Punch forming technology of protective tank for sparkling water machine

A stamping forming and bubble water machine technology, which is applied in the field of foaming machines, can solve the problems of poor structural strength, complex and cumbersome production process of protective tanks, and easy deformation of protective tanks, so as to achieve long service life, good protection effect and improved safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described in conjunction with the following examples.

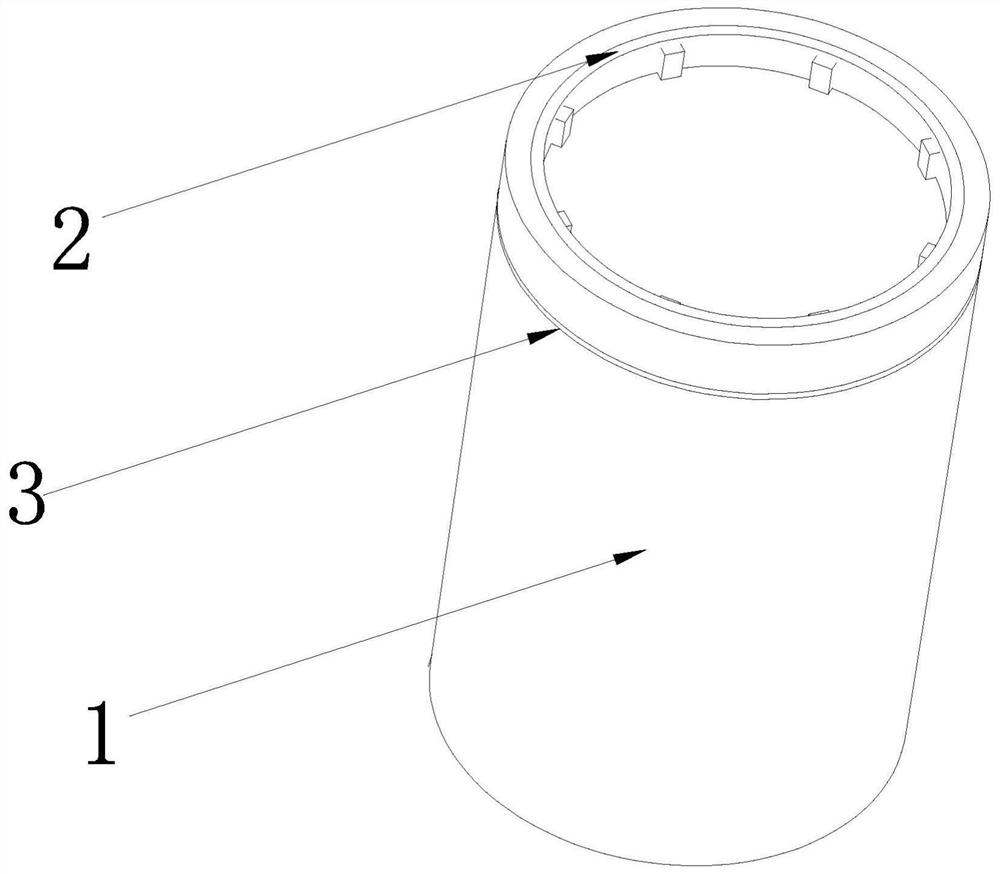

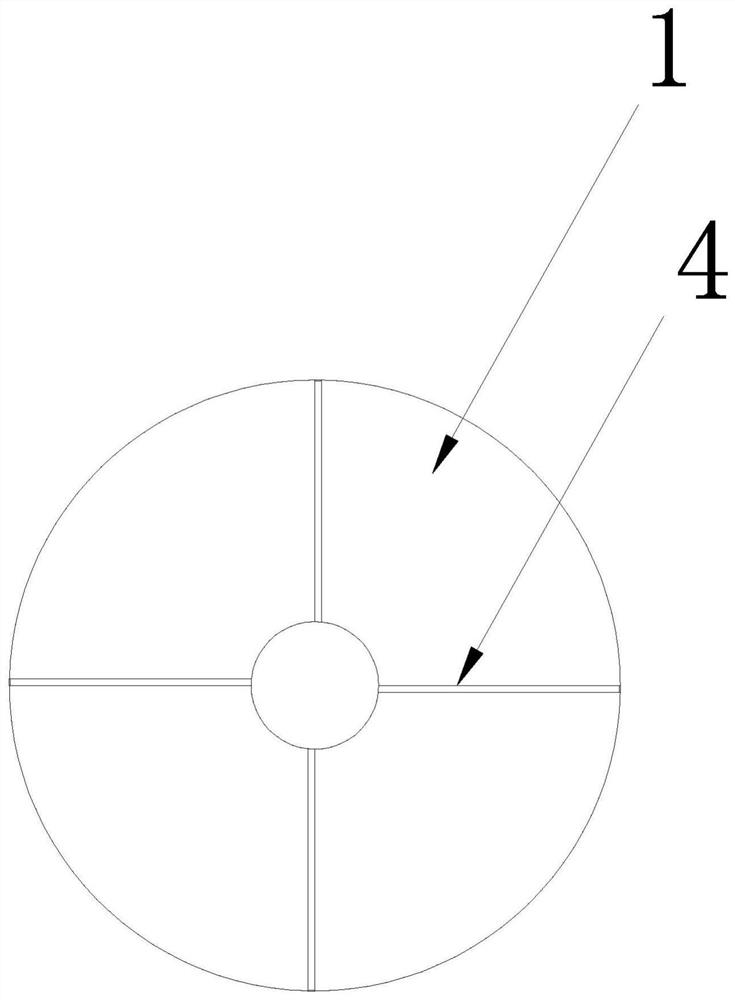

[0020] A specific embodiment of the stamping forming process of a protective tank for a sparkling water machine according to the present invention includes the following steps: step a, cutting the material, selecting a stainless steel plate as a raw material, and cutting out a circular material plate. Specifically, in step a, the selected model is SUS304 / 2B, the thickness of the material plate is 0.6T, and the diameter of the material plate is 293mm. The stainless steel of SUS304 / 2B has good corrosion resistance, heat resistance, low temperature strength and mechanical strength. Good performance, stamping, bending and other hot workability, no heat treatment hardening phenomenon, non-magnetic, suitable for the preparation of protective tanks.

[0021] Step b, oiling, using a pair of cloth wheels to oil the material sheet in step a, the extrusion force between the two cloth wheels is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com