Bridge wind tunnel wind speed and vehicle force measurement test system and method

A force measurement test and wind tunnel technology, which can be used in vehicle testing, aerodynamic testing, and machine/structural component testing. , to reduce manual interference, improve efficiency and accuracy, and reduce the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

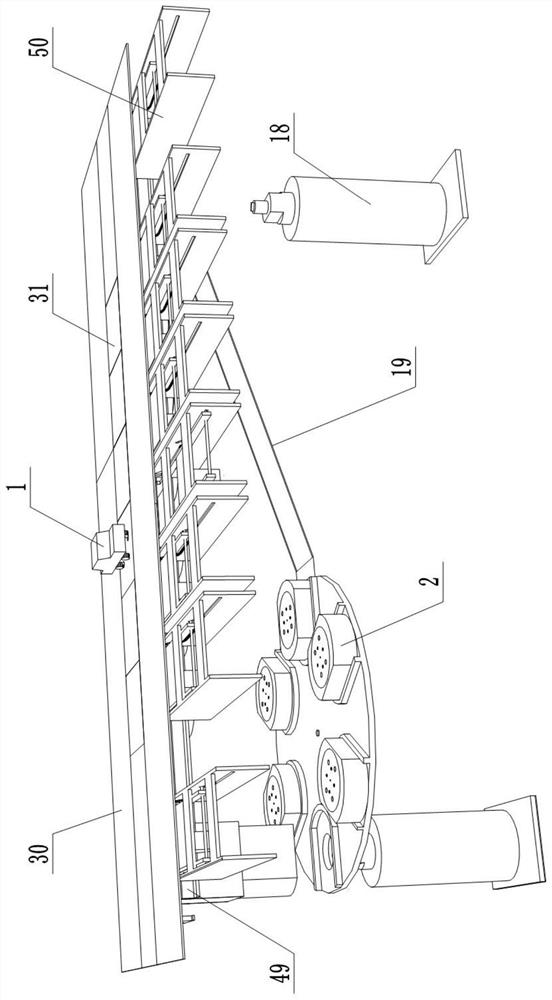

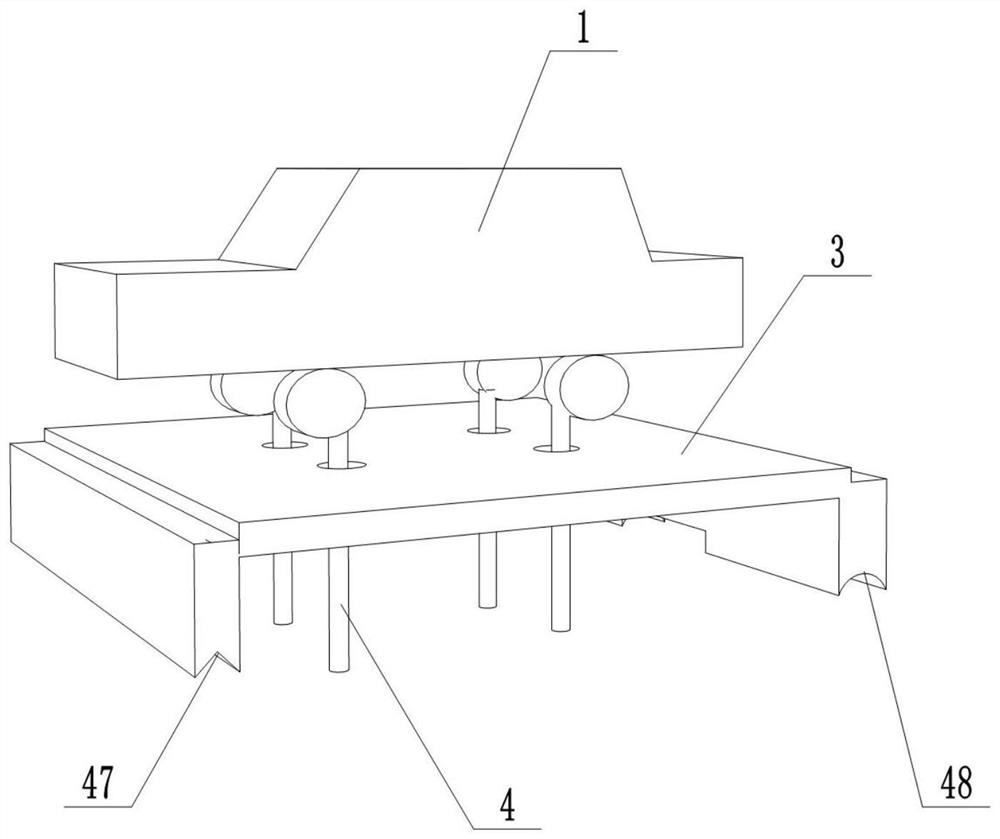

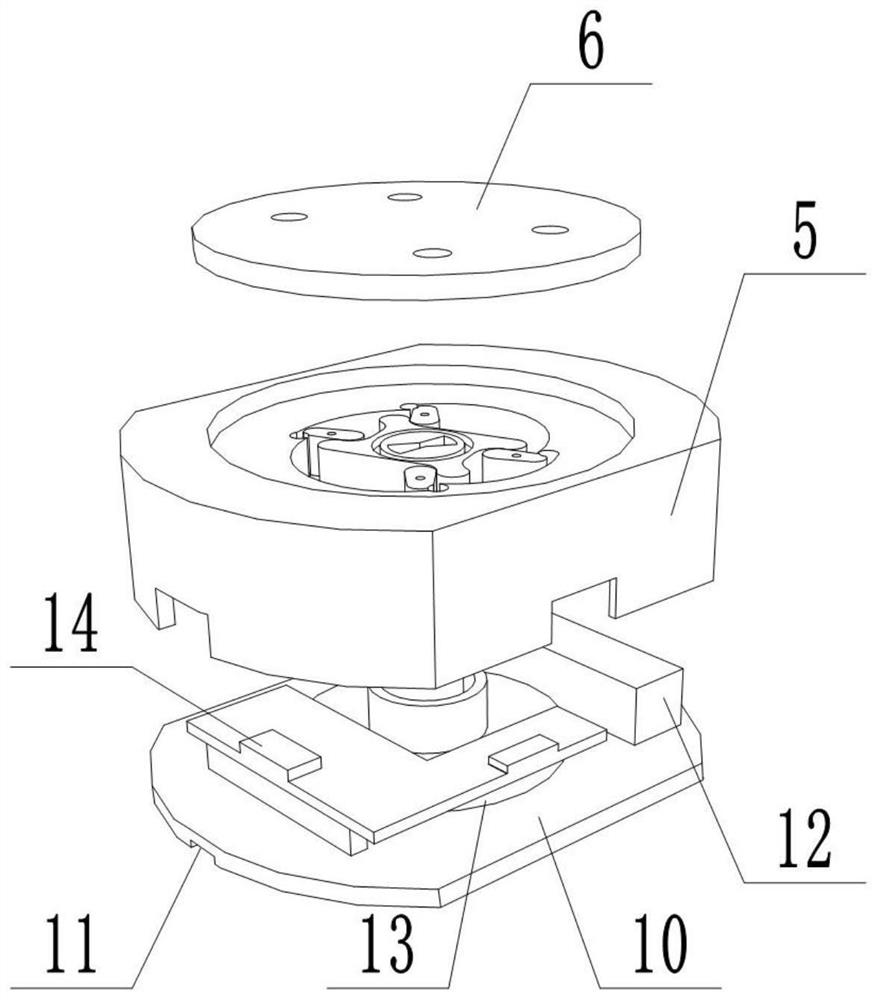

[0068] Such as Figure 1-Figure 5a , Figure 6-Figure 11a , Figure 12-Figure 14 Shown: This embodiment provides a kind of bridge wind tunnel wind speed and vehicle force measurement test system, comprises vehicle model 1, force balance 2, wind measurement platform and force measurement platform, and wind measurement platform comprises wind measurement crane, wind measurement The platform is set inside the wind tunnel and used to measure wind speed and wind direction at different positions. The force measuring platform is set inside the bridge model. The force measuring platform includes a mechanical servo system. The vehicle model 1 is locked on the force measuring balance 2, and the force measuring balance 2 is used for For measuring the six-component force of the vehicle model 1, a mechanical servo system is used to transport and move the force measuring balance 2. In this embodiment, through the cooperation of the wind measuring platform and the force measuring platform,...

Embodiment 2

