Full-automatic bead stringing machine

A kind of bead threading machine, fully automatic technology, applied in jewelry, clothing, applications, etc., can solve the problems of high production cost, different pearl sizes, low mechanization degree, etc., achieve high production capacity, improve bead threading efficiency, and high degree of mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

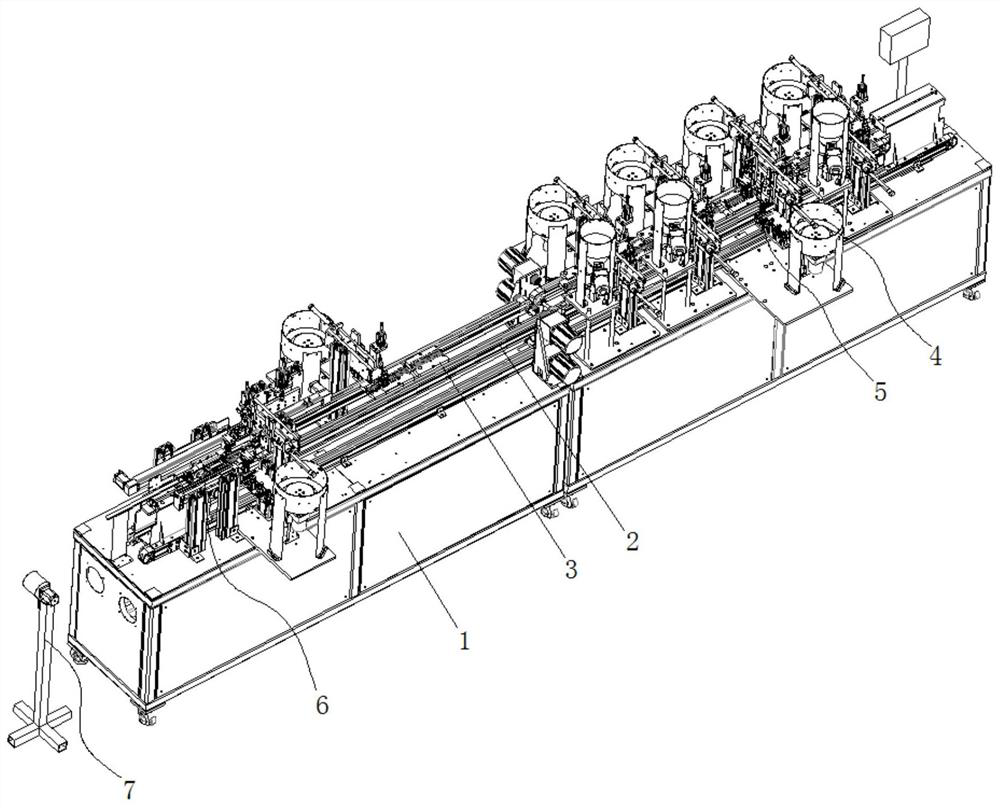

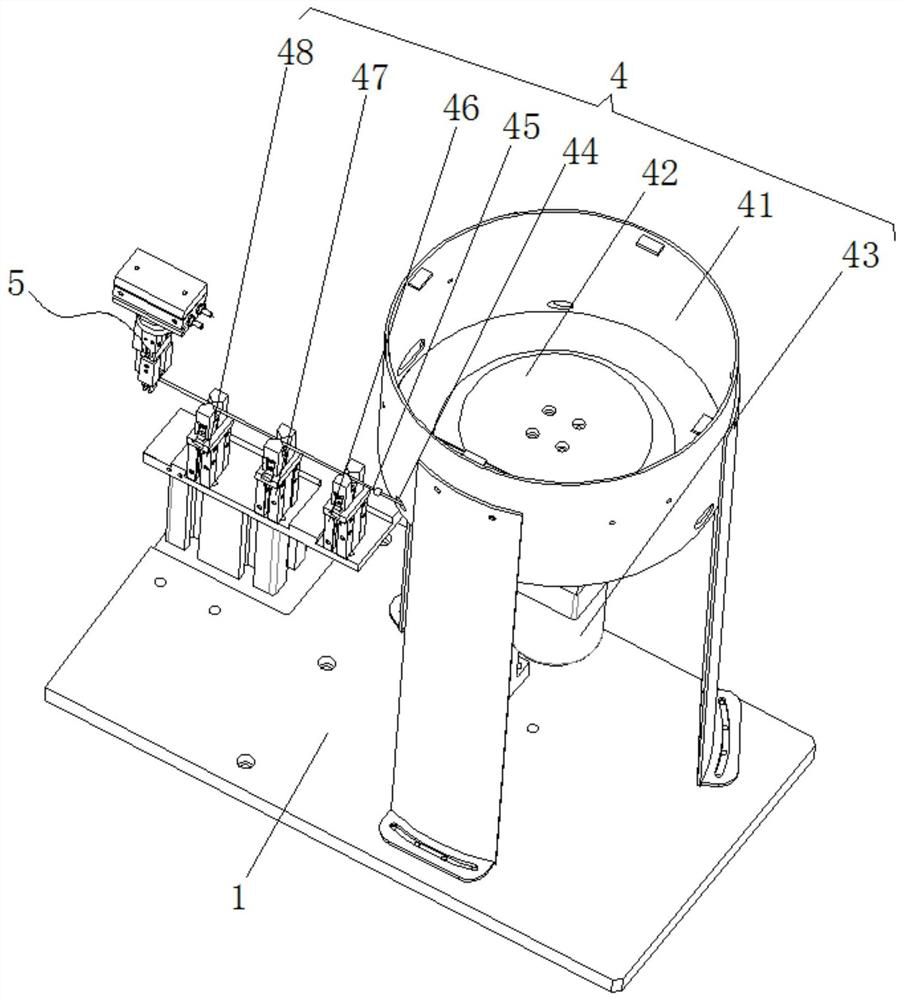

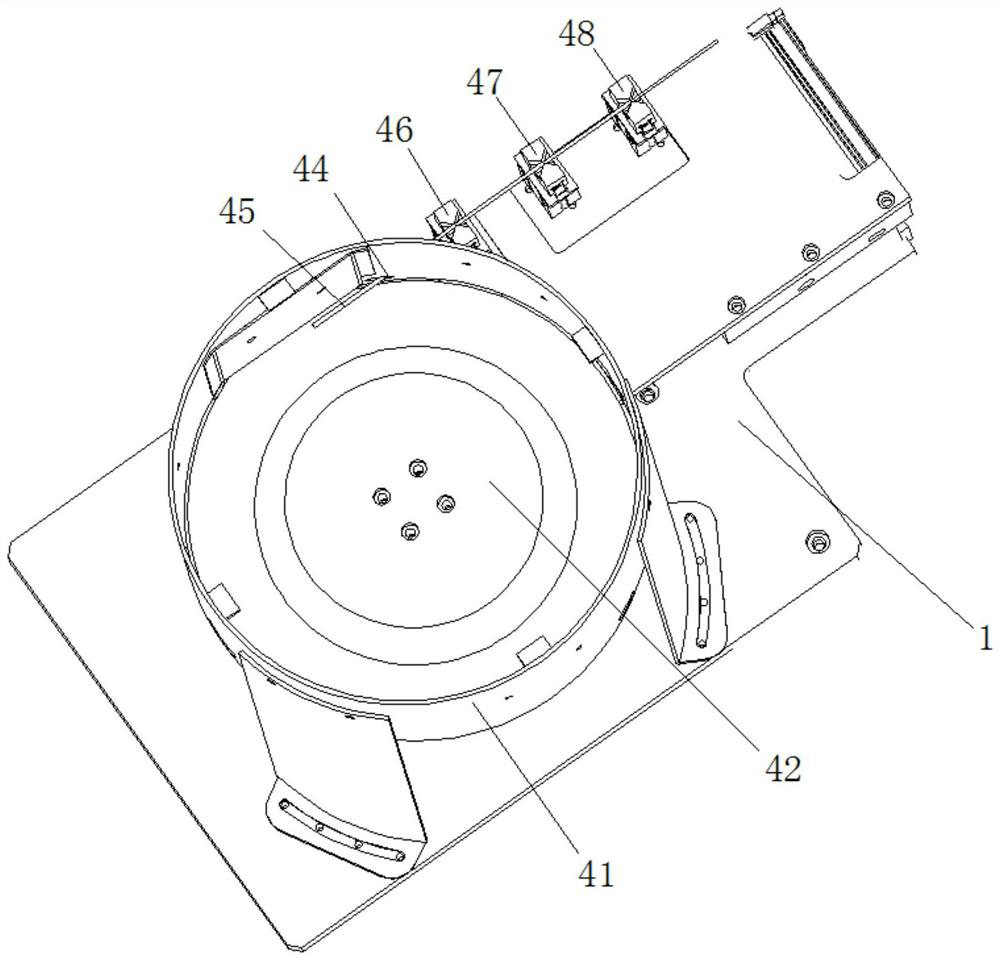

[0028] Embodiments of the present invention provide a fully automatic bead threading machine, such as Figure 1-6 As shown, it includes a frame 1, a circular conveyor belt 2, a number of pearl placement and arrangement mechanisms 3, a number of pearl feeding mechanisms 4, a pearl grasping mechanism 5, and a thread threading mechanism 6;

[0029] The endless conveyor belt 2 is horizontally arranged on the frame 1. The circulating conveyer belt 2 is an existing commercially available product, and is used to convey the array plates 31 successively through each pearl feeding mechanism 4, finally deliver to the silk thread mechanism 6, and finally circulate downwards.

[0030] Such as Figure 4 As shown, the pearl placement and arrangement mechanism 3 includes an arrangement plate 31, several ejector rods 33 and some clamping cylinders 34, and several arrangement plates 31 are equidistantly arranged on the endless conveyor belt 2, and the arrangement plate 31 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com