Self-heating power battery system and driving heating method

A driving heating and power battery technology, applied in the automotive field, can solve problems such as complex structure, long heating time of power battery system, lack of solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

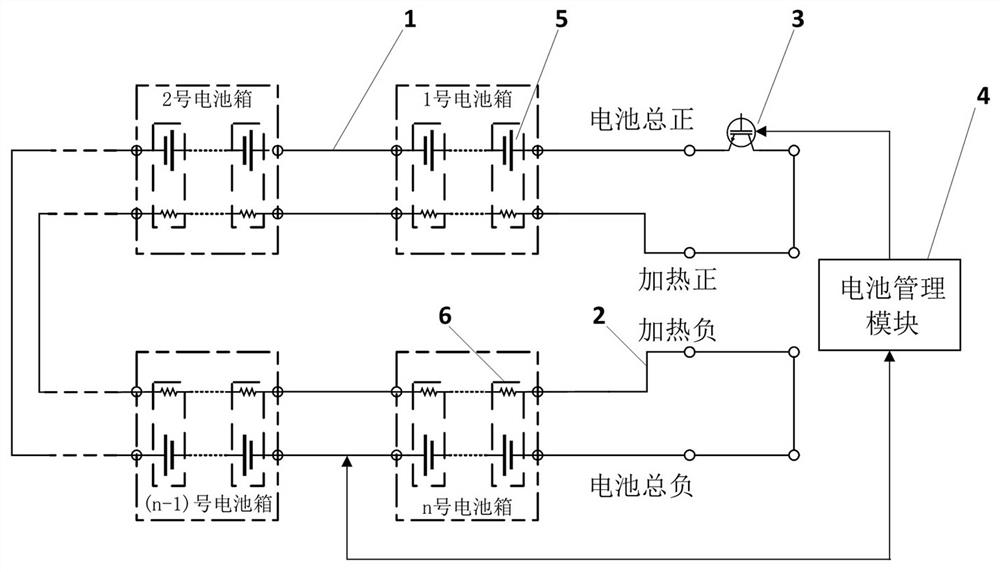

[0124] Such as image 3 As shown, it is a schematic diagram of a circuit connection of the self-heating power battery system of the present invention, including: battery circuit 1, heating circuit 2, switch module 3, battery management module 4, battery circuit 1 and heating circuit 2, switch module 3, The battery management module 4 is connected; the battery cells 5 in the battery circuit 1 are soft-packed lithium-ion batteries made of ternary materials, and the battery cells 5 are connected in series to form a battery module. One piece of heating sheet 6, the heating sheet 6 is made of pure nickel metal sheet, and multiple heating sheets 6 are connected in series and connected to the heating circuit 2.

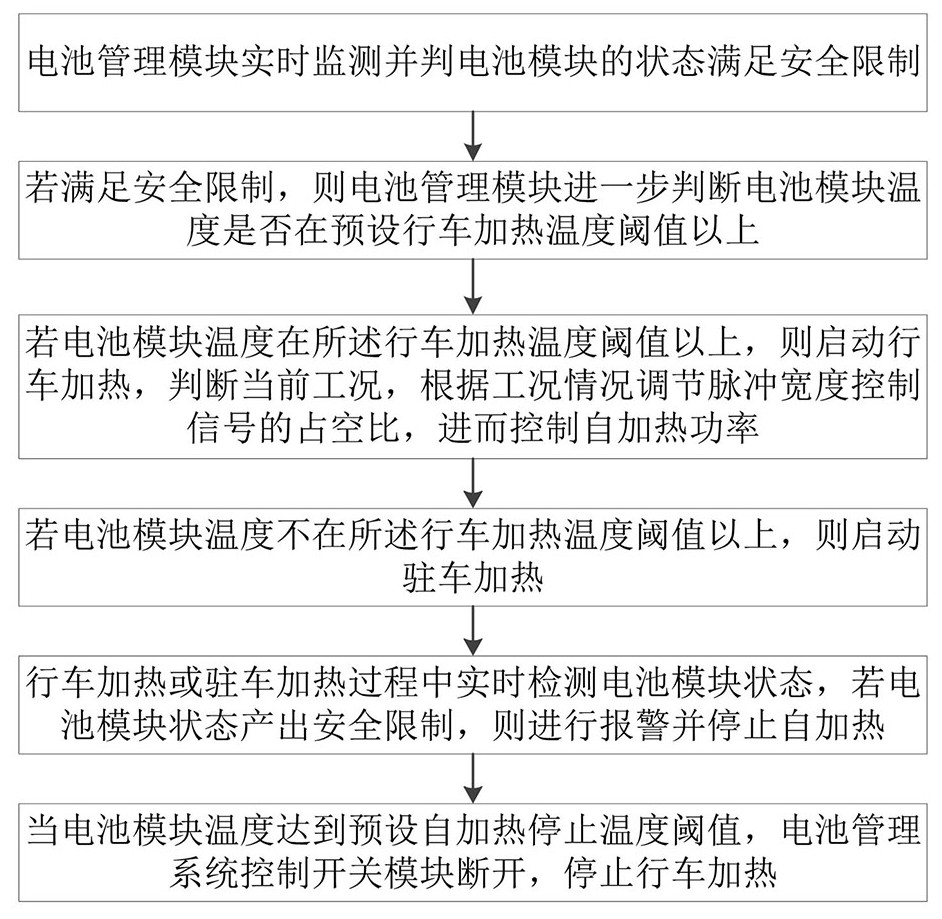

[0125] Driving heating process such as Figure 4 As shown, taking the ambient temperature of -20°C as an example, the initial temperature of the battery module is -20°C, and the safety limit range of the battery cell 5 voltage is 2.75V to 4.25V; the battery module voltage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com