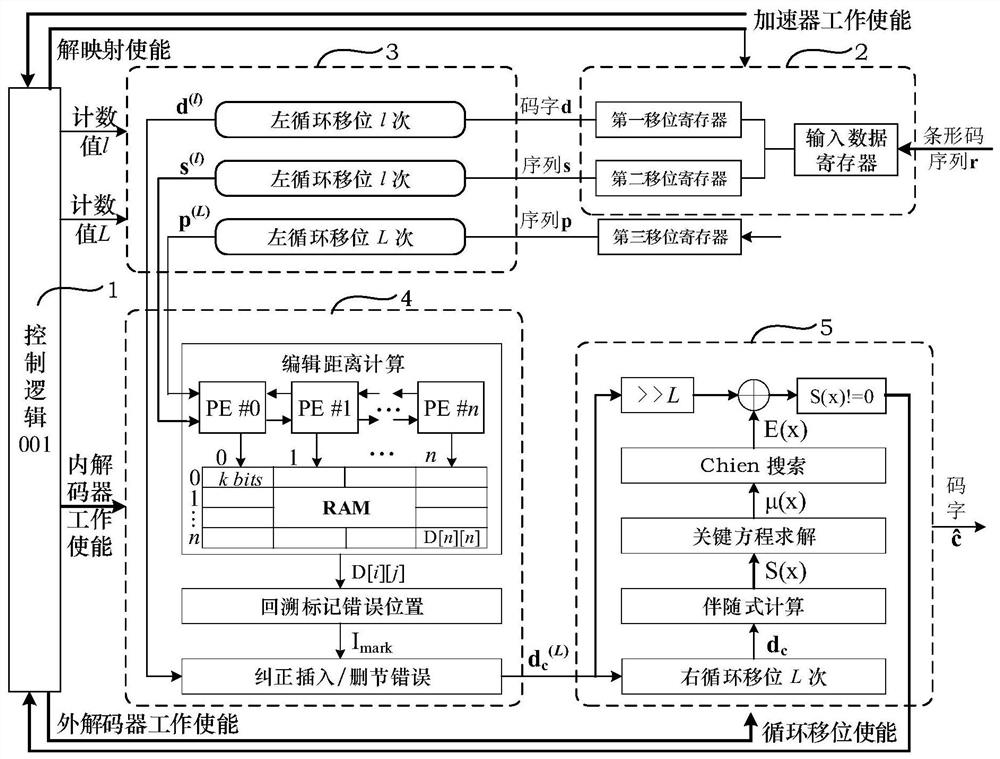

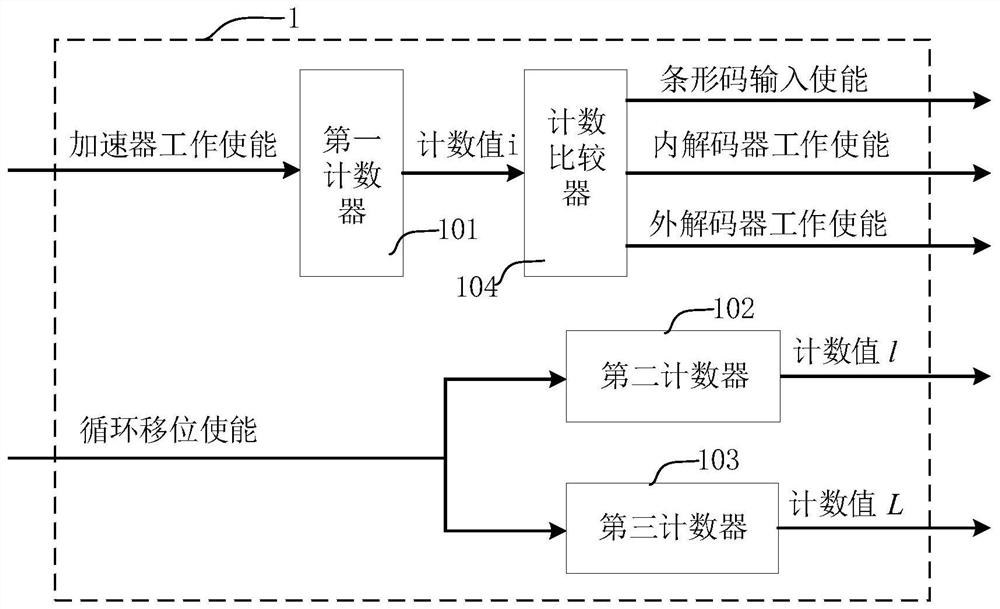

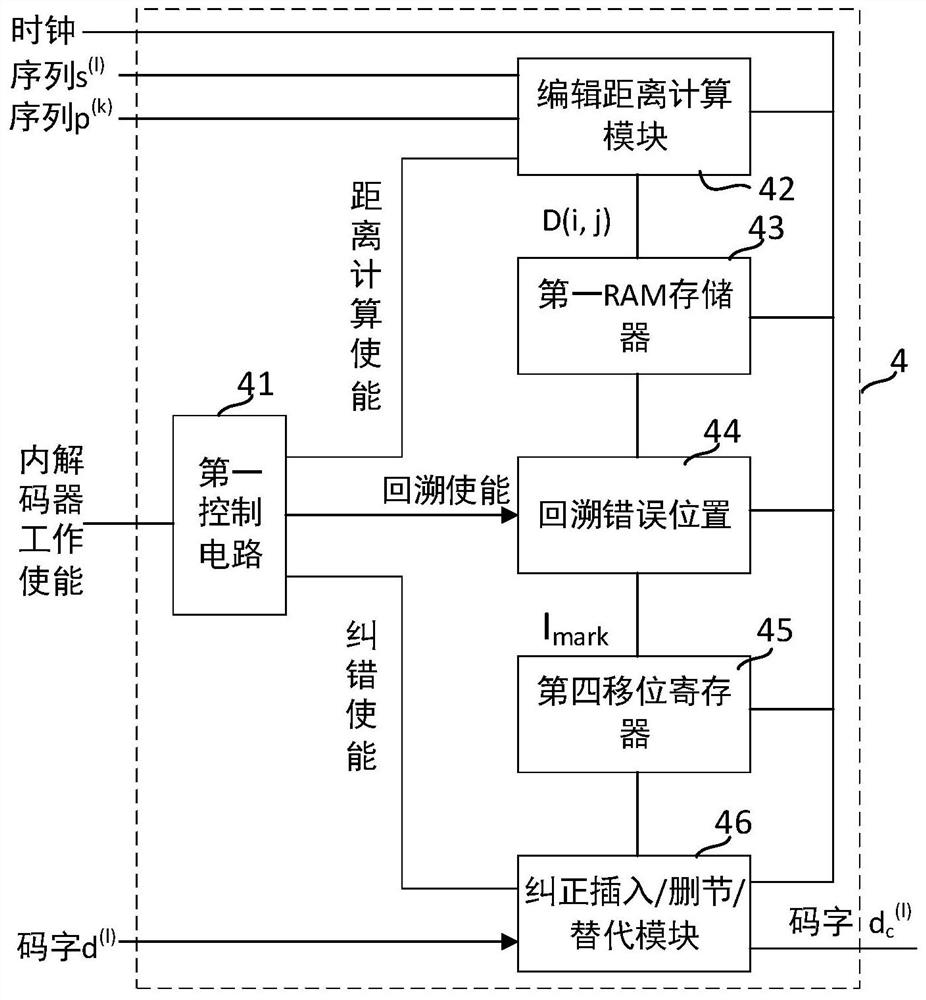

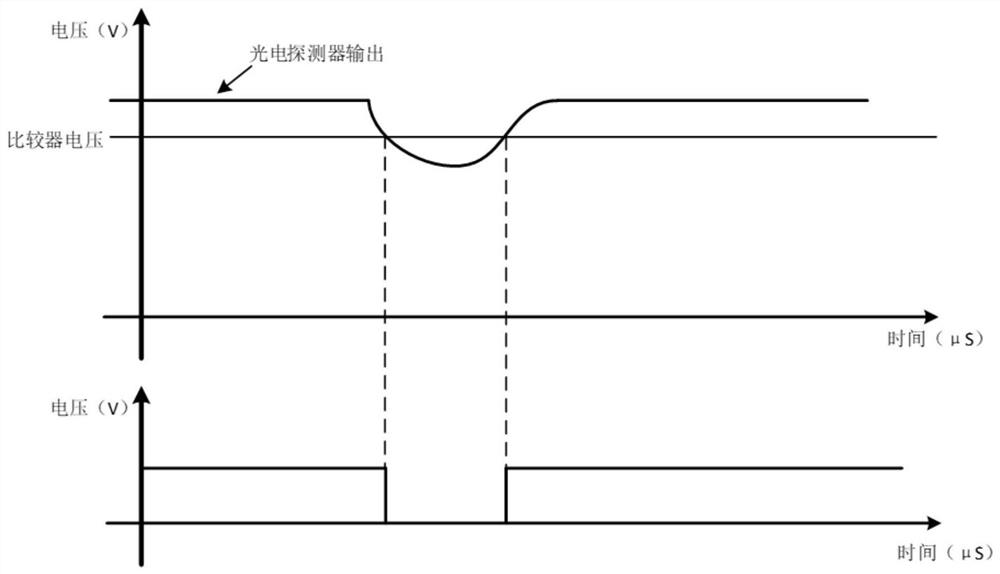

Hardware acceleration device of bar code recognition algorithm for DNA sequencing

ActiveCN113343736AFast error correctionReduce time complexityEnergy efficient computingSensing by electromagnetic radiationBarcodeRecognition algorithm

The invention discloses a hardware acceleration device of a bar code recognition algorithm for DNA sequencing, which comprises a control logic unit, a demapping unit, a cyclic shift unit, an inner decoder and an outer decoder, the control logic unit is respectively connected with the demapping unit, the cyclic shift unit, the inner decoder and the outer decoder, the demapping unit is connected with the cyclic shift unit, and the inner decoder is connected with the outer decoder; and the device has the advantages that the time complexity is reduced, the time for distinguishing the sequencing reads from different samples is shortened, and various errors of the sequencing bar codes are quickly corrected.

