Rear-mounted ditcher soil dividing wing

A trencher, rear-mounted technology, which is applied in the field of soil separation wings, can solve the problems of soil accumulation in hard corners, soil blocks can not be spread evenly from near to far, and difficult to manufacture soil separation wings, etc., and achieves wear-resistant adhesion. Soil, reducing adhesion to soil or even clogging the trencher, the effect of not easily adhering to soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail in conjunction with embodiment now.

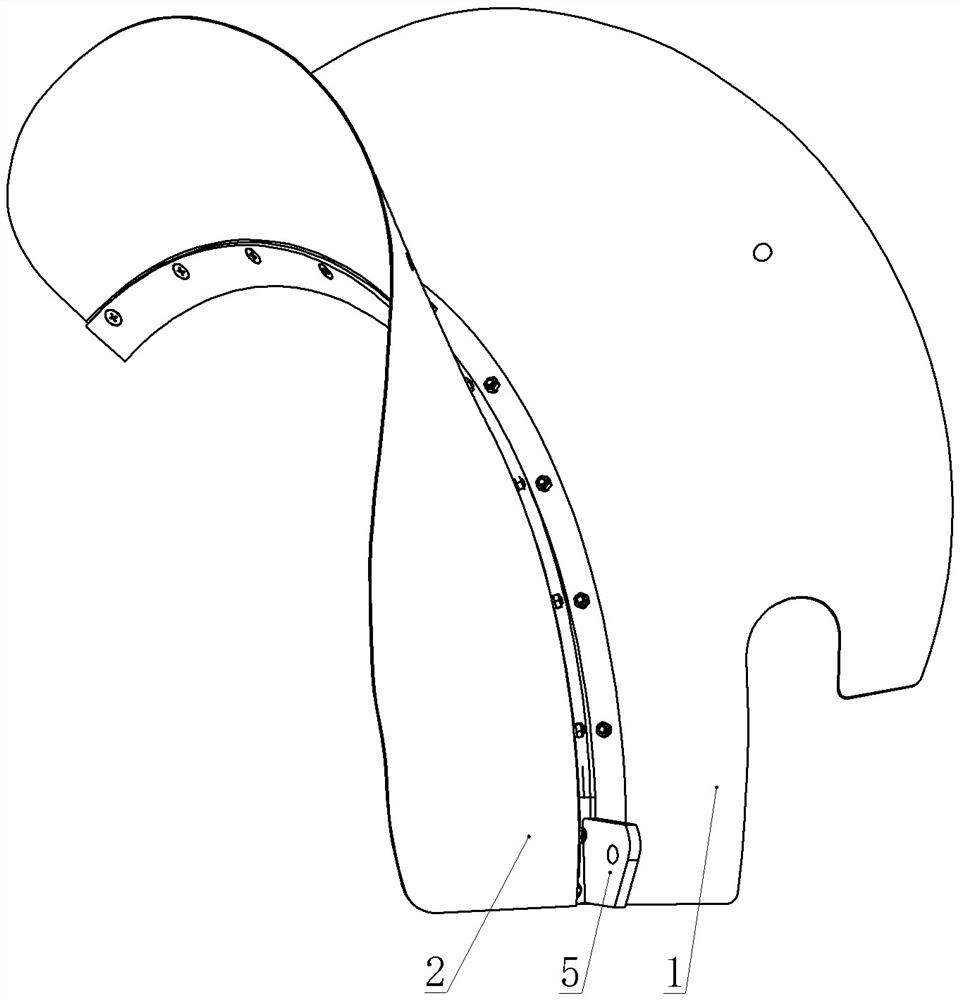

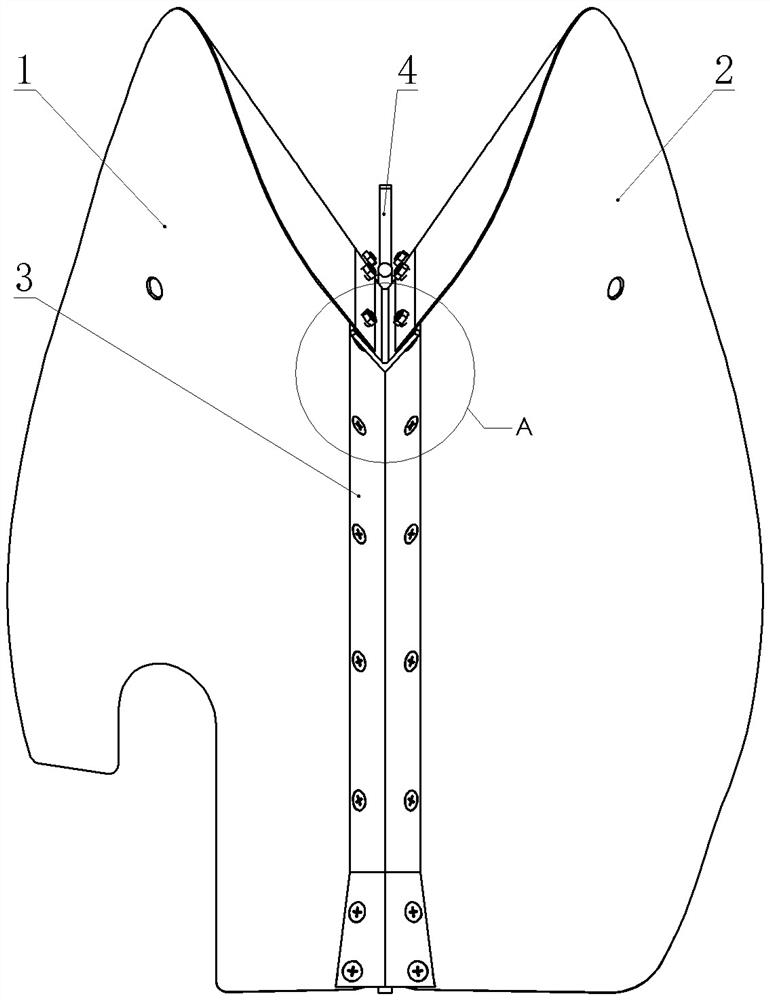

