Trapezoidal comb tooth, electrostatic comb tooth driver and MEMS scanning mirror

A driver and comb-tooth technology, applied in the field of micro-opto-electromechanical systems, can solve the problems of linear increase and comb-tooth drive torque, and achieve the effects of increasing drive torque, reducing area, and reducing drive voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

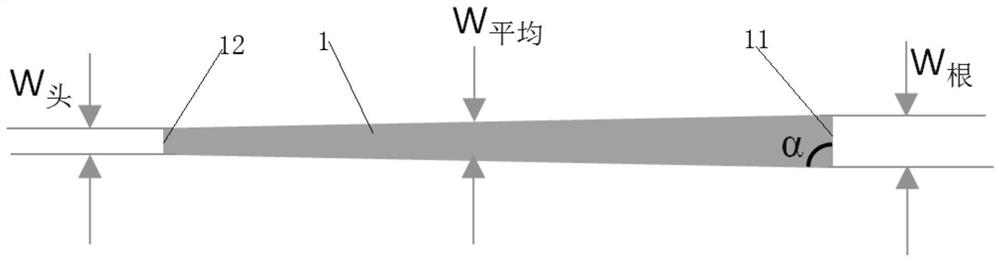

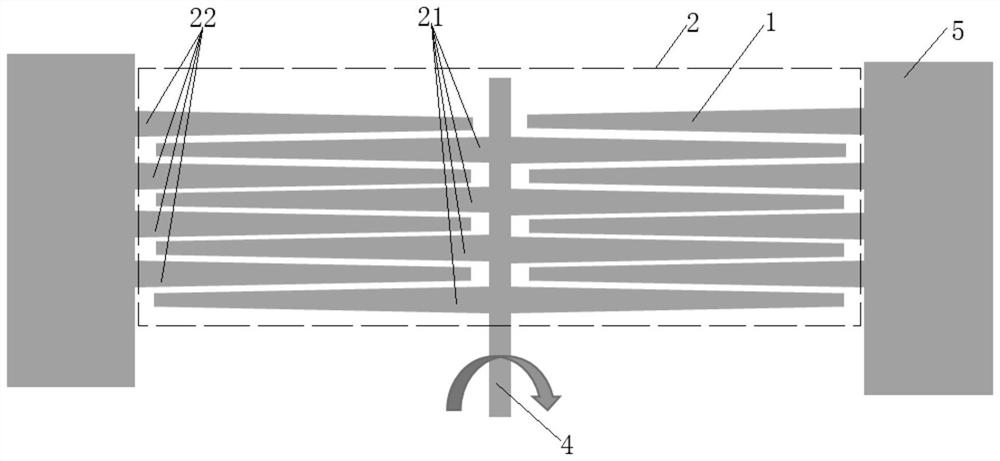

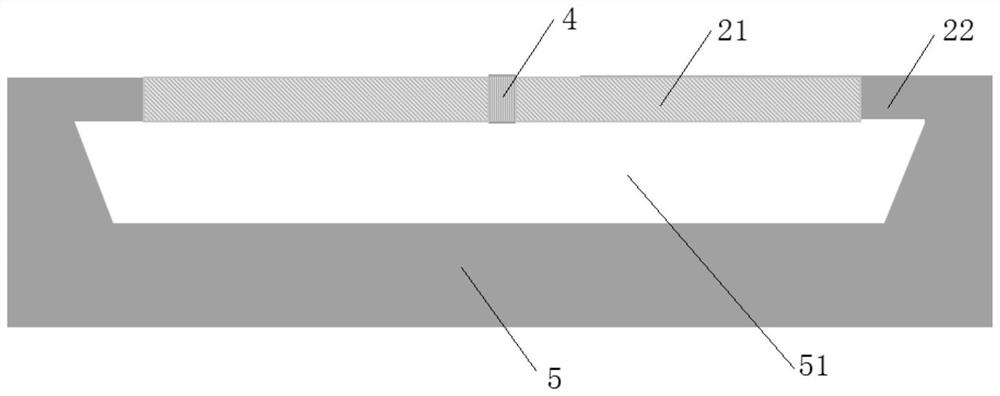

[0037] A trapezoidal comb tooth 1, such as figure 1 As shown, the root 11 width W of the trapezoidal comb tooth 1 根 Greater than head 12 width W 头 , and the width of the trapezoidal comb decreases monotonously from the root 11 of the trapezoidal comb to the head 12 of the trapezoidal comb.

[0038] In some specific embodiments of the present invention, the shape of the trapezoidal comb teeth 1 is trapezoidal. Adopt trapezoidal comb design, the width W of the root of the comb 根 Greater than comb head width W 头 , while maintaining the average comb width W 平均 Under the same condition, the stiffness of the root of the comb teeth is greatly increased, and the root of the comb teeth is the part that requires the highest stiffness of the comb teeth. The width, thus achieving th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com