Tank-entering type coke quenching car

A coke quenching car and coke quenching technology, applied in the field of coke quenching car, can solve the problems of environmental pollution, high equipment investment and operation cost, equipment investment and operation stability can not meet the requirements of coke quenching operation in the coking industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

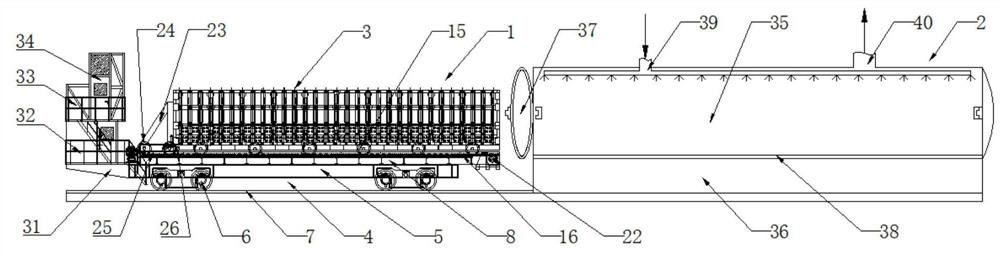

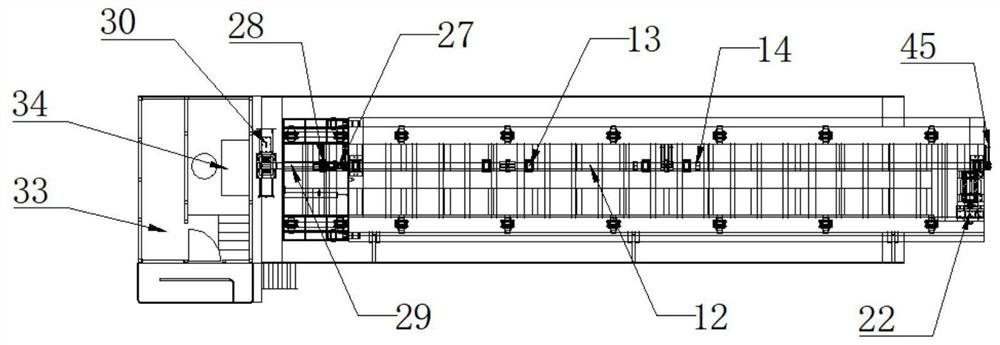

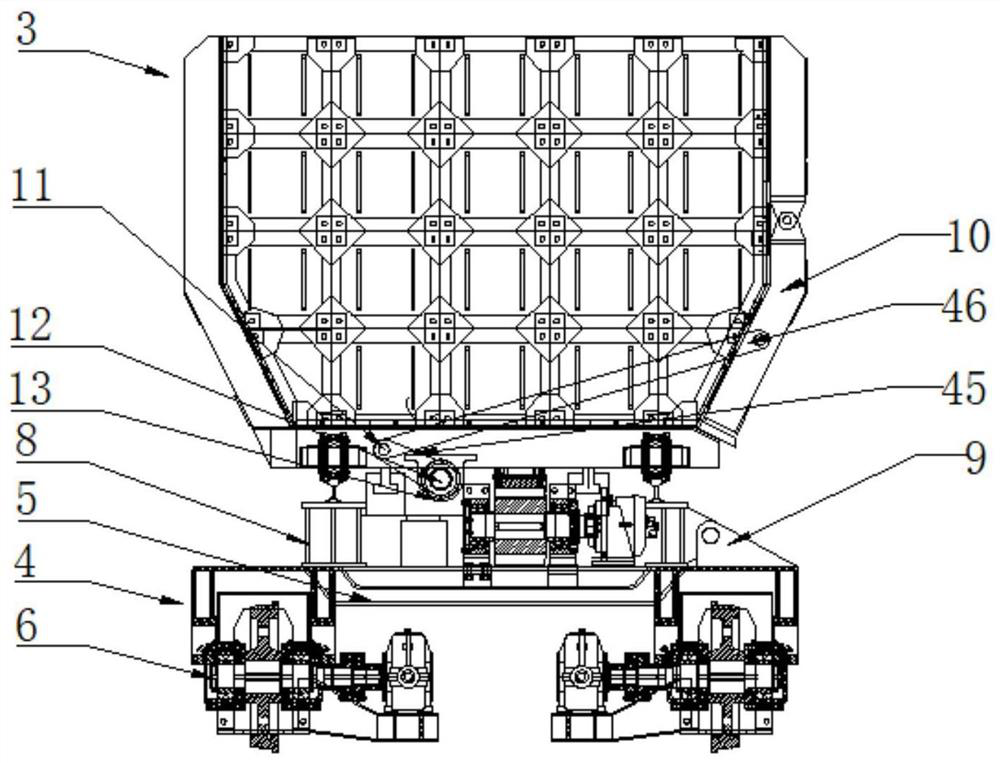

[0037] Such as Figure 1-9 As shown, a tank-entry coke quenching car includes a coke quenching car 1 and a coke quenching tank 2, and the coke quenching car includes a coke quenching tank car 3 for containing red coke and a carrier for carrying the coke quenching tank car The flat car 4, the flat car includes a horizontal load-bearing main frame 5, a track running mechanism 6 is arranged under the load-bearing main frame, a first track 7 is laid under the track running mechanism, and a rollover connecting pair is arranged above the load-bearing main frame Frame 8 is connected to one side of the sub-frame and is hinged to the load-bearing main frame through a hinge 9;

[0038] A coke quenching tank car is arranged above the connecting sub-frame, and the side of the coke quenching tank car close to the hinge is provided with a hinged door 10 that can be turned up and opened, and the bottom of the coke quenching tank car is provided with a crank arm linkage mechanism for controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com