Oil congelation prevention type transformer oil tank for extremely cold region

A technology for transformer oil tanks and regions, which is applied in the field of oil-freeze-proof transformer oil tanks, which can solve problems such as increasing the kinetic energy of insulating oil, and achieve the effects of maintaining fluidity, reducing freezing, and effectively cooling down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

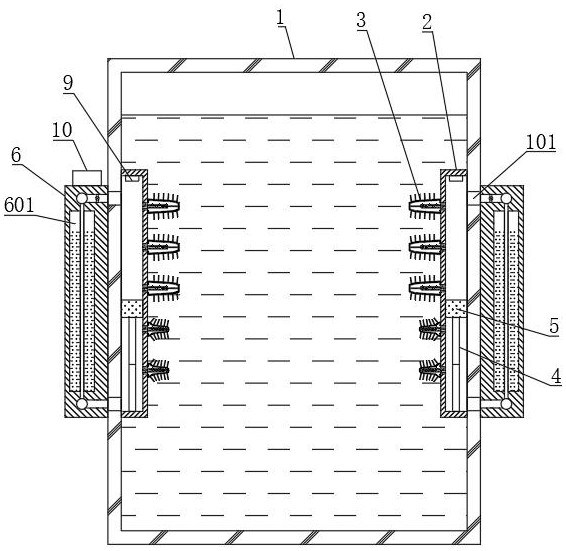

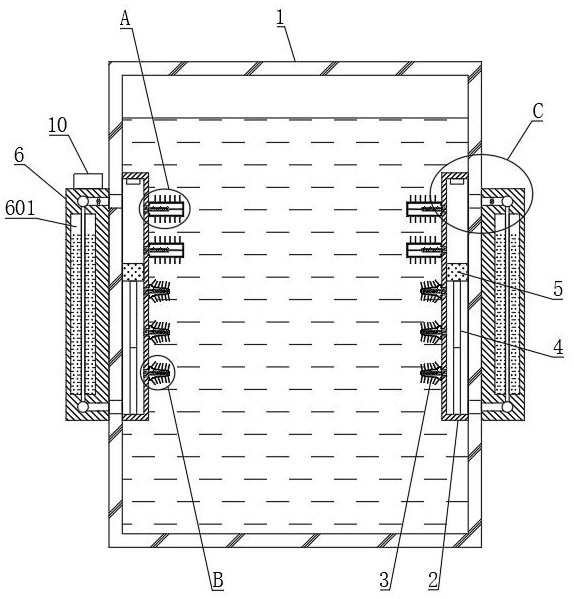

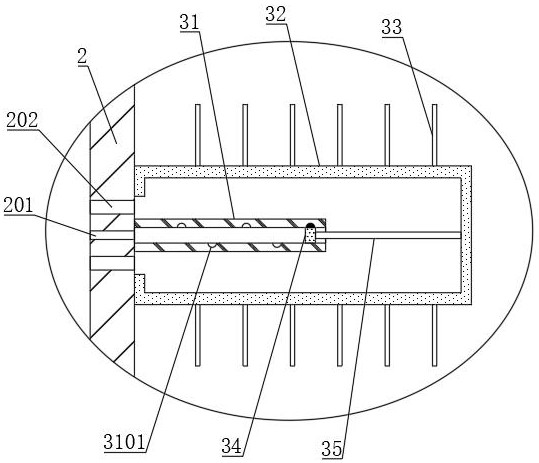

[0036] see figure 1 , an anti-oil freeze-type transformer oil tank used in extremely cold regions, including a tank 1 with insulating oil inside, the inner wall of the tank 1 is fixedly connected with a semi-open back-shaped frame 2, and the semi-open back-shaped frame 2 is far away from the tank One end of the body 1 is fixedly connected with a plurality of evenly distributed deformed flow-stirring needle capsules 3, please refer to image 3 with Figure 4 The deformed flow-stirring needle capsule 3 includes an inner cylinder 31 and a telescopic capsule 32, the inner cylinder 31 is located inside the telescopic capsule 32, and one end of the inner cylinder 31 and the telescopic capsule 32 is fixedly connected to the outer end of the semi-open circular frame 2, The telescoping bag 32 is made of high-temperature-resistant high-elastic material. The semi-open circular frame 2 is provided with a plurality of secondary airflow holes 201 corresponding to the inner cylinder 31 one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com