Connecting joint of prefabricated steel reinforced concrete column and profiled steel sheet composite plate and construction method

A technology for concrete columns and profiled steel plates, which is applied in construction and building construction, etc., can solve the problems of low strength, high cost of steel structures, and heavy concrete floor slabs, so as to reduce the self-weight of the structure, improve the integrity, and take into account the construction efficiency and economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

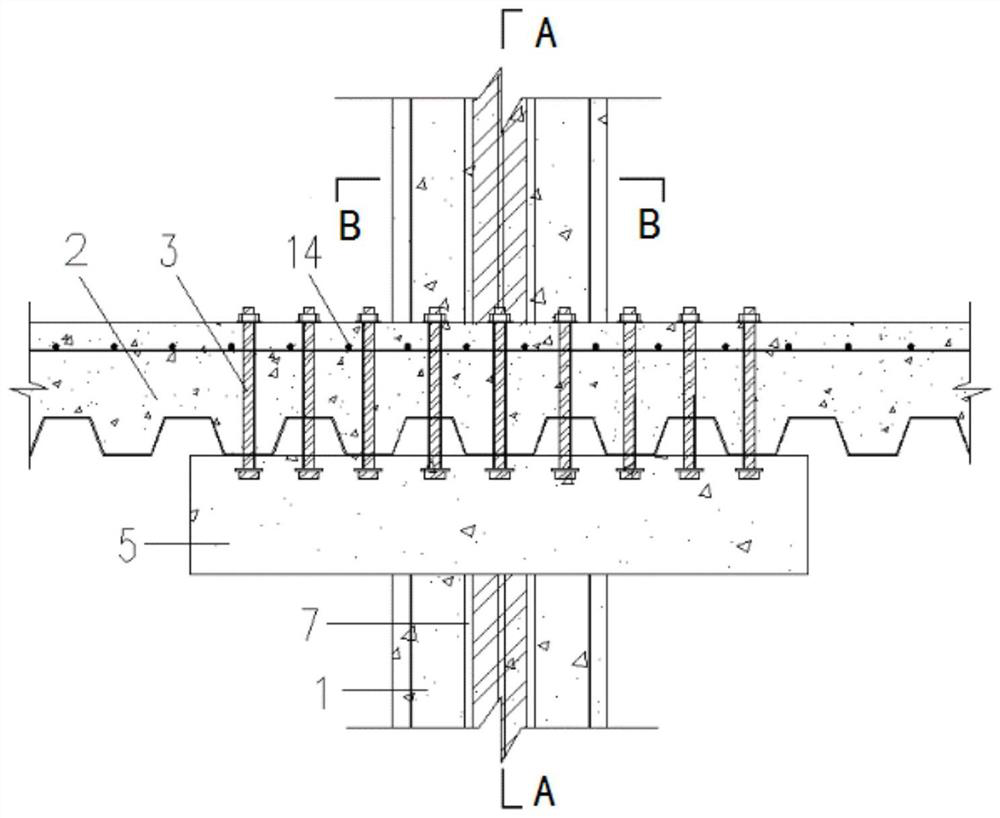

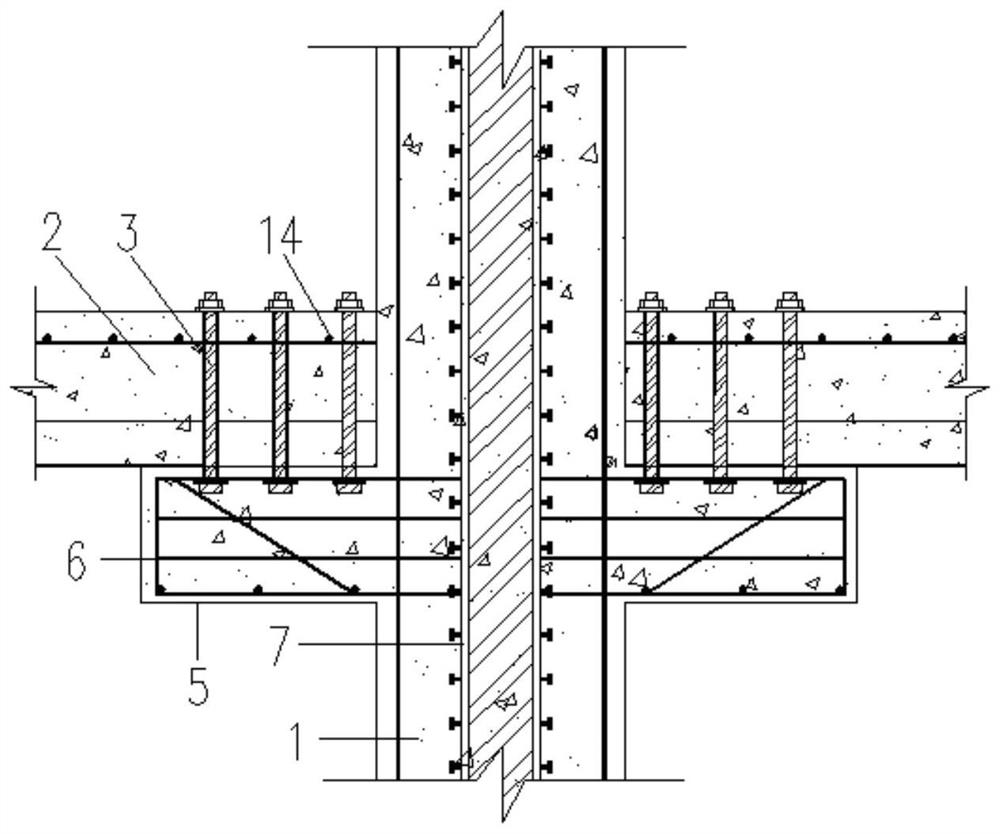

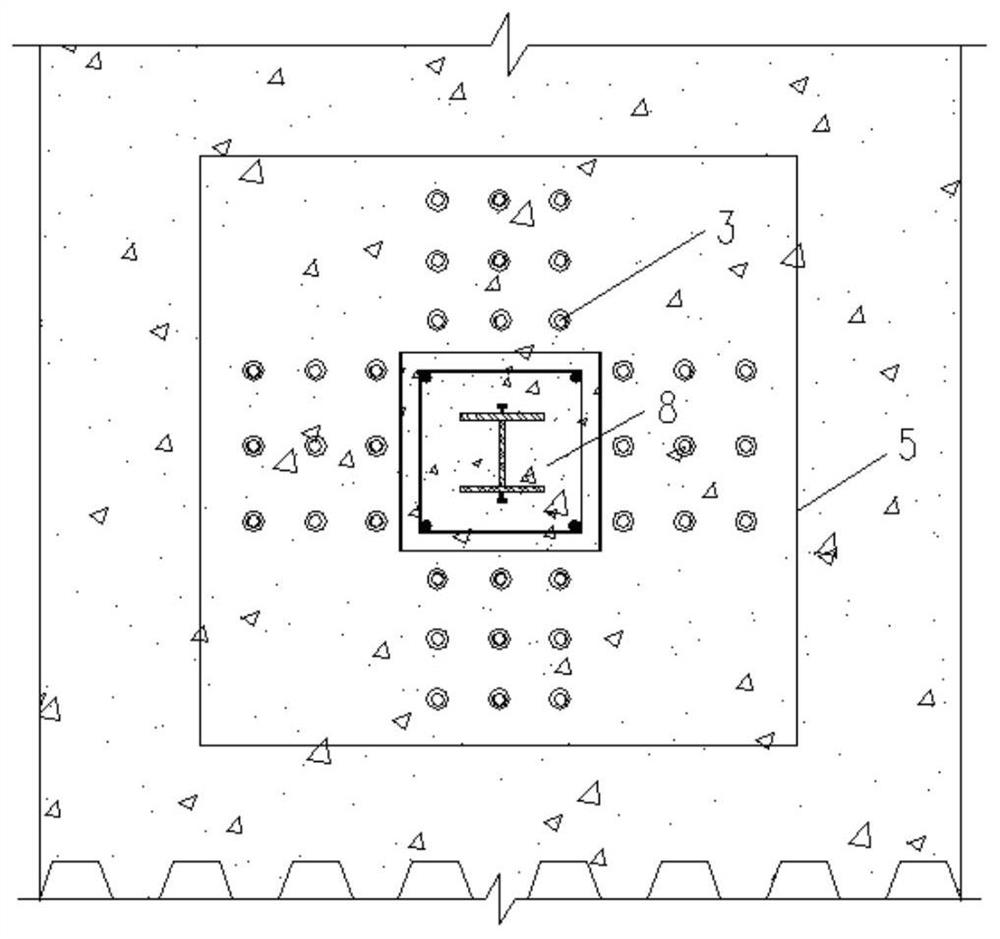

[0039] Such as Figure 1~4 As shown in the figure, a connection node between a prefabricated steel concrete column and a profiled steel plate composite plate is connected by a supporting plate and embedded bolts, including a prefabricated steel concrete column 1, a profiled steel plate composite plate 2, a supporting plate 5 and embedded bolts 3. A prefabricated steel concrete column reserved hole is opened in the middle of the profiled steel plate composite plate 2, and the prefabricated steel concrete column 1 is installed in the reserved hole of the prefabricated steel concrete column; the supporting plate 5 is located on the profiled steel plate On the prefabricated steel concrete column 1 below the composite plate 2, the supporting plate 5 and the prefabricated steel concrete column 1 adopt an integrated prefabricated structure; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap