Excavator bucket for engineering construction

A technology for engineering construction and excavators, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., which can solve the problems of failure to achieve better excavation performance, heavy buckets, and high labor costs. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

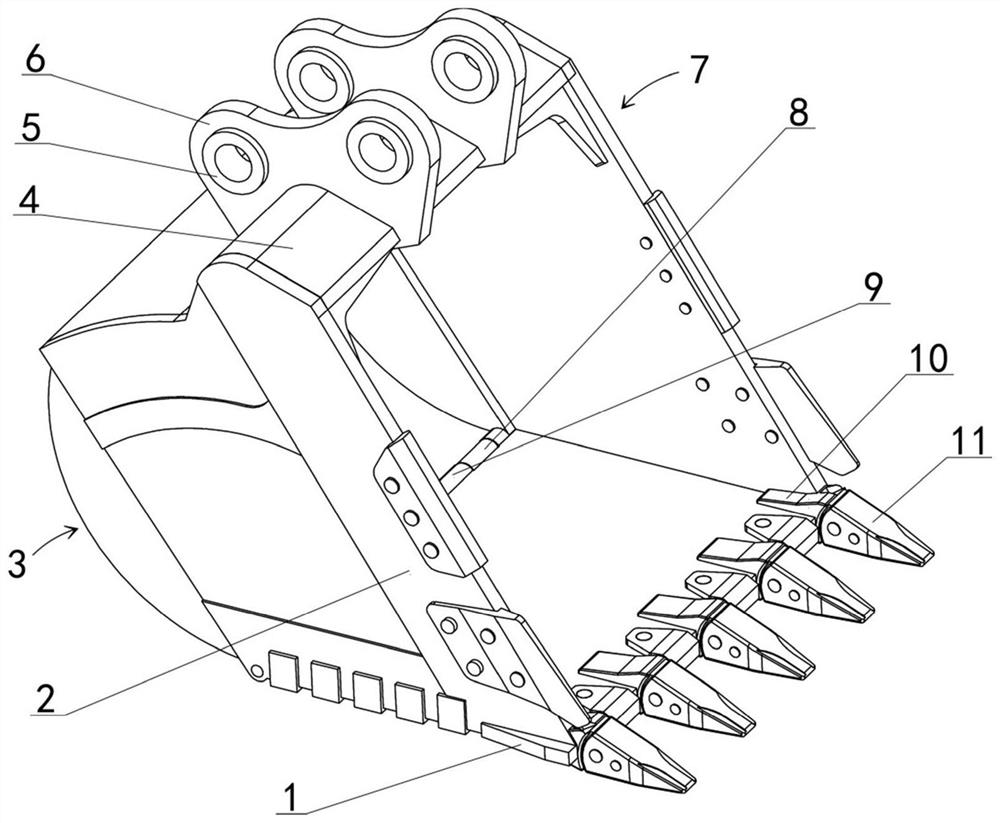

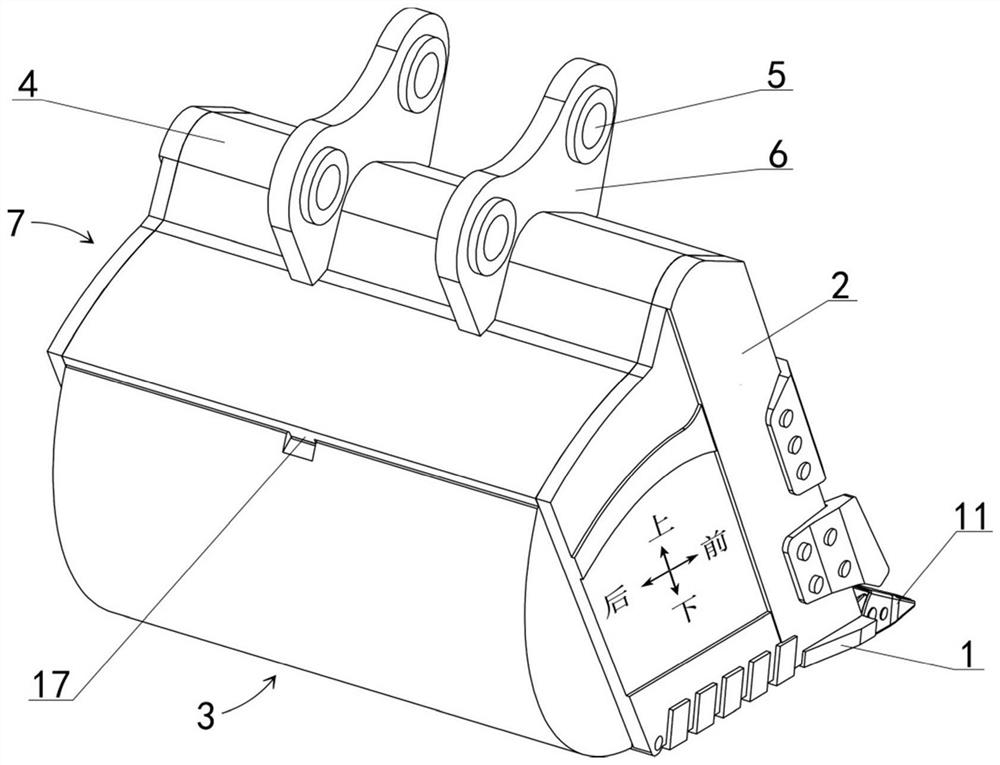

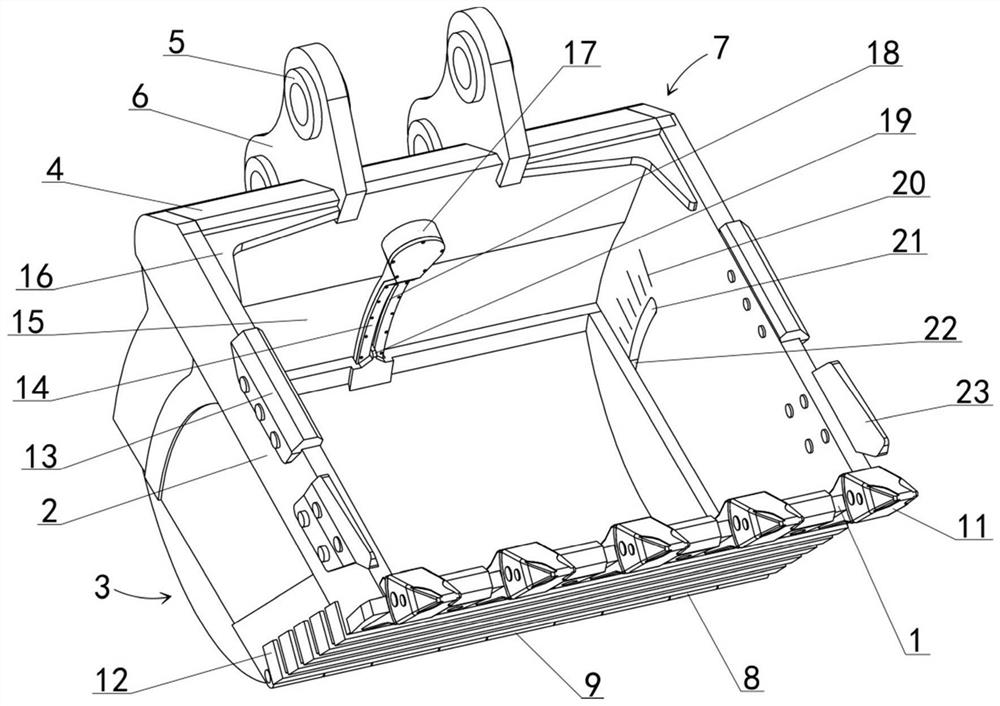

[0025] see Figure 1-5 As shown, the engineering construction excavator bucket disclosed in this embodiment includes a bucket body 7 and a bottom cover 3 arranged at the rear of the bucket body 7; the bucket body 7 has an inner cavity, and the bucket body 7 The rear end is open and is in the shape of a transparent frame. The lower part of the front end of the bucket body 7 is fixed with a tooth seat plate 1, also known as a knife plate. The left and right sides of the bucket body 7 are fixed with side plates 2, also known as side knife plates. 7. The back plate 4 and the ear plate 6 are fixed on the upper side. The rear lower end of the bucket body 7 is provided with a first hinged part 9. The middle rear part of the inner side of the upper wall of the bucket body 7 is arc-shaped, which is called an arc surface 15. The geometric central axes of the arc-shaped surface 15 and the first hinge part 9 coincide and extend along the left and right directions. Bucket teeth 11, the ba...

Embodiment 2

[0047] see image 3 , 8 As shown, in the excavator bucket for engineering construction disclosed in Embodiment 1, a guide groove 18 is opened on the lower side of the part of the rope box 17 located at the arc surface 15, so that the traction part 19 can move with the traction rope 24, usually In other words, when implementing this embodiment, the width of the guide groove 18 is minimized to ensure that the materials in the bucket body 7 will not easily enter the rope box 17 through the guide groove 18 during the operation of the excavator; , when implementing this bucket, a corresponding leak hole can also be opened at the rear end of the rope box 17, so that the materials entering the rope box 17 can be discharged, and the materials in the rope box 17 can be prevented from causing adverse effects on the adjustment function of the bucket capacity. In addition, in order to better solve the above-mentioned problems, the present embodiment carries out the following improvements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com