Microscope objective lens

A microscope objective lens and lens technology, which is applied in the field of microscope objective lens, can solve the problems of low resolution performance, large number of lenses, and difficult processing, and achieve high resolution performance, ensure optical performance, and reduce processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

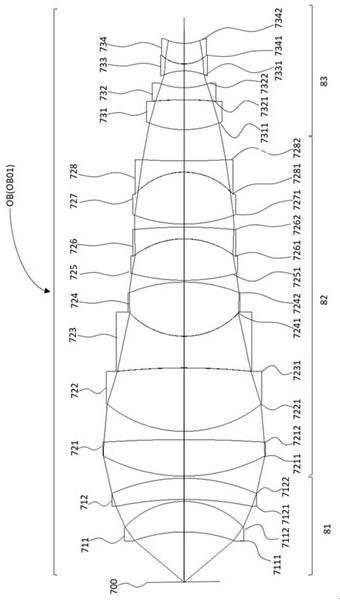

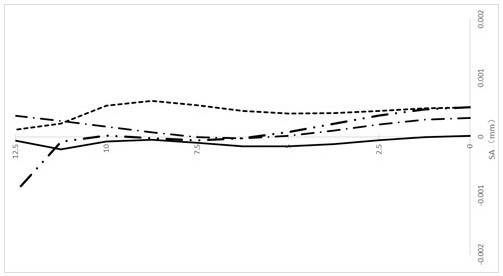

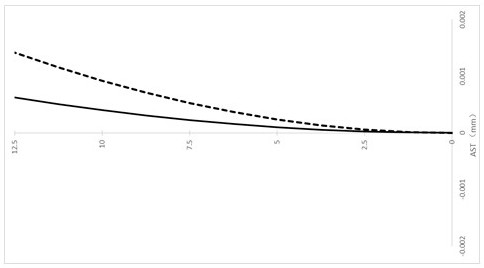

[0073] Such as figure 1 As shown, the microscope objective lens OB01 of the first embodiment includes a first lens group 81, a second lens group 82 and a third lens group 83, wherein the first lens group 81 includes a first lens 711 with positive refractive power and a positive refractive power The second lens 712. The surface of the first lens 711 facing the object side is the first surface 7111 , and the surface facing the image side is the second surface 7112 . The surface of the second lens 712 facing the object side is the first surface 7121 , and the surface facing the image side is the second surface 7122 . The second lens group 82 includes a third lens 721, a fourth lens 722, a fifth lens 723, a sixth lens 724, a seventh lens 725, an eighth lens 726, and a ninth lens 727 arranged in sequence from the object side to the image side. , the tenth lens 728 . The third lens 721 has positive refractive power, the surface facing the object side is the first surface 7211 , a...

Embodiment 2

[0086] Such as Image 6 As shown, the structure of the microscope objective lens OB02 in the second embodiment is similar to that of the first embodiment, and also includes a first lens group 81, a second lens group 82, a third lens group 83, a first lens 711, and a second lens 712 , third lens 721, fourth lens 722, fifth lens 723, sixth lens 724, seventh lens 725, eighth lens 726, ninth lens 727, tenth lens 728, eleventh lens 731, twelfth lens The difference among the lens 732 , the thirteenth lens 733 , and the fourteenth lens 734 is that the material of the first lens 711 is selected, and the optical parameters of each lens are slightly different from those in the first embodiment.

[0087] Specifically, in the microscope objective lens of the second embodiment, the focal length f11 of the first lens 711 is 14.79, the refractive index N11 is 1.91, the Abbe number V11 is 36.2, and the thickness T11 is 2.89. The focal length f12 of the second lens 712 is 40.66, the refractiv...

Embodiment 3

[0098] Such as Figure 11 As shown, the structure of the microscope objective lens in the third embodiment is similar to that of the first embodiment, and also includes the first lens group 81, the second lens group 82, the third lens group 83, the first lens 711, the second lens 712, Third lens 721, fourth lens 722, fifth lens 723, sixth lens 724, seventh lens 725, eighth lens 726, ninth lens 727, tenth lens 728, eleventh lens 731, twelfth lens 732, the thirteenth lens 733, and the fourteenth lens 734. The difference is that the first lens 711 is made of a material with a relatively high refractive index, and the optical parameters of each lens are slightly different from those in Embodiment 1.

[0099] Specifically, in the microscope objective lens of the third embodiment, the focal length f11 of the first lens 711 is 14.19, the refractive index N11 is 1.94, the Abbe number V11 is 31.7, and the thickness T11 is 2.89. The focal length f12 of the second lens 712 is 47.74, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com