Prefabricated wallboard of noise reduction protective separation wall

A technology of prefabricated wall panels and protective isolation, applied in the direction of sound insulation, building type, construction, etc., can solve the problems that cannot be reduced or eliminated, and the effect is limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

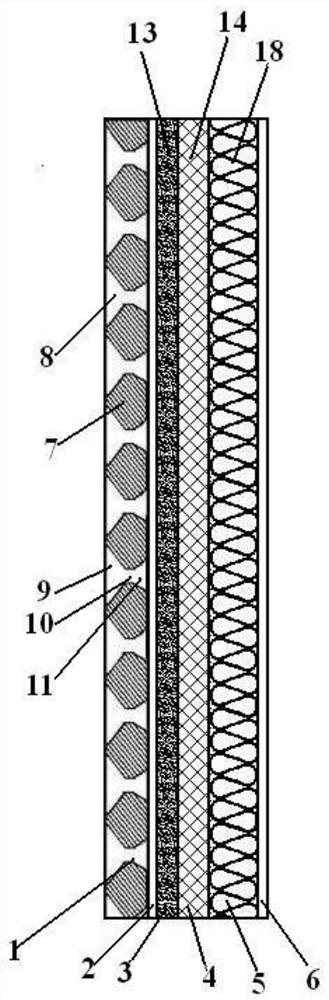

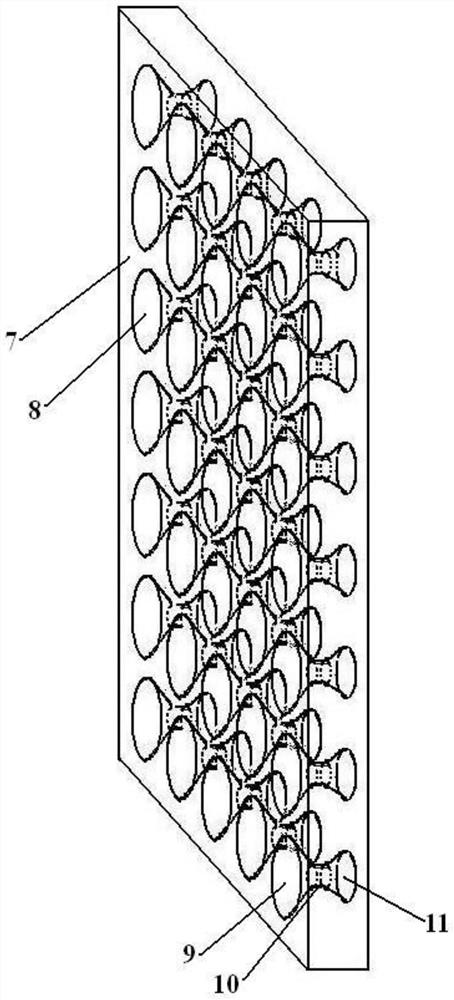

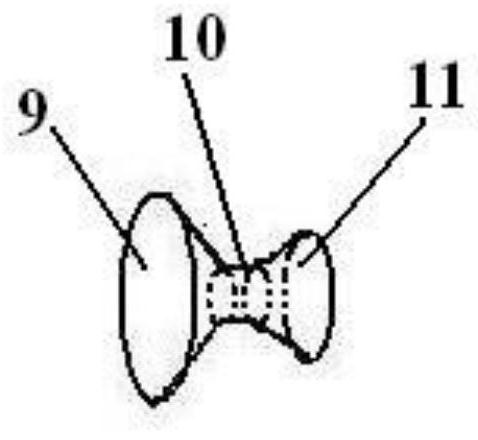

[0039] As shown in the figure, making a prefabricated wall panel for a noise reduction protective partition wall includes the following steps:

[0040] ⑴To make the sound-absorbing board, firstly make the mold of the double-speaker structure hole 8, make a wide-mouth horn as the mold for the wide-mouth horn hole 9, make the outer diameter of the wide-mouth horn 65.5mm, and make the inner diameter 10mm , the inclination of the tube wall is made to be 70°, and the inclination of the tube wall of the horn corresponds to the inclination of the horn wall of 12; and the inner mouth of the wide-mouth horn is made into a screw thread that can be turned; The narrow-mouth horn of the tube is used as the common mold of the straight cylinder hole 10 and the narrow-mouth horn hole 11. The diameter of the straight cylinder is made into 10mm, and the length of the cylinder wall is made into 7mm. The outer thread of 2mm length is matched with the inner thread of the wide-mouthed horn, the out...

Embodiment 2

[0047] As shown in the figure, making a prefabricated wall panel for a noise reduction protective partition wall includes the following steps:

[0048] ⑴To make the sound-absorbing board body, first make a mold for the double-speaker structure hole 8, make a wide-mouth horn as the mold for the wide-mouth horn hole 9, and make the outer diameter of the wide-mouth horn 44.6mm, and the inner diameter 10mm , the inclination of the tube wall is made to be 60°, and the inclination of the tube wall of the horn corresponds to the inclination of the horn wall of 12; and the inner mouth of the wide-mouth horn is made into a screw thread that can be turned; The narrow-mouth horn of the tube is used as the common mold of the straight cylinder hole 10 and the narrow-mouth horn hole 11. The diameter of the straight cylinder is made into 10mm, and the length of the cylinder wall is made into 7mm. 2mm length of the external thread, so that it matches the internal thread of the wide-mouthed ho...

Embodiment 3

[0055] As shown in the figure, making a prefabricated wall panel for a noise reduction protective partition wall includes the following steps:

[0056] ⑴To make the sound-absorbing board body, first make a mold for the double-speaker structure hole 8, make a wide-mouth horn as the mold for the wide-mouth horn hole 9, and make the outer diameter of the wide-mouth horn 38.6mm, and the inner diameter 10mm , the inclination of the tube wall is made to be 55°, the inclination of the tube wall of the horn corresponds to the inclination of the horn wall 12; and the inner mouth of the wide-mouth horn is made into a screw thread that can be turned; The narrow-mouth horn of the tube is used as the common mold of the straight cylinder hole 10 and the narrow-mouth horn hole 11. The diameter of the straight cylinder is made into 10mm, and the length of the cylinder wall is made into 7mm. 2mm length of the external thread, so that it matches the internal thread of the wide-mouthed horn, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com