B/S architecture-based hot continuous rolling rod and wire rolling force energy checking and gearbox speed ratio calculation system

A calculation system and rolling force technology, which is applied in the field of rolling force energy checking of hot continuous rolling bar and wire rod full-line rolling mill, corresponding to the calculation of gearbox speed ratio, and can solve problems that are difficult to handle, error-prone, and difficult to share and manage data and other issues, to achieve the effect of data confidentiality management and sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

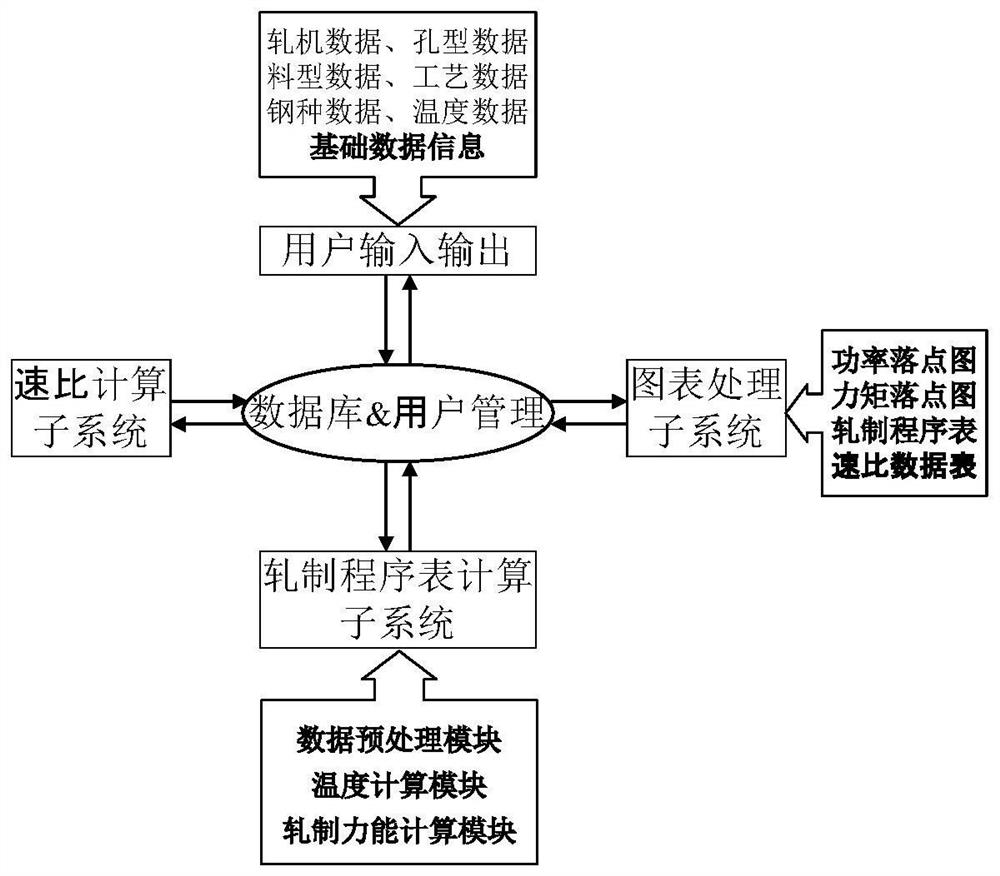

[0028] The present invention is a kind of B / S structure-based hot continuous rolling rod and wire rod rolling force energy check and gearbox speed ratio calculation system, and its specific implementation steps are:

[0029] Step 1, the user authority module, the functions include user login, user management, and authority distribution.

[0030] Step 2, the material database module, enter the name, thermal conductivity, specific heat and chemical composition, and display the material characteristic curve (thermal conductivity curve, specific heat capacity curve, CCT curve, strain rate curve).

[0031] Step 3: The production line design module creates a production line record for each physical project. The production line record includes the production line type (ordinary bar, high-speed bar, high-speed wire), rack conditions (rack number, spacing, water cooling length , water pressure, power, rotational speed, speed ratio, material coefficient, roll temperature, centralized tran...

Embodiment 2

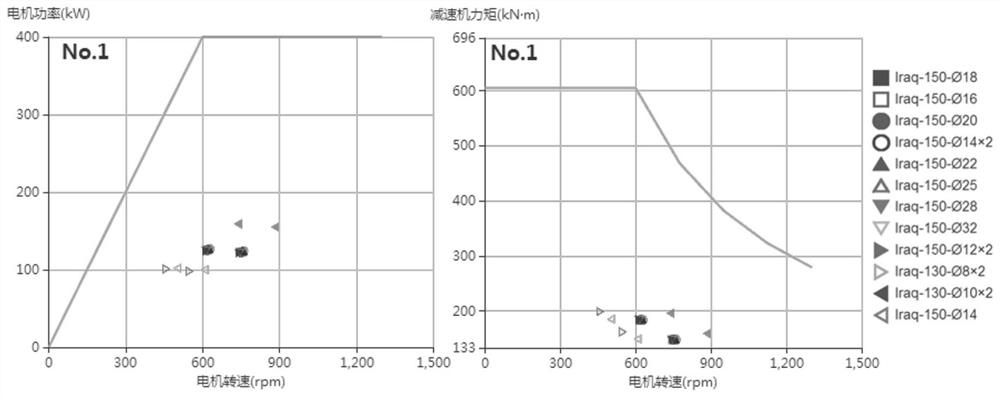

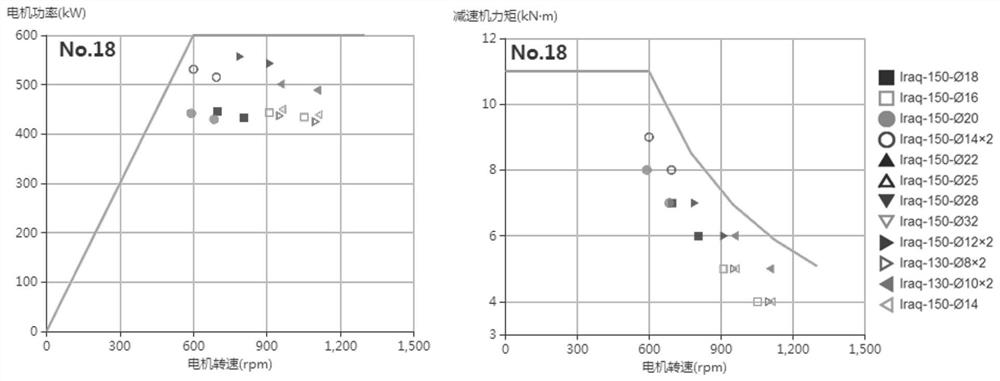

[0037] Take a bar factory with an annual output of 500,000 tons as an example: the factory has a total of 18 rolling mills, equipped with 8 sets of 400kW and 10 sets of 800kW motors, and the main product specifications are as follows: (two cuts), (two cuts), (two cuts), (single line or two cuts), as well as in and It is produced with 130mm billet, and other specifications are produced with 150mm billet. Other information of the production line, such as stand spacing, vertical state, roll diameter, roll gap, motor speed, billet weight, billet and material shape size, starting rolling temperature, and finishing rolling speed are shown in Table 1 below.

[0038] by Take the rolling program table of two split rebars as an example to calculate. The user first establishes the production line name such as "bar factory with an annual output of 500,000 tons" in the database & user management subsystem, and at the same time manually enters or uses the Excel form form bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com