Owner:THE ACAD OF TIANJIN UNIV HEFEI

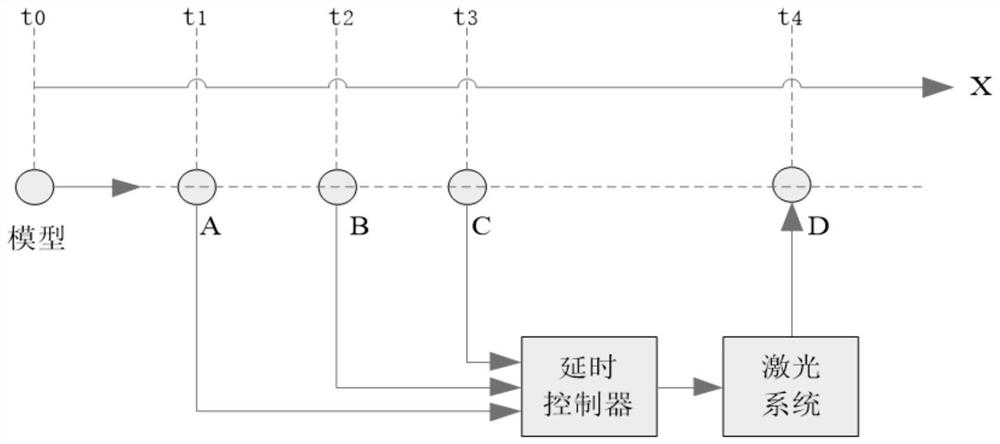

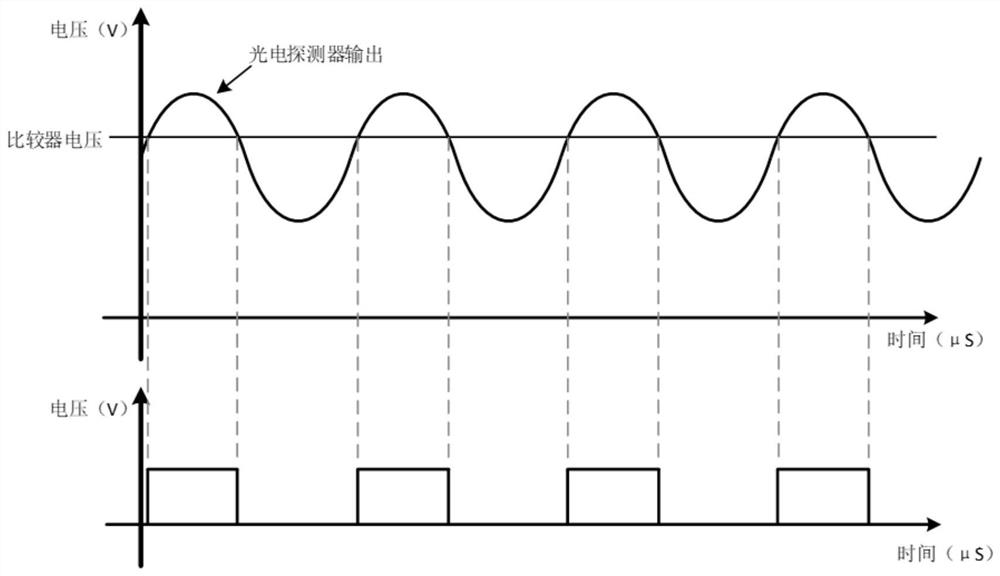

Testing device for gas-detonation-driven ultra-high-speed emission

The invention discloses a testing device for gas-detonation-driven ultra-high-speed emission. The testing device for gas-detonation-driven ultra-high-speed emission comprises a model and a target chamber measuring section at a position a certain distance away from the model, wherein four observation windows A, B, C and D are sequentially formed in the target chamber measuring section at certain intervals separately; the window A, the window B and the window C are connected with a delay controller separately; a laser system and a camera are arranged at the position of the window D; a projectilepasses through the window A, the window B and the window C of a detection point in sequence, a flight speed is calculated by calculating the flight time between the adjacent detection windows, then the time needing to be delayed is calculated, the delay controller outputs the delay time to control the laser system to flash, and a schlieren image of the projectile passing through the window D is captured through the camera. Higher stability is achieved; higher sensitivity is achieved, and a non-triggering phenomenon is avoided; experimental data is richer, and analysis of experimenters is facilitated; and the time can be corrected manually and accurately.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

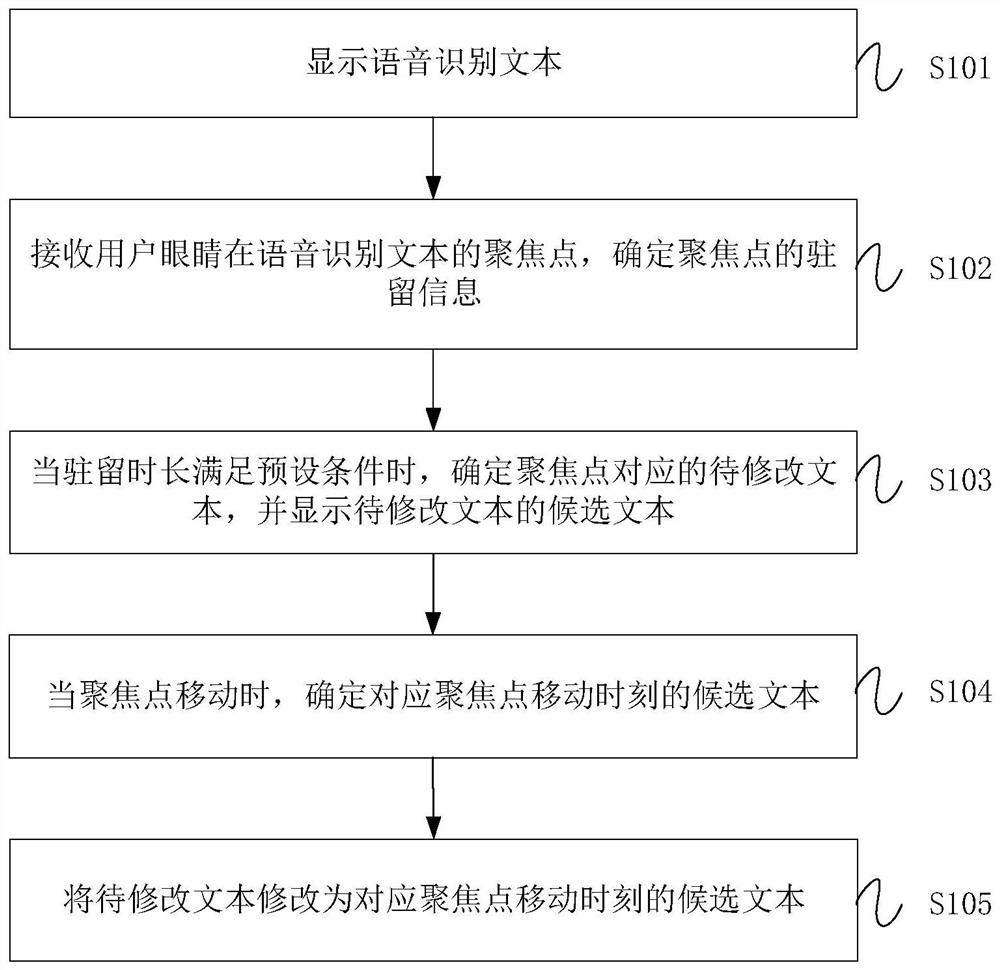

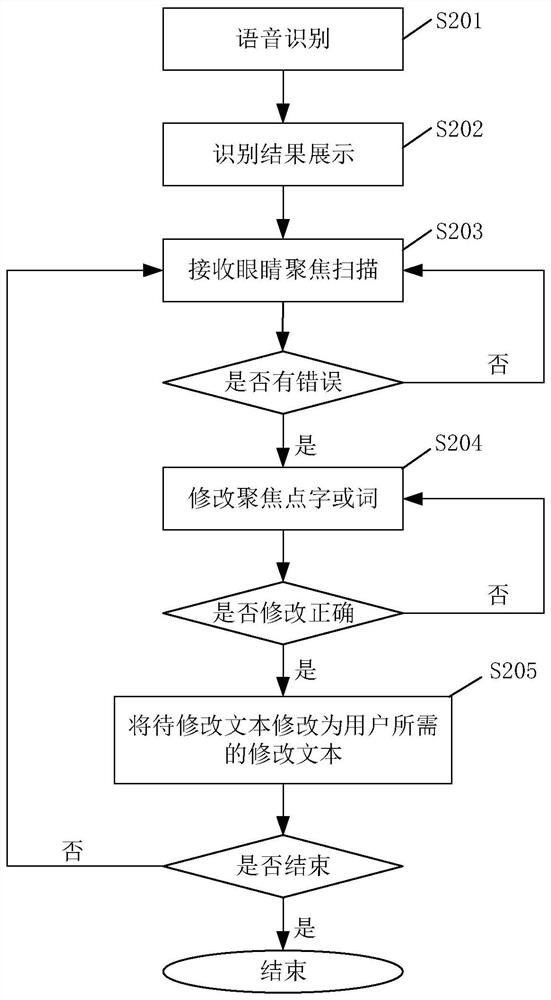

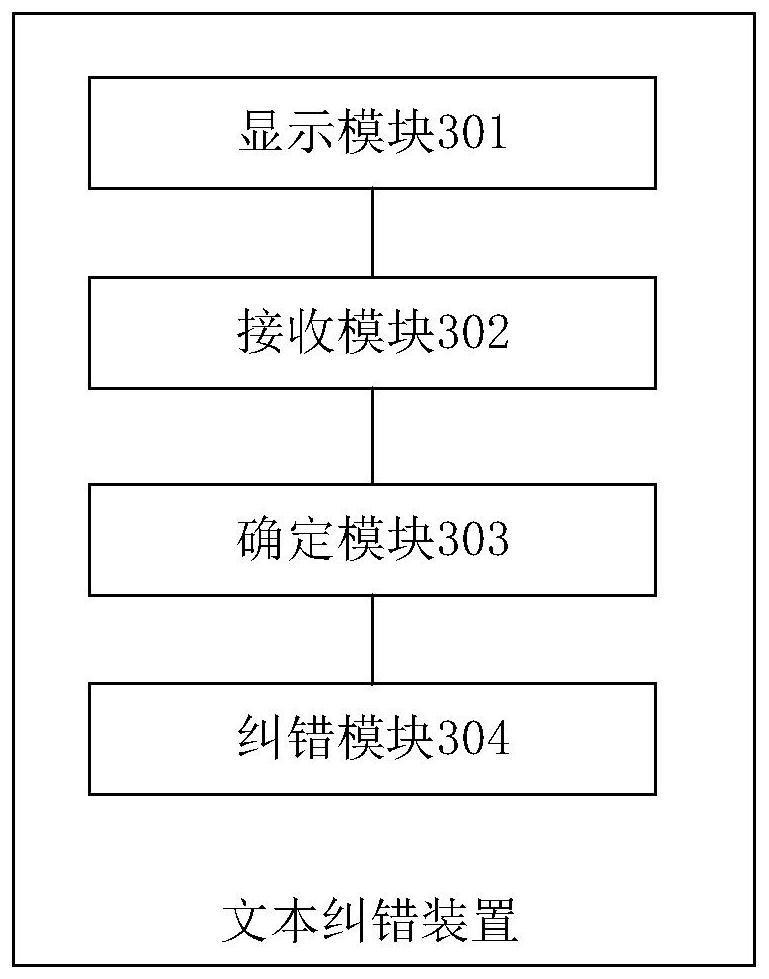

Text error correction method, device and equipment and computer readable storage medium

ActiveCN113448430ASolve the pain points that require manual input due to multiple error correction requirementsReduce manual operationsInput/output for user-computer interactionSpeech recognitionUser inputEngineering

The embodiment of the invention provides a text error correction method, device and equipment and a computer readable storage medium. The text error correction method comprises the following steps: displaying a speech recognition text; receiving a focus point of the eyes of the user in the speech recognition text, and determining residence information of the focus point, the residence information including residence time; when the residence duration meets a preset condition, determining a to-be-modified text corresponding to the focus point, and displaying candidate texts of the to-be-modified text; when the focus point moves, determining a candidate text corresponding to the focus point moving moment; and modifying the to-be-modified text into a candidate text corresponding to the focus point moving moment. According to the embodiment of the invention, the error recognition of the text can be conveniently and quickly corrected without user input, and the text error can be quickly and accurately corrected.

Owner:CHINA MOBILE CHENGDU INFORMATION & TELECOMM TECH CO LTD +1

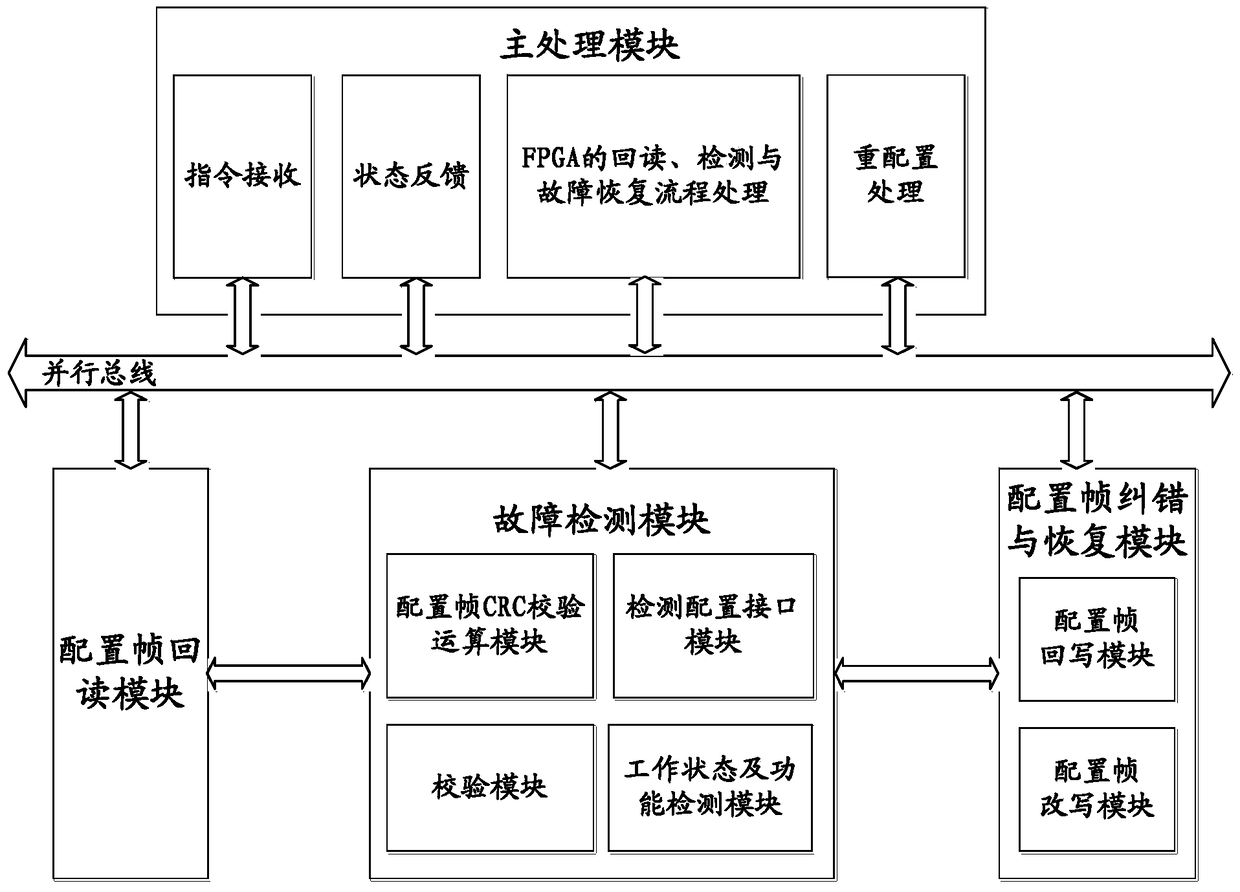

A fault detection and repair method for on-orbit sram type fpga based on configuration frame

