Preparation method of betulinic acid polymer

A technology for betulinic acid and polymers, which is applied in the field of preparing betulinic acid polymers and pentacyclic triterpenoid polymers by using ball mills, and can solve the problems of low contact probability between alcoholic hydroxyl groups and carboxyl groups, complex experimental conditions, etc. , to achieve the effects of low chemical synthesis cost, high application potential, and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

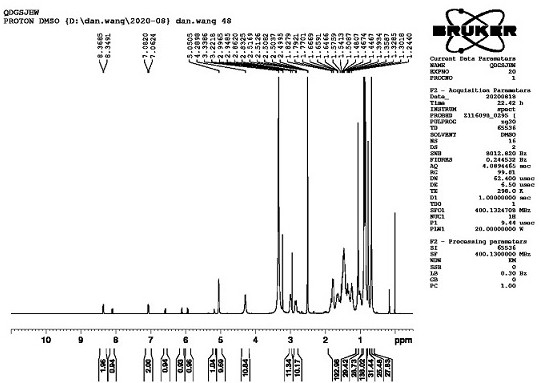

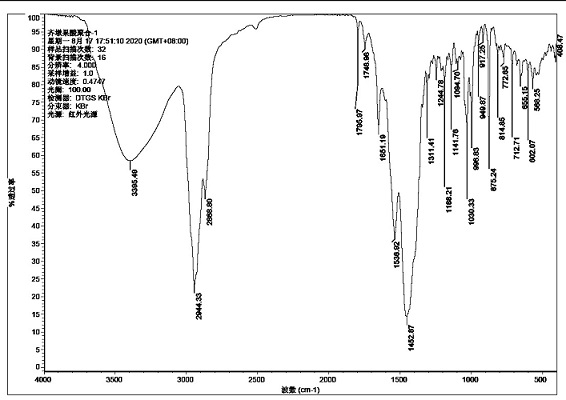

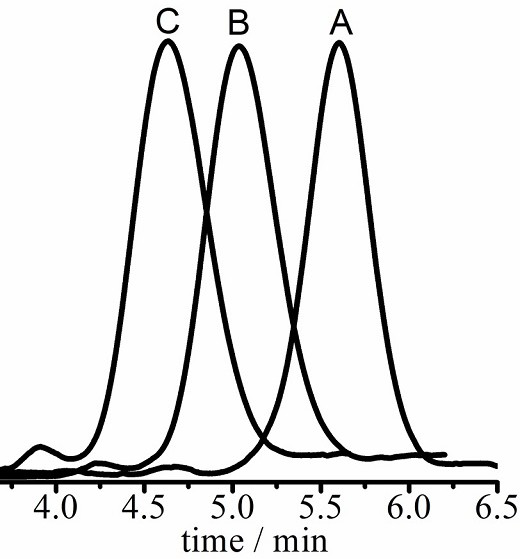

Embodiment 1

[0023] Weigh 4.56 g of betulinic acid, 3.8 µL of ammonium hydroxide, 0.022 g of hydroquinone, and 0.022 g of powdered calcium chloride, put them into a ball mill jar, select 8 agate balls of Φ5 mm, 4 agate balls of Φ 10 mm, and Φ Two 20mm agate balls. Start the ball mill at a speed of 400 r / min. After running for 25 minutes, the ball mill pauses for 5 minutes, and exhausts the pressure once. After 1 hour, that is, after the second suspension of pressure relief, stop the ball mill after running for another 25 minutes. Open the ball mill tank, transfer the solids and agate balls in the tank into 20 mL of acetone, the solids are completely dissolved, and there is no residual solid on the surface of the agate balls, pour the acetone solution into 200 mL of methanol, and a white solid is precipitated, and the white The solid was dried at 45° C. for 4 hours in a forced air drying oven, and the obtained solid was detected by NMR, infrared and gel permeation chromatography.

Embodiment 2

[0025] Weigh 4.56 g of betulinic acid, 85.7 mg of barium hydroxide, 10.4 µL of benzyl alcohol, and 0.011 g of powdered calcium chloride, put them into a ball mill jar, select 8 agate balls of Φ5 mm, 4 agate balls of Φ 10 mm, and Φ 20 mm 2 standard agate balls. Start the ball mill at a speed of 400 r / min. After running for 25 minutes, the ball mill pauses for 5 minutes, and exhausts the pressure once. After 1 hour, that is, after the second suspension of pressure relief, stop the ball mill after running for another 25 minutes. Open the ball mill tank, move the solids and agate balls in the tank into 20 mL of acetone, the solids are completely dissolved, and there is no residual solid on the surface of the agate balls, the acetone solution is poured into 200 mL of methanol, a white solid is precipitated, and the white The solid was dried at 45° C. for 4 hours in a forced air drying oven, and the obtained solid was detected by NMR, infrared and gel permeation chromatography.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap