Intelligent battery repair pulse charging all-in-one machine and method

A technology of pulse charging and intelligent battery, which is applied in the direction of battery circuit device, battery load switching, charging maintenance charging/discharging, etc. It can solve the problems of shortened battery life, reduced battery capacity, disorder, etc., to prolong the service life and maintain capacity constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

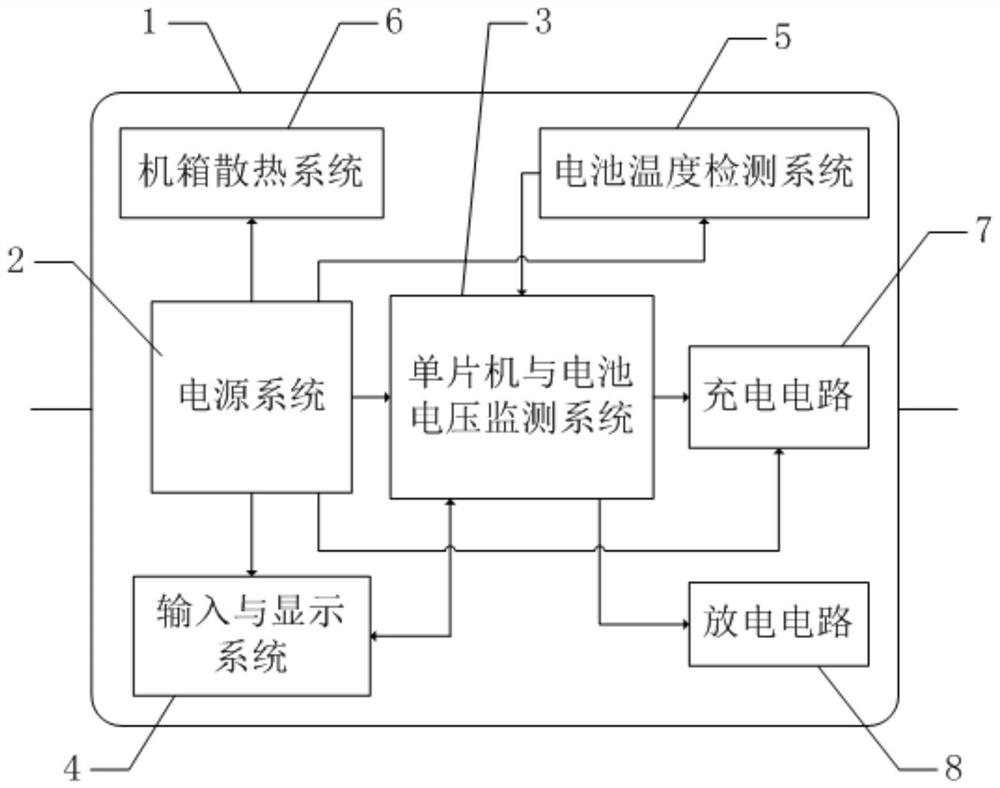

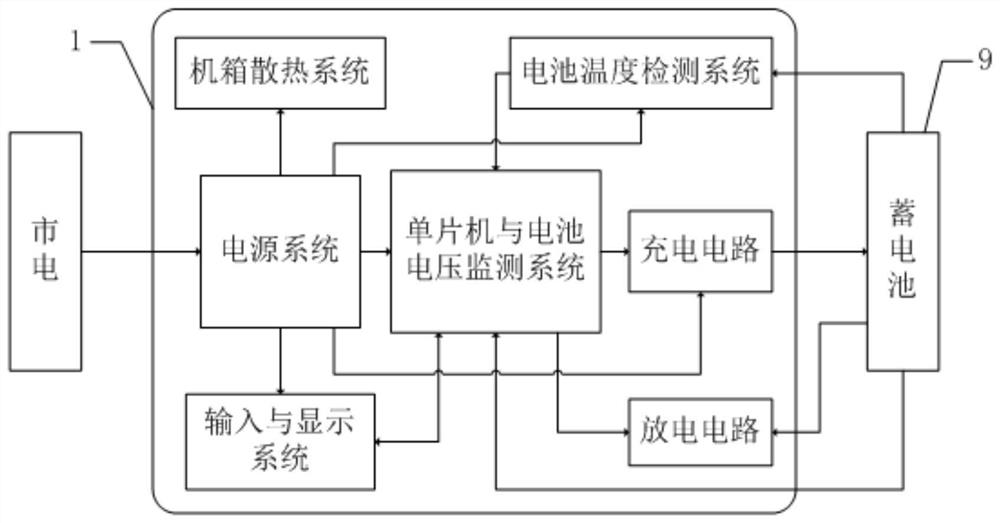

[0033] Embodiment 1: an intelligent battery repair pulse charging integrated machine, including: a local machine 1, the local machine 1 is provided with an interface connected to the mains and an interface connected to the storage battery 9,

[0034] The machine 1 is equipped with a power supply system 2, a single-chip microcomputer and a battery voltage monitoring system 3, an input and display system 4, a battery temperature detection system 5, a chassis heat dissipation system 6, a charging circuit 7 and a discharging circuit 8, all of which are used for power supply The power supply system 2 is respectively connected with the single-chip microcomputer and the battery voltage monitoring system 3, the input and display system 4, the battery temperature detection system 5, the chassis heat dissipation system 6 and the charging circuit 7, for controlling The single-chip microcomputer establishes signal connection with the battery voltage monitoring system 3 and the battery temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com