ActiveCN104579313BEasy to detectAchieve fixLogic circuits using elementary logic circuit componentsSpace environmentReliability design

The invention relates to an on-rail SRAM type FPGA fault detection and repair method based on a configuration frame, which is realized by a fault detection and repair system. The fault detection and repair system includes a main processing module, a configuration frame readback module, a fault detection module and a configuration frame Error correction and recovery module, the present invention implements frame-by-frame readback, verification and writeback or rewrite of the internal configuration information of SRAM FPGA through the fault detection and repair system implemented on the highly reliable chip, and realizes configuration information frame The level of fault detection and repair greatly improves the detection rate and repair ability of the configuration information flip problem caused by the single event effect of the space environment. A general reliability design approach supported by software.

Owner:BEIJING INST OF CONTROL ENG

A Chinese text automatic error correction method and device

ActiveCN114372441BRealize automatic generationQuick buildSemantic analysisNeural architecturesData setAlgorithm

Owner:中电云计算技术有限公司

Method and system for encrypted retrieval of verifiable database based on secret sharing

ActiveCN108763940BQuick and easy error correctionQuick checkKey distribution for secure communicationDigital data protectionChinese remainder theoremData access

The invention discloses a verifiable database encrypted retrieval method based on secret sharing, which comprises the following steps: establishing a database; storing data to be encrypted into the database, and encrypting by secret sharing; formulating a data visitor authority form, and determining the data visitor authority , through the processing of the Chinese remainder theorem, the data accessor authority table is stored in the database; the encrypted data is moduloed, and the check code corresponding to each column attribute is generated and uploaded to the server; the data visitor accesses the server and has authority data access Those who have no authority can solve the data, and those without authority cannot solve the data; the present invention combines secret sharing and the Chinese remainder theorem, and uses the remainder of each data modulo the assigned value as a check code, without reconstructing f(x) On the Internet, the information on the server is checked independently; when some information is wrong, it can also be combined with other servers to point out which server is wrong, and quickly and easily correct the wrong information.

Owner:SOUTH CHINA AGRI UNIV

Error correction method for automatic recognition of license plate number by traffic capture

ActiveCN105118300BFast error correctionImprove accuracyRoad vehicles traffic controlCharacter and pattern recognitionIn vehicleForward error correction

The invention discloses a method of correcting a license plate number automatically recognized in traffic snapshot. The method comprises steps: 1, error detection is carried out: license plate numbers in vehicle passing records are matched with the existing already-issued license plate numbers; and if a certain license plate number succeeds in matching in the above step, whether the license plate number is correctly recognized is verified next; and 2, error correction is carried out: through carrying out the above error detection on the license plate numbers, a large number of wrongly-recognized license plate numbers are obtained, and the error correction process is to correct the wrongly-recognized license plate numbers to be actually true license plate numbers of vehicles.

Owner:广东启功实业集团有限公司

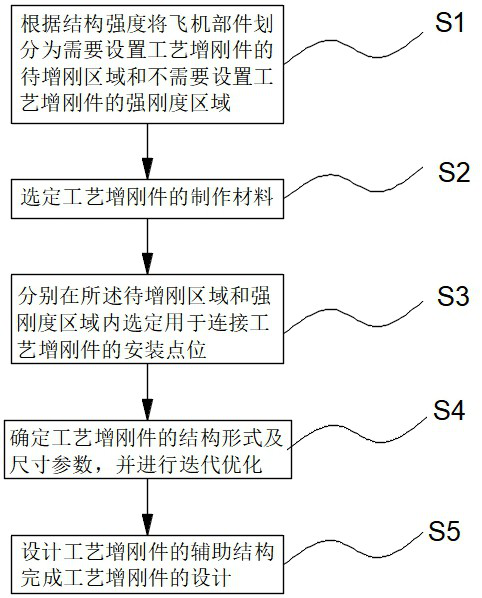

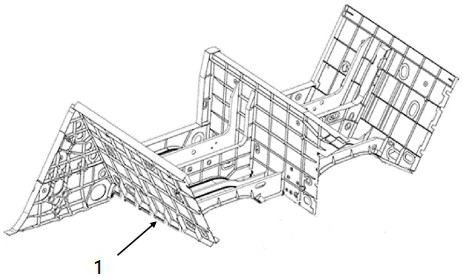

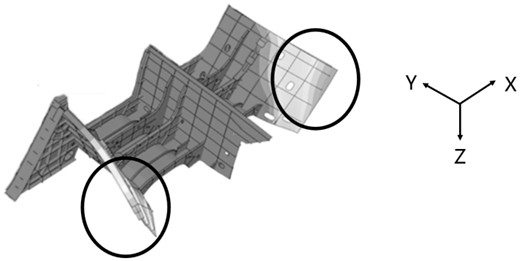

A Design Method for Technological Rigid Parts Used in Aircraft Parts

ActiveCN113636098BFast error correctionImprove error correctionGround installationsProcess engineeringUltimate tensile strength

