On-site calibration method and equipment of marine fiber bragg grating strain sensor

A strain sensor, fiber grating technology, applied in the direction of optical devices, instruments, measuring devices, etc., can solve the problems of difficult to reach the test angle, can not achieve on-site calibration, affect the calibration results, etc., to achieve convenient calibration methods and improve calibration The effect of high accuracy and calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The technical solution of the present invention is achieved in this way: a kind of on-site calibration method of marine fiber grating strain sensor is characterized in that: comprises the following steps:

[0050] S1 to establish a database: prepare the host computer, establish a database on the host computer, and set up electrical communication between the simulated board to be tested and the database;

[0051] S2 Installing the simulated board to be tested: bonding the simulated board to be tested with the optical fiber strain sensor installed on the ship to form equivalent strain;

[0052] S3 install the FBG demodulation instrument: connect the FBG strain sensor to the optical fiber joint of the FBG demodulation instrument through the transmission cable, and connect the FBG adjustment instrument to the upper electromechanical device through wires;

[0053] S4 determines the standard strain value: the strain value of the standard fiber grating sensor is measured in th...

Embodiment 2

[0063] A method for on-site calibration of a marine fiber grating strain sensor, characterized in that: comprising the steps of:

[0064] S1 to establish a database: prepare the host computer, establish a database on the host computer, and set up electrical communication between the simulated board to be tested and the database;

[0065] S2 Installing the simulated board to be tested: bonding the simulated board to be tested with the optical fiber strain sensor installed on the ship to form equivalent strain;

[0066] S3 install the FBG demodulation instrument: connect the FBG strain sensor to the optical fiber joint of the FBG demodulation instrument through the transmission cable, and connect the FBG adjustment instrument to the upper electromechanical device through wires;

[0067] S4 determines the standard strain value: the strain value of the standard fiber grating sensor is measured in the simulation test of the plate to be tested, and is recorded as Z1;

[0068] S5 st...

