Layered energy storage system capable of supplying steam at constant temperature for molten salt

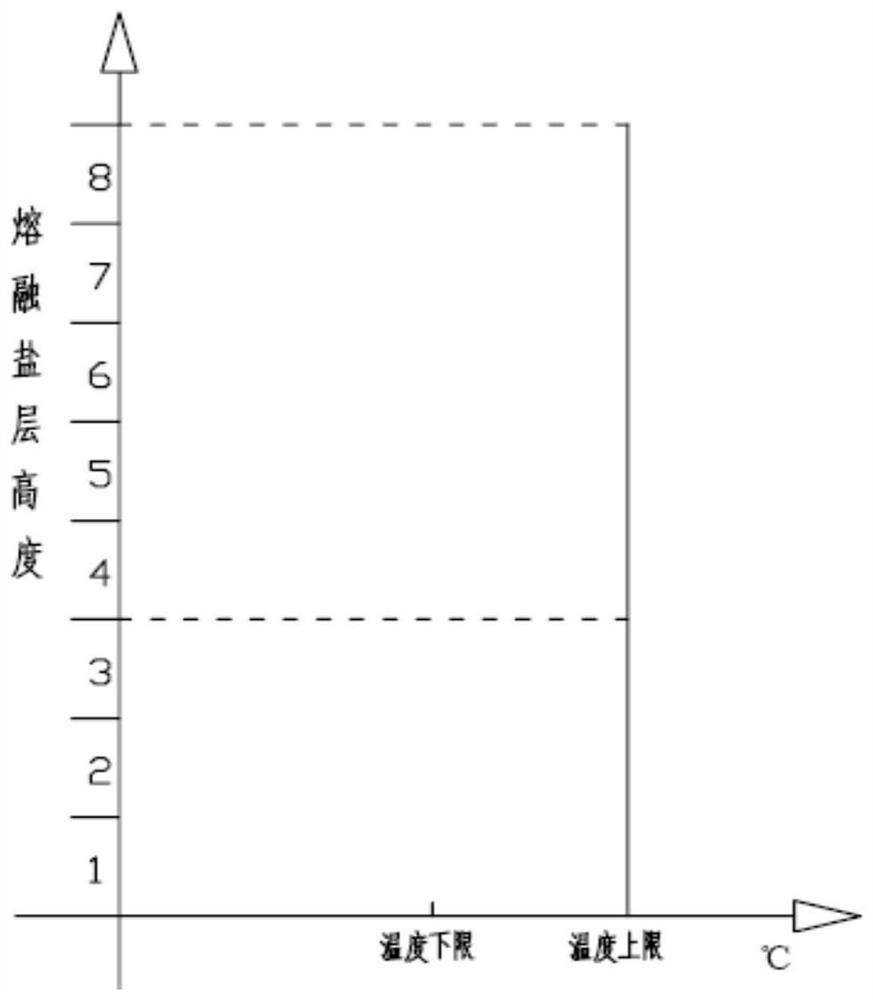

An energy storage system and salt technology, which is applied in the control/regulation system, temperature control, temperature control by electric means, etc., can solve the working temperature range of compressed molten salt, the low steam outlet temperature cannot meet the production demand, and reduce the storage capacity. heat capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