The invention discloses a method for designing process stiffening parts for aircraft parts, including the delineation of the area to be stiffened, the determination of the installation point of the process stiffening parts, the material selection of the process stiffening parts, the design of process parameters and the process of stiffening The optimization iteration of parts; the invention standardizes the design process of process stiffening parts, so that technicians can quickly and accurately complete the design of process stiffening parts, and the standardized design process can not only effectively avoid design blind spots, but also has a strong Traceability, when an error occurs, the cause of the error can be quickly and accurately locked, which improves work efficiency and design quality; at the same time, the process stiffening part is connected to the area to be stiffened and the area with high rigidity, effectively ensuring that the process stiffening part is always consistent with the same The rooting point whose strength is higher than that of the area to be stiffened is stably connected to ensure the effective stiffening of the area to be stiffened, avoiding the slipping or even collapse of the process stiffened part under the action of external force, which will cause the stiffness to fail, and improve the stability of the process stiffened part sex and reliability.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

A Cost Calculation and Monitoring System of Prepreg Based on Process Manufacturing

The invention belongs to the technical field of composite material manufacturing, and relates to a cost calculation and control system in a high molecular material preparation process, in particular to a cost calculation and monitoring system based on prepregs in a technological manufacturing process. According to a given prepreg cost calculation mode, a mode of including manufacturing direct expense allocation of direct labor, equipment depreciation, manufacturing power consumption and the like in product manufacturing cost in conventional product cost calculation is abandoned; and based on an actual manufacturing process and a manufacturing status, a manufacturing execution system (MES) is adopted for collecting fiber material consumption, resin material consumption, auxiliary material consumption, manufacturing team or group states, manufacturing cycle and speed, manufacturing equipment information, manufacturing energy consumption, product types and parameters, yield and rejectionrate data information, and expenses directly related to manufacturing in manufacturing expenses are stripped out to the maximum extent, so that accurate calculation of the product manufacturing cost is realized and the manufacturing cost fluctuation states of products in different manufacturing conditions can be accurately reflected.

Owner:AVIC COMPOSITES

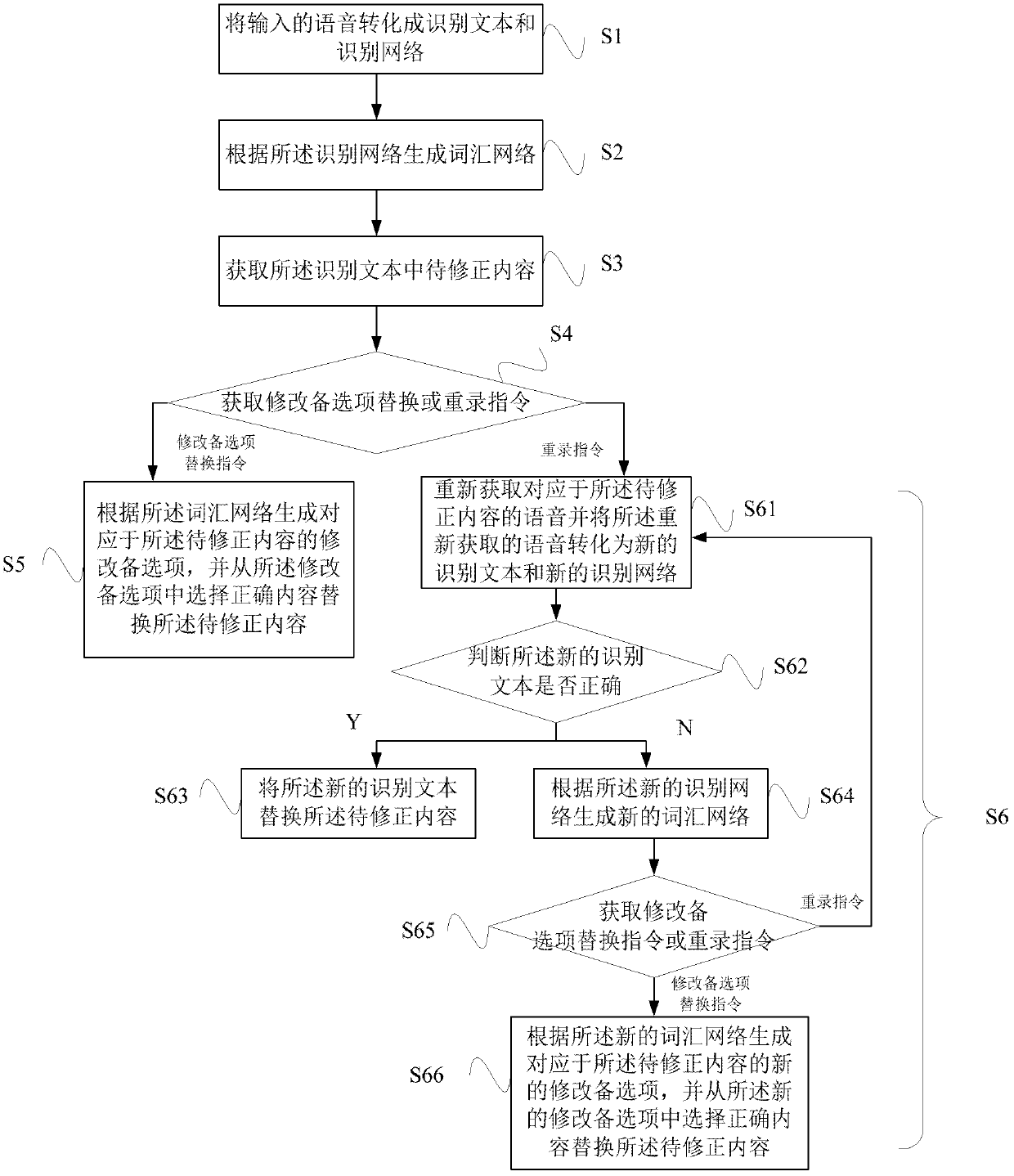

Speech input error correction method and system

ActiveCN103366741BHigh recognition reliabilityFast error correctionSpeech recognitionSound input/outputComputer hardwareCorrection method

