Trichlorfon continuous production method and production device for method

A production method and production device technology, applied in the field of trichlorfon continuous production and the production device used for it, can solve the problems of poor production stability and safety, poor product quality, low production efficiency, etc., and achieve stable product quality , Quick effect, less investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preparation method and production device for the continuous production of trichlorfon of the present invention will be described in detail below through specific embodiments.

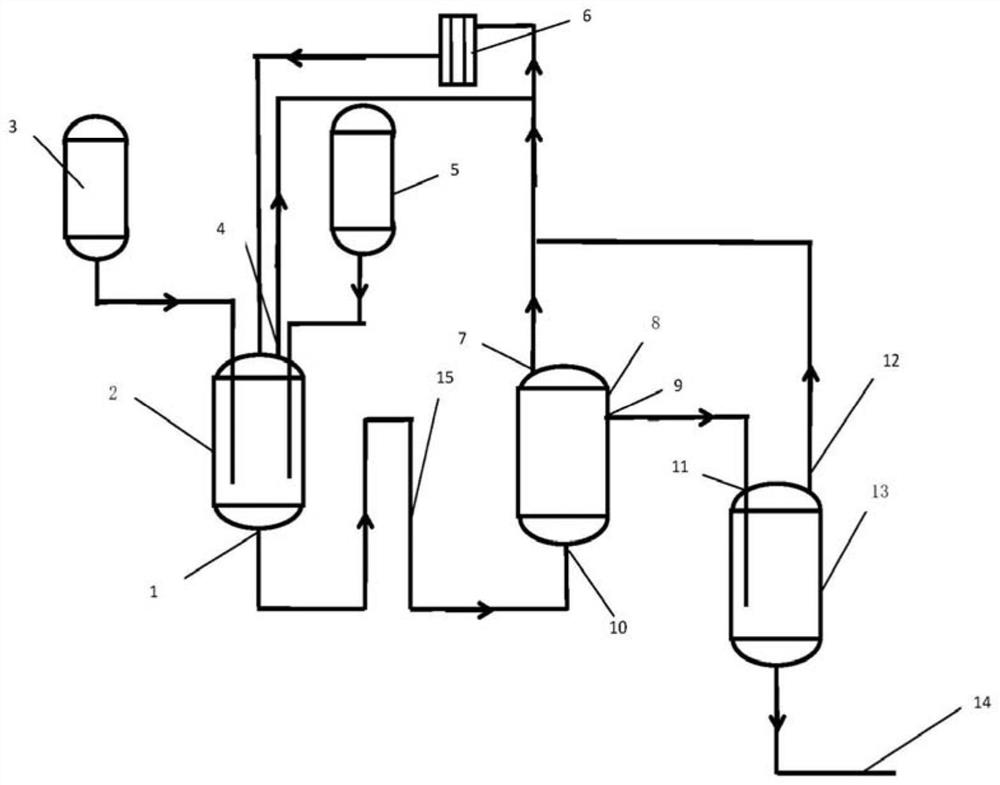

[0027] Such as figure 1 As shown, first put about 900kg of 90% trichlorfon into the first-level synthesis kettle as the reaction mother liquid of the synthesis kettle, and then drop two kinds of chloral and dimethyl phosphite at the same time through the flow meter at a ratio of 1:0.6. The raw materials are sent to the first-level synthesis tank for reaction, and the reaction temperature is controlled at 75-85°C. The reaction materials in the first-level synthesis kettle flow out from the bottom liquid outlet 1, through the liquid outlet pipe 15 to the bottom liquid inlet 10 of the second-level synthesis kettle, and overflow into the second-level synthesis kettle through the n-type pipeline to continue the reaction. 75°C. The reaction product in the second-stage synthesis kettle overflows i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com