Die warehouse-in and warehouse-out management system

A management system, warehouse entry and exit technology, applied in the field of mold entry and exit management system, can solve the problems of warehouse risk, warehouse occupancy, system data confusion, inconvenient goods entry and exit management, etc., to save human resources and realize collection , to avoid the effect of mold loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

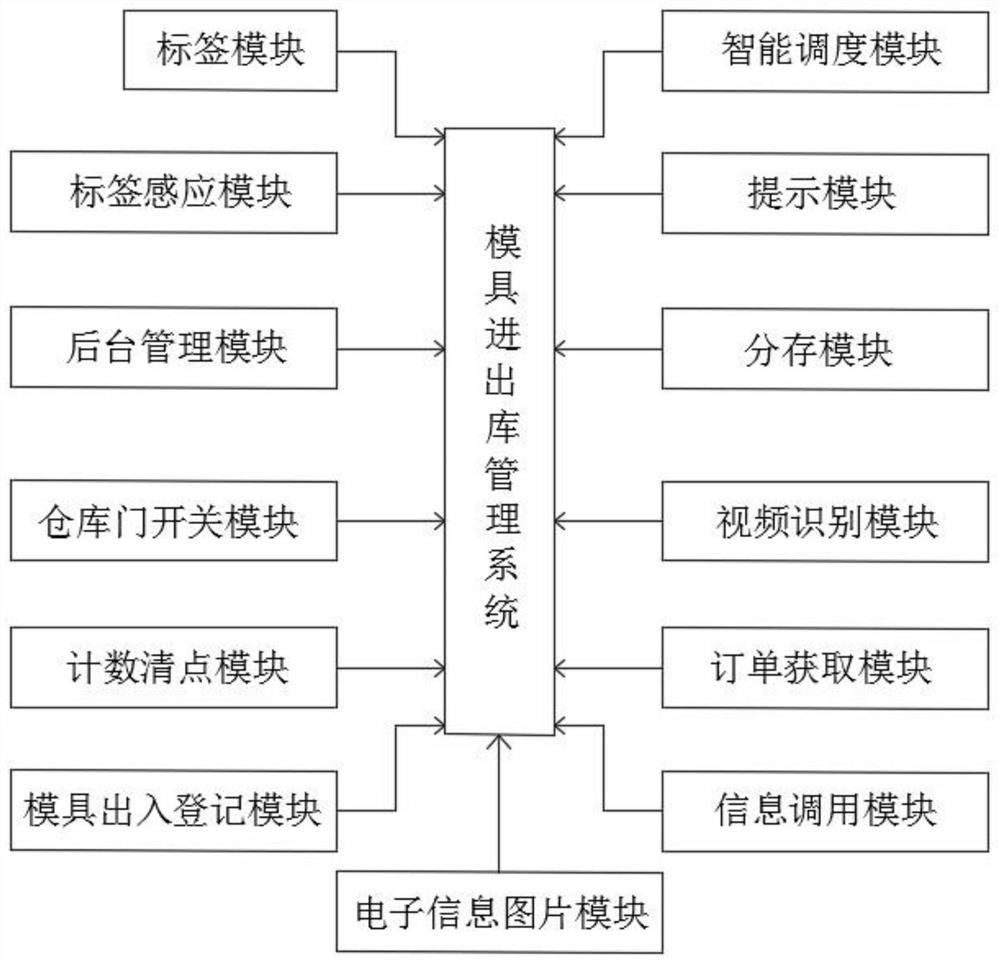

[0032] see figure 1 , the present invention provides a technical solution: a mold entry and exit management system, including a label module, a label sensing module, a background management module, a warehouse door switch module, a counting and counting module, a mold entry and exit registration module, a prompt module, and a storage module , intelligent scheduling module, video recognition module, order acquisition module, information call module and electronic information picture module;

[0033] The label module is used to store mold identification information;

[0034] The label sensing module is used to read the mold identification information stored in the label module when the mold enters the sensing area of the label sensing module, and send it to the background management module in a wired or wireless manner;

[0035] The background management module is used to match the pre-stored mold circulation information according to the mold identification information, and i...

Embodiment 2

[0054] see figure 1 , the present invention provides a technical solution: a mold entry and exit management system, including a label module, a label sensing module, a background management module, a warehouse door switch module, a counting and counting module, a mold entry and exit registration module, a prompt module, and a storage module , intelligent scheduling module, video recognition module, order acquisition module, information call module and electronic information picture module;

[0055] The label module is used to store mold identification information;

[0056] The label sensing module is used to read the mold identification information stored in the label module when the mold enters the sensing area of the label sensing module, and send it to the background management module in a wired or wireless manner;

[0057] The background management module is used to match the pre-stored mold circulation information according to the mold identification information, and i...

Embodiment 3

[0072] see figure 1 , the present invention provides a technical solution: a mold entry and exit management system, including a label module, a label sensing module, a background management module, a warehouse door switch module, a counting and counting module, a mold entry and exit registration module, a prompt module, and a storage module , intelligent scheduling module, video recognition module, order acquisition module, information call module and electronic information picture module;

[0073] The label module is used to store mold identification information;

[0074] The label sensing module is used to read the mold identification information stored in the label module when the mold enters the sensing area of the label sensing module, and send it to the background management module in a wired or wireless manner;

[0075] The background management module is used to match the pre-stored mold circulation information according to the mold identification information, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com