Special camshaft pre-cleaning equipment

A pre-cleaning and camshaft technology, which is applied to cleaning methods using liquids, lighting and heating equipment, cleaning methods and utensils, etc., can solve problems affecting work efficiency, splashing, limited cleaning pressure, etc., to improve cleaning efficiency, The effect of avoiding splashing phenomenon and improving energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

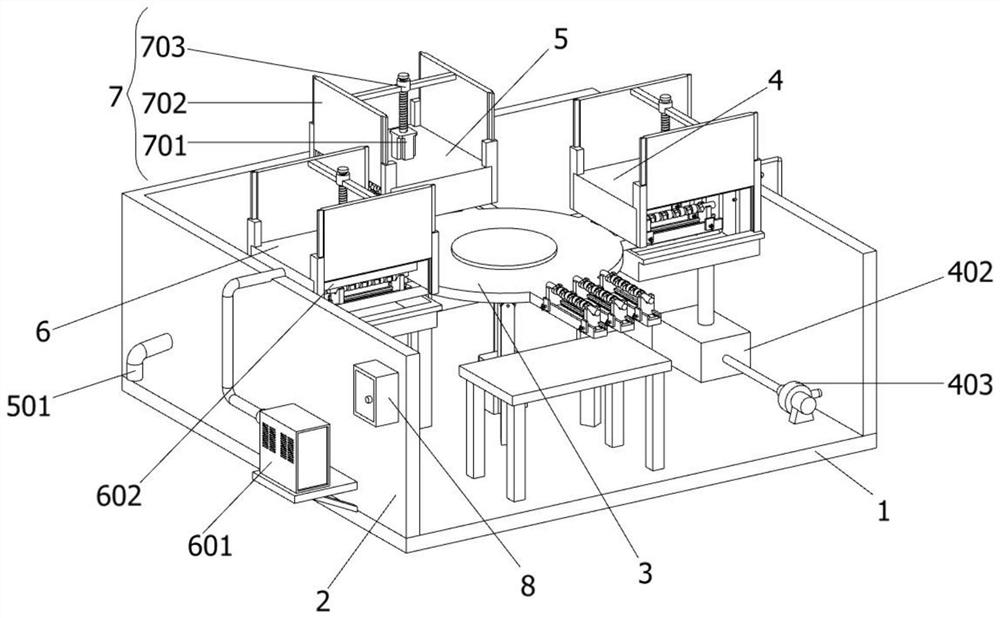

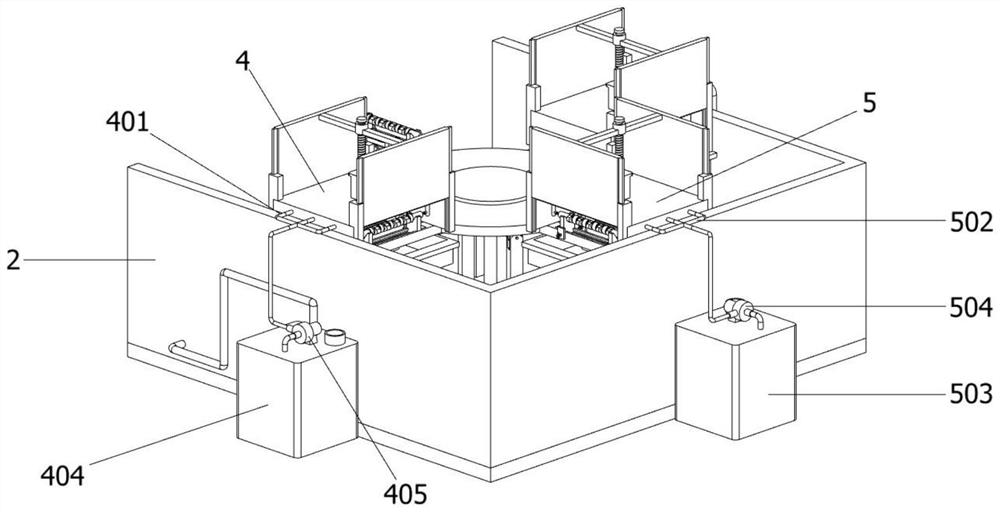

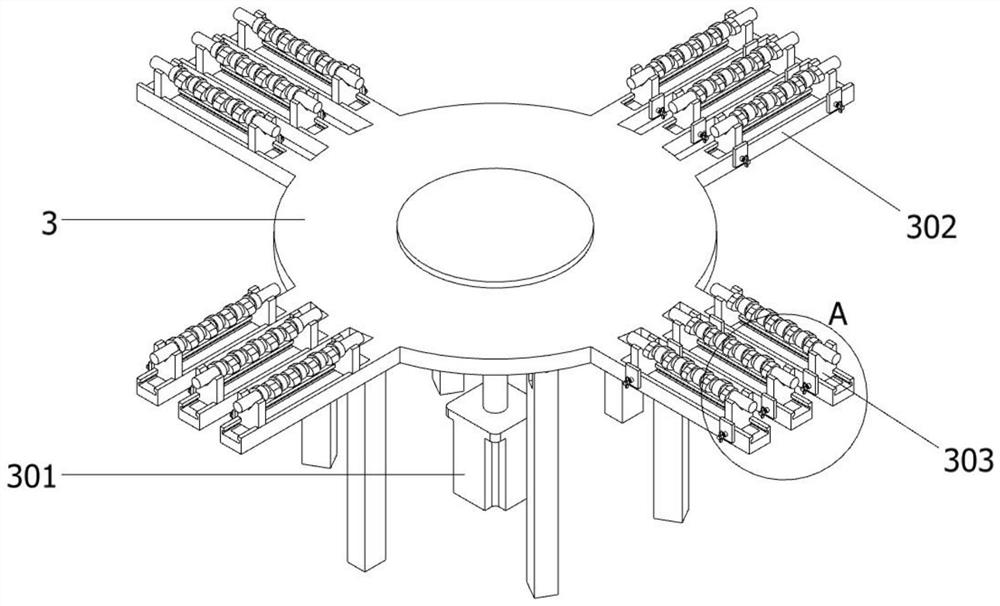

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The present invention provides a special camshaft pre-cleaning equipment, which includes a bottom plate 1, a U-shaped support plate 2 is provided at the rear side edge of the upper end surface of the bottom plate 1, and a rotation drive mechanism 3 is provided at the center of the upper end surface of the bottom plate 1, and the rotation drive mechanism 3 It includes a stepping motor 301, a driving rod 302, a V-shaped support block 303, a fastening bolt 304 and a supporting roller 305. The stepping motor 301 is installed at the center of the upper end surface of the bottom plate 1, and the stepping motor 301 is connected with a rotating drive through a rotating shaft. Mechanism 3, the rotation driving mechanism 3 is a circular plate-shaped structure, and the outer peripheral surface of the rotation driving mechanism 3 is arranged in an annular array with four groups of driving rods 302, and the number of each gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com