[0088] Such as Figure 5bAs shown, the difference between this embodiment and Embodiment 1 is that the clamping device also includes a locking pressure plate 15 and a pressure plate 52, the locking pressure plate 15 is arranged outside the locking groove 8, and the pressure plate 52 is arranged on the locking pressure plate 15 The outer side of the plate 52 is fixedly connected with the locking pressure plate 15, and the edge of the pressure plate 52 is provided with four protrusions, and each protrusion is in contact with a load cell 4. Inserting the locking groove 8 through the lifting rod key plate 9 drives the locking pressure plate 15 and the pressure plate 52 to rotate at a certain angle, and each protrusion presses the force measuring rod 4 into the draw-in groove of the force measuring inner ring 7 .

Embodiment 3

[0090] Such as Figure 11b As shown, the difference between this embodiment and Embodiment 1 or Embodiment 2 is that a sliding platform is provided on the force measuring platform, and the sliding platform includes fixed cover plates 30 on both sides of the force measuring platform and several sliding panels on the force measuring platform. Cover plate 31, each sliding cover plate 31 is all driven by a sliding mechanism 50; Each sliding mechanism all 50 comprises the second cover plate motor 53, lifting structure, push rod 54 and base 55, the slide rail seat of lifting structure and base 55 Sliding connection; the lifting structure includes two groups of symmetrically arranged connecting rod groups, each connecting rod group includes a first connecting rod 56, a second connecting rod 57, a third connecting rod 58 and a fourth connecting rod 59, and the first connecting rod 56 Set in parallel with the third connecting rod 58, the second connecting rod 57 and the fourth connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com