Wide-angle broadband frequency selective surface

A frequency selective surface, large angle technology, applied in electrical components, circuits, antennas, etc., can solve the problems of large passband insertion loss, inhibition deterioration, etc., and achieve the effect of low cost, large application potential, and mature processing and preparation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

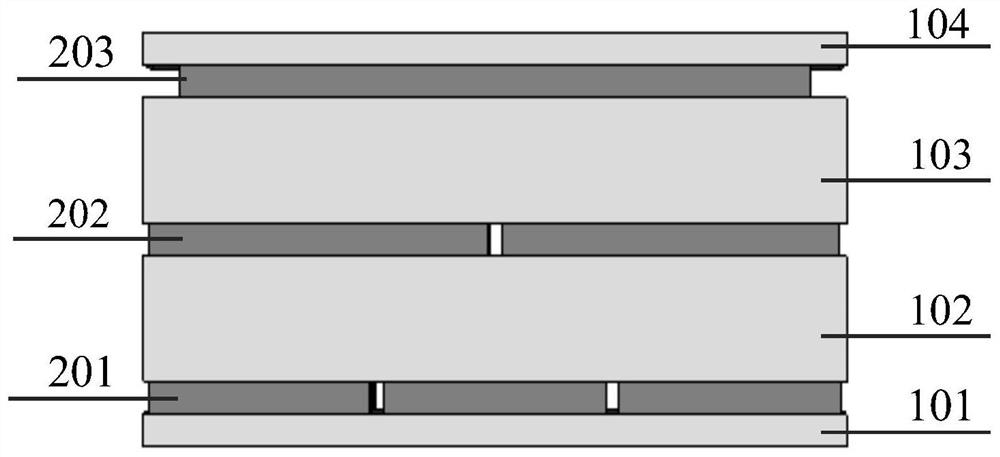

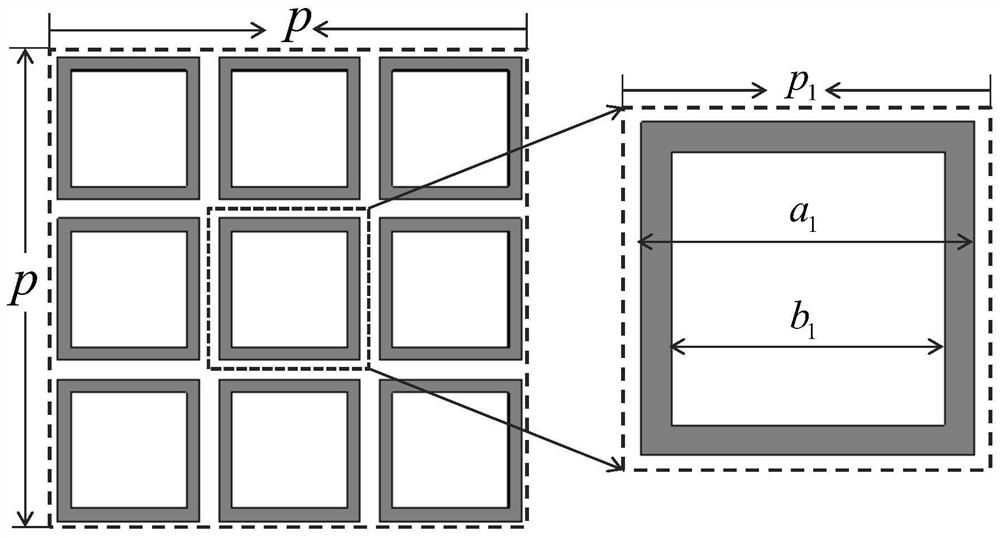

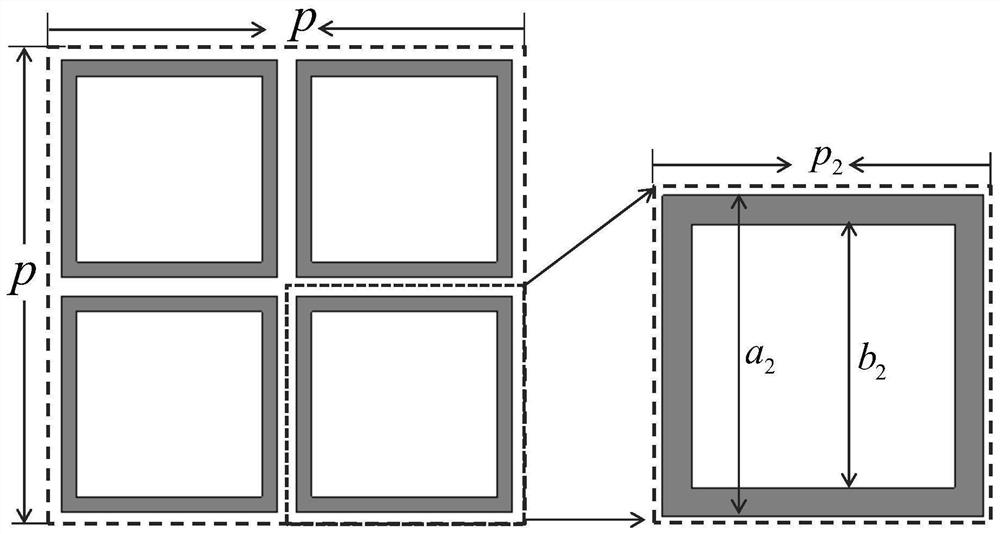

[0032] The present invention provides a large-angle broadband frequency selective surface, specifically as figure 1 As shown, it includes a first dielectric substrate 101, a first metal structure array layer 201, a second dielectric substrate 102, a second metal structure array layer 202, a third dielectric substrate 103, and a third metal structure array stacked in sequence from bottom to top. layer 203 and fourth dielectric substrate 104;

[0033] The first metal structure array layer 201 , the second metal structure array layer 202 and the third metal structure array layer 203 are all formed by periodic arrangement of discrete metal patches.

[0034] Further, in this embodiment, the first dielectric substrate 101, the second dielectric substrate 102, the third dielectric substrate 103, and the fourth dielectric substrate 104 are all epoxy resin-based glass fiber cloth (FR4), and epoxy resin-based glass fiber The relative permittivity of the cloth is 4.3.

[0035] Further,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com