The invention relates to a voice input error correction method and system. The method includes converting an input voice into an identification text and an identification network; generating a lexical network according to the identification network; acquiring contents waiting to be corrected in the identification text; acquiring a modification-alternative replacement or rerecording instruction; if it is a modification-alternative replacement instruction, then generating a modification alternative corresponding to the contents waiting to be corrected according to the lexical network and selecting correct contents from the modification alternative to replace the contents waiting to be corrected; and if it is a rerecording instruction, then reacquiring a voice corresponding to the contents waiting to be corrected and correcting the contents waiting to be corrected. In the voice input error correction method and system, the modification alternative can be provided to modify error parts of the identification text and the error parts of the identification text can also be modified through rerecording part of the voice.

Owner:SHANGHAI GUOKE ELECTRONICS

AR intelligent ordering and delivering system

InactiveCN113516567AJudging the portion sizeImprove satisfactionProgramme-controlled manipulatorData processing applicationsComputer hardwareEmbedded system

The invention discloses an AR intelligent ordering and delivering system, and the system comprises a server, an AR ordering machine, a delivering robot, a chef communication module, a meal outlet and a conveying device; the conveying device is connected with a chef station and the meal outlet, and the AR ordering machine, the delivering robot and the chef communication module are all in communication connection with the server. In addition, the system further comprises a label tray and a three-dimensional camera shooting device, the three-dimensional camera shooting device is arranged at the meal outlet and comprises a camera shooting control module, a three-dimensional camera shooting module, a camera shooting taking and placing device and a camera shooting communication module, wherein the three-dimensional camera shooting module, the camera shooting taking and placing device and the camera shooting communication module are in communication connection with the camera shooting control module. And an information storage module and a near field communication module are arranged in the label tray. According to the method and the system, whether own requirements are met or not can be confirmed by collecting the AR video of the played actual dish, and the confirmation process is carried out before the dish is sent out, so the system can carry out rapid error correction on the condition that detail requirements are not met.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

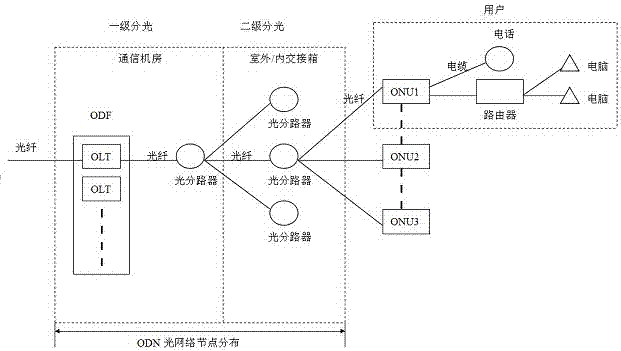

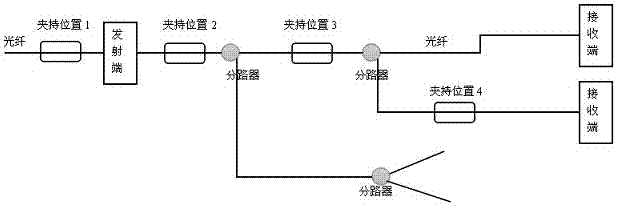

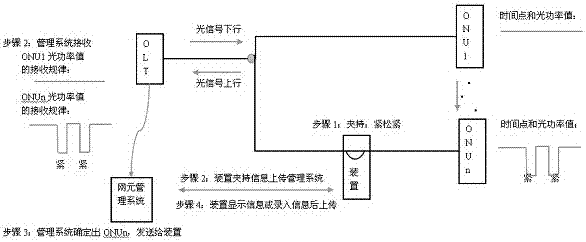

Device, system and method for detecting optical fiber routing information

InactiveCN104467954BQuick censusFast error correctionTransmission monitoring/testing/fault-measurement systemsFiberActive clamp

The invention discloses a device for detecting optical fiber routing information, which includes a mechanical clamp assembly, a clamping information acquisition module and / or a driving device, and a communication module. The mechanical clamp assembly is used to clamp and bend the optical fiber; the clamping information collection The module is used to collect the clamping rules of the mechanical fixture components; the communication module is used to transmit information, the clamping information collection module is connected to the communication module, and the driving device is used to drive the mechanical clamp components to move. The invention also discloses a system capable of detecting optical fiber routing information comprising the device and a method for detecting routing information using the system. The invention can record the clamping law of the special device by using a special device to clamp the optical fiber to make it produce optical power changes, and match the receiving end whose power change law is consistent with the change law of the optical fiber clamped by the device, thereby matching the tested optical fiber The physical geographical identification of the receiving end finally determines the user's physical routing information of the clamped optical fiber or port connection.

Owner:NANJING JIEDE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com