Digital twin smart cloud scheduling method meeting personalized customization production

A scheduling method and smart cloud technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as high costs and production delays, and achieve the effects of eliminating machine failures, reducing manufacturing risks, and improving reliability and availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

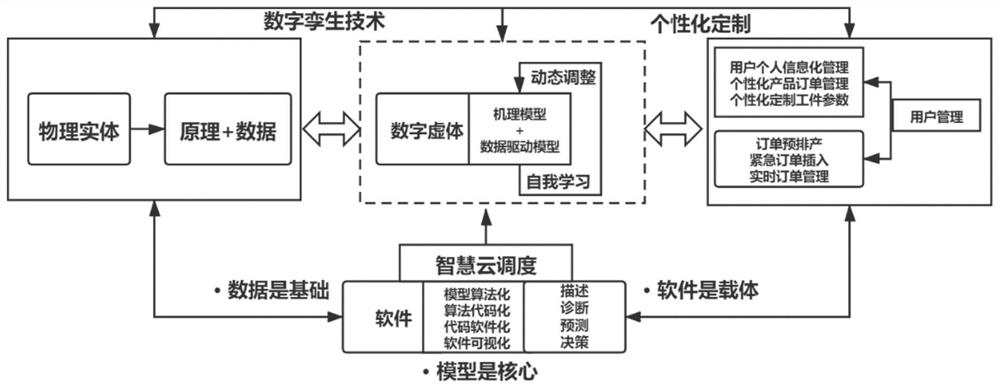

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

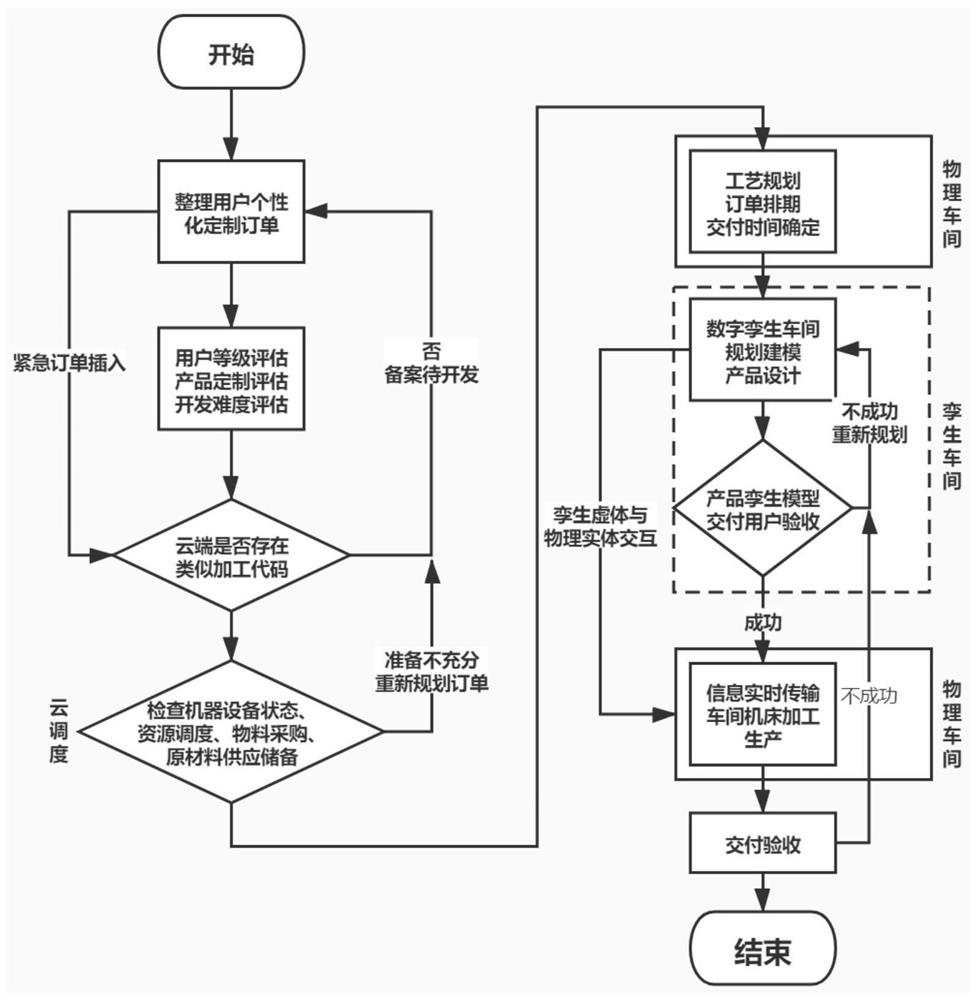

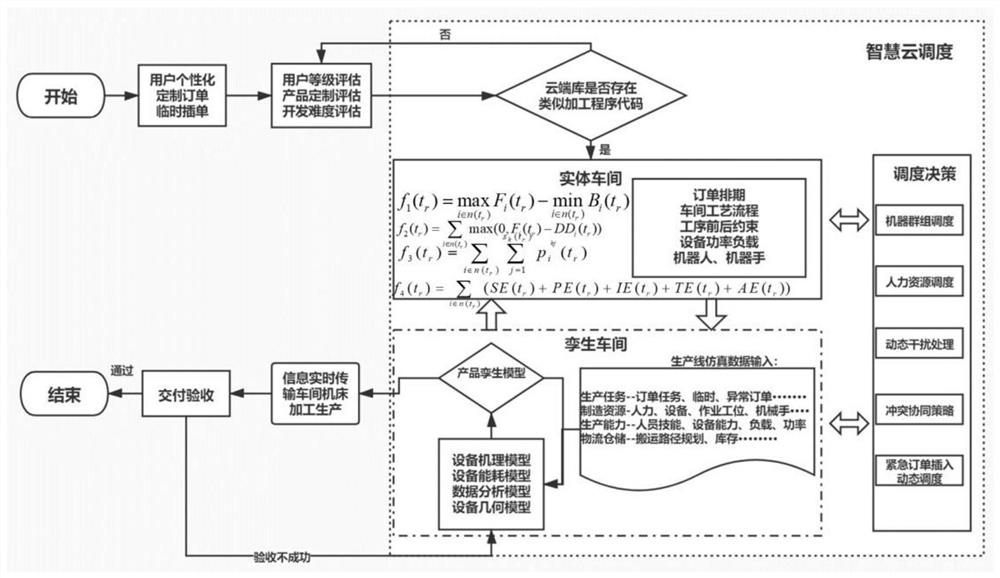

[0040] A digital twin smart cloud scheduling method that meets personalized customized production, such as figure 1 shown, including the following steps:

[0041] Step 1: The user submits a personalized demand order, which includes the number of workpieces, process parameters, and product specification information;

[0042] Step 2: The production planning department conducts process design for personalized orders, generates cloud codes for each workpiece process and process constraint parameters corresponding to the process, and uploads equipment parameters and personalized order attribute parameters to the cloud system;

[0043] Step 3: The cloud scheduling system perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com