Embodiment 3

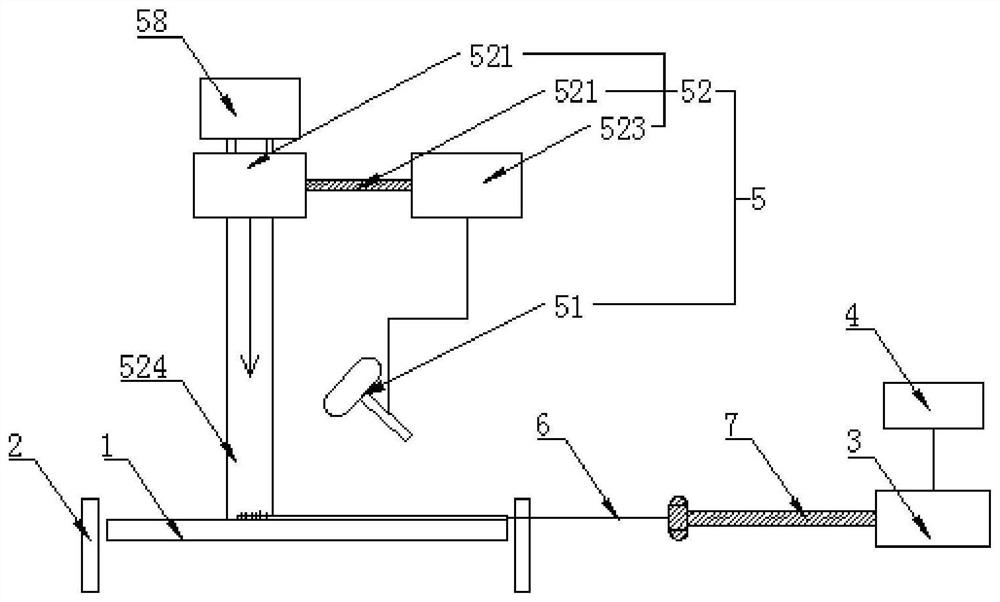

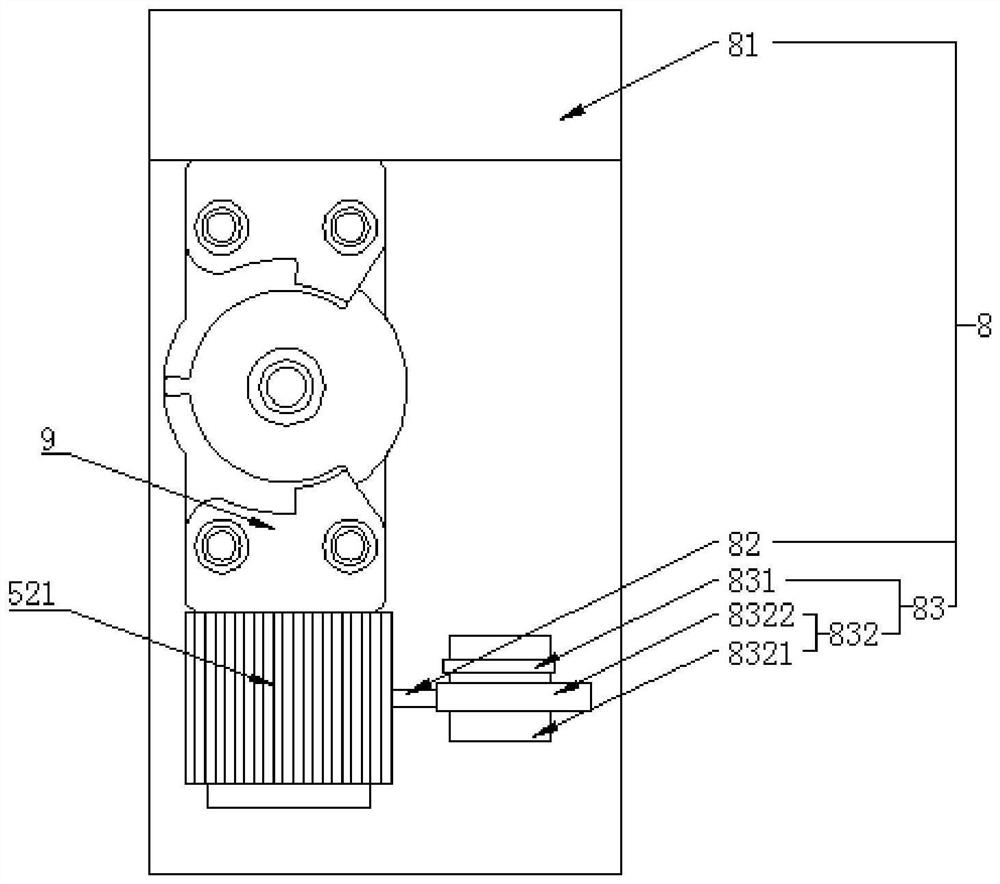

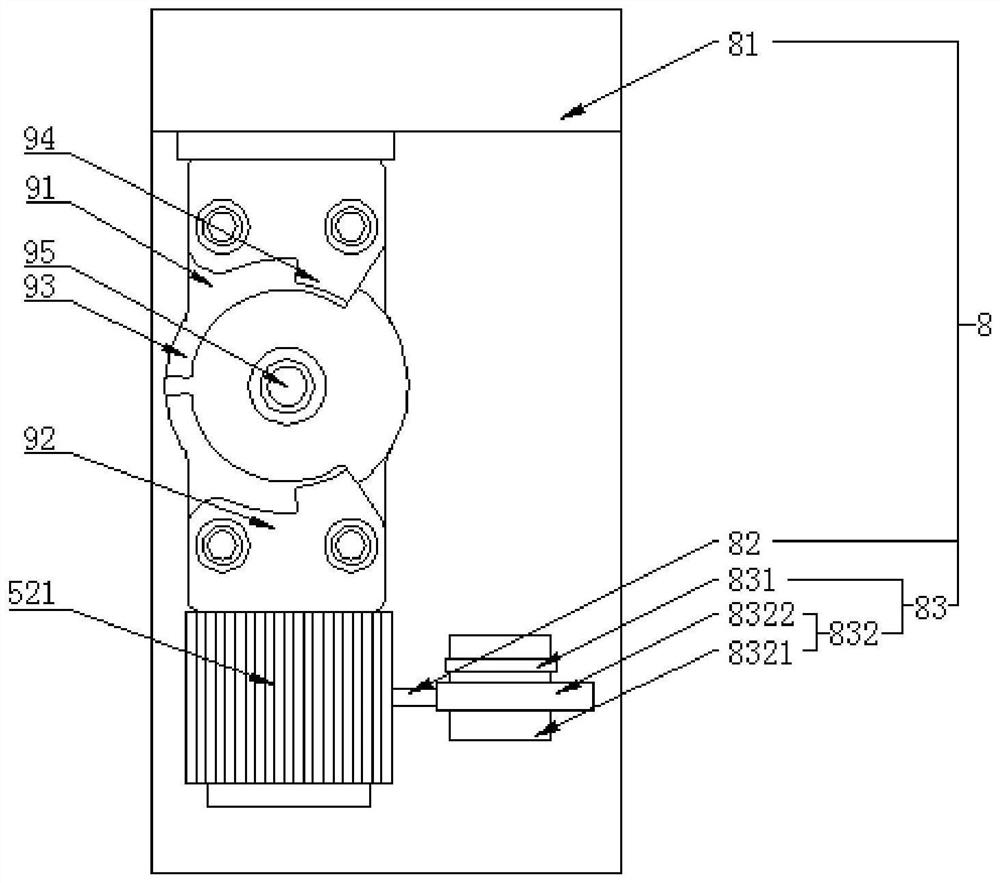

[0077] In addition, if Figure 1-2 As shown, the present invention also discloses a calibration device for a marine fiber grating strain sensor. In a specific embodiment of the present invention, it includes a simulated plate to be measured 1, a boundary support member 2, a fiber grating demodulation instrument 3, a host computer 4 and Simulated vibration analysis device 5.

[0078] Wherein, the laser lens is the PSV-400scanning head of Polytec Company; the laser scanner vibration test and analysis system is the OFV-5000vibrometer controller of Polytec Company; the model of the fiber grating solution instrument panel is SM130;

[0079] The simulated test board 1 is a rectangular flat plate of technical materials, which is installed on the boundary support member through connectors, and the optical fiber grating strain sensor to be detected is installed on the central position of the simulated test board 1 through glue, and is parallel to the simulated test board. The surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com