Composite catalyst for removing NOx and smoke dust as well as preparation method and application of composite catalyst

A composite catalyst, SCR catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. problems, to achieve the effect of improving stability, preventing fouling and clogging, and reducing the frequency of purging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

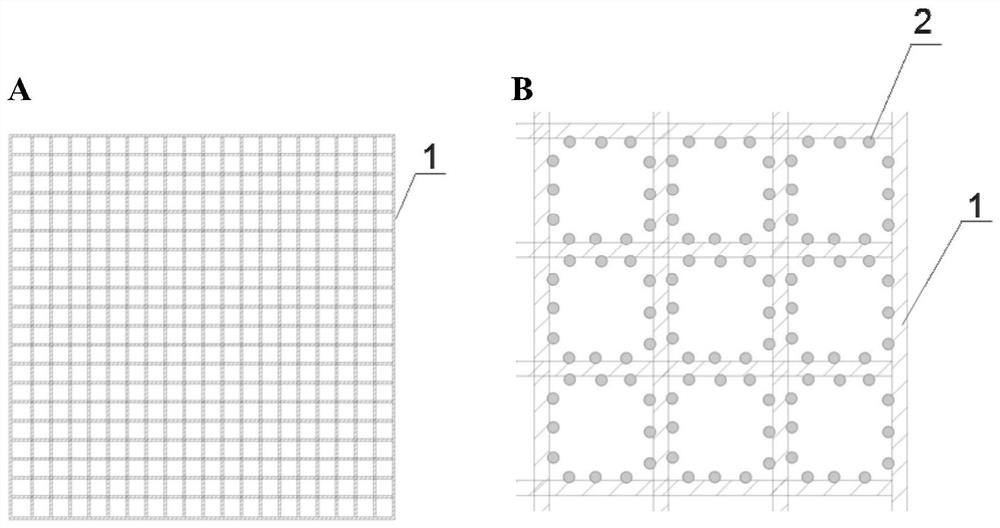

Image

Examples

Embodiment 1

[0044] In this embodiment, a composite catalyst and preparation method for removing NOx and soot are provided, and the preparation method includes the following steps:

[0045] (1) Preparation of perovskite-type PM catalyst: Weigh the nitrate (Co( NO 3 ) 2 : Pd(NO 3 ) 2 : SrNO 3 : La(NO 3 ) 3 =0.9:0.1:0.2:0.8; dissolve in deionized water and stir evenly, then add citric acid (C 6 h 8 o 7 ), temperature controlled (80°C) and stirred for 12h until the solution was evaporated to dryness and turned into a translucent gel, and the above wet gel was dried at 120°C to obtain dry La0.8Sr0.2Co0.9Pd0.1O 3 precursor.

[0046] (2) Dissolve the above precursor in deionized water, stir under temperature control, and make honeycomb V 2 o 5 / WO 3 / TiO 2 The catalyst carrier is immersed in the solution for several hours, and then dried and calcined in a muffle furnace. The calcining process is carried out in two stages. After calcining at a medium temperature for several hours, i...

Embodiment 2

[0049] In this embodiment, a composite catalyst and preparation method for removing NOx and soot are provided, and the preparation method includes the following steps:

[0050] (1) Preparation of perovskite-type PM catalyst: Weigh the nitrate (Co( NO 3 ) 2 : Pd(NO 3 ) 2 : SrNO 3 : La(NO 3 ) 3 =0.8:0.2:0.15:0.85; dissolve in deionized water and stir evenly, then add citric acid (C 6 h 8 o 7 ), stirred at a controlled temperature (75°C) for 10 hours until the solution was evaporated to dryness and turned into a translucent gel, and dried at 110°C to obtain dry La0.85Sr0.15Co0.8Pd0.2O 3 precursor.

[0051] (2) Dissolve the above precursor in deionized water, stir under temperature control, and make honeycomb V 2 o 5 / WO 3 / TiO 2 The catalyst carrier is immersed in the solution for several hours, and then dried and calcined in a muffle furnace. The calcining process is carried out in two stages. After calcining at a medium temperature for several hours, it is calcine...

Embodiment 3

[0053] In this embodiment, a composite catalyst and preparation method for removing NOx and soot are provided, and the preparation method includes the following steps:

[0054] (1) Preparation of perovskite-type PM catalyst: Weigh the nitrate (Co( NOx) 2 : Pd(NOx) 2 : SrNOx: La(NOx) 3 =0.9:0.1:0.1:0.9; dissolve in deionized water and stir evenly, then add citric acid (C 6 h 8 o 7 ), stirred at temperature (85°C) for 14h until the solution evaporated to dryness and turned into a translucent gel, and dried the above wet gel at 130°C to obtain dry La0.9Sr0.1Co0.9Pd0.1O 3 precursor.

[0055] (2) Dissolve the above precursor in deionized water, stir under temperature control, and make honeycomb V 2 o 5 / WO 3 / TiO 2 The catalyst carrier is immersed in the solution for several hours, and then dried and calcined in a muffle furnace. The calcining process is carried out in two stages. After calcining at a medium temperature for several hours, it is calcined at a high temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com