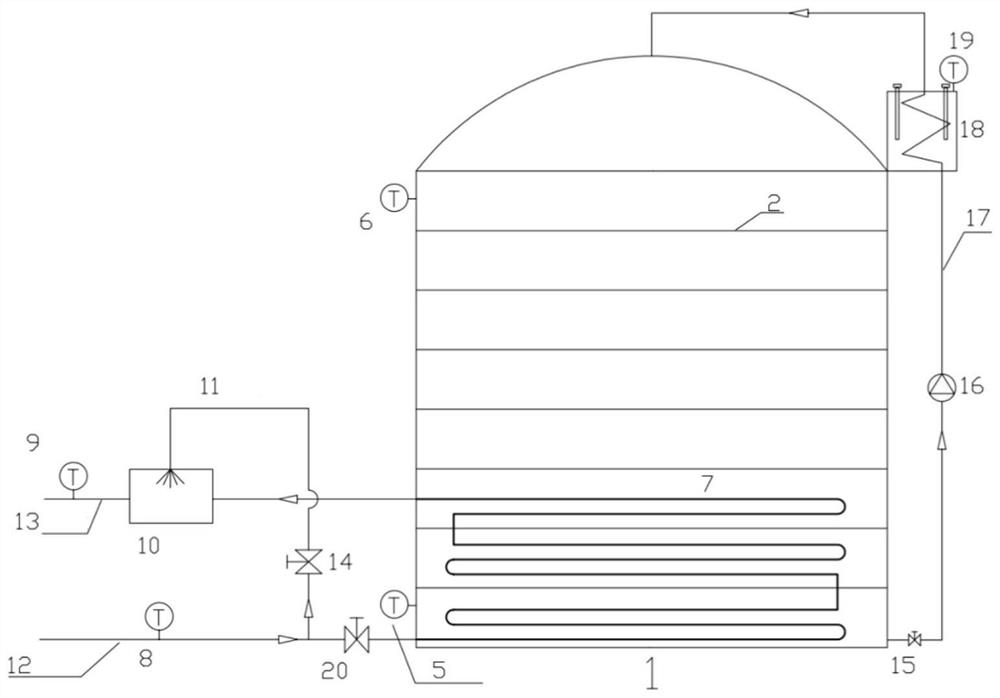

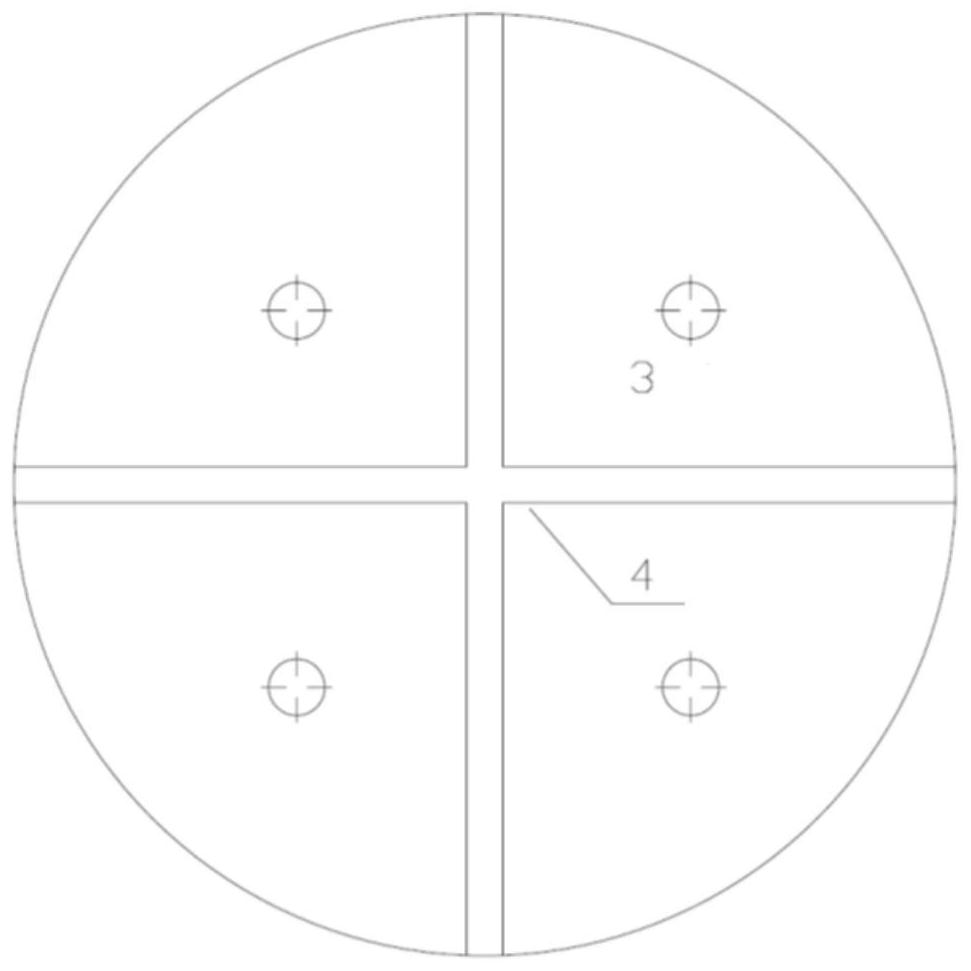

[0022] refer to Figure 1 to Figure 2 , the molten salt stratified energy storage system capable of supplying steam at a constant temperature according to the present invention includes a heat storage tank 1, a heater 7, a water inlet pipeline 12, a desuperheating water pipeline 11, a water spray desuperheater 10, a steam pipeline 13, a circulation Pump 16 and electric heating furnace 18; heat storage tank 1 is provided with a number of partition plates 2 from top to bottom, wherein overflow holes 3 are opened on each partition plate 2, and the heater 7 includes several sequentially connected Heat exchange tubes, wherein each heat exchange tube is located between the adjacent partition plates 2 at the bottom of the heat storage tank 1, and the outlet of the water inlet pipe 12 is divided into two paths, one of which communicates with the inlet of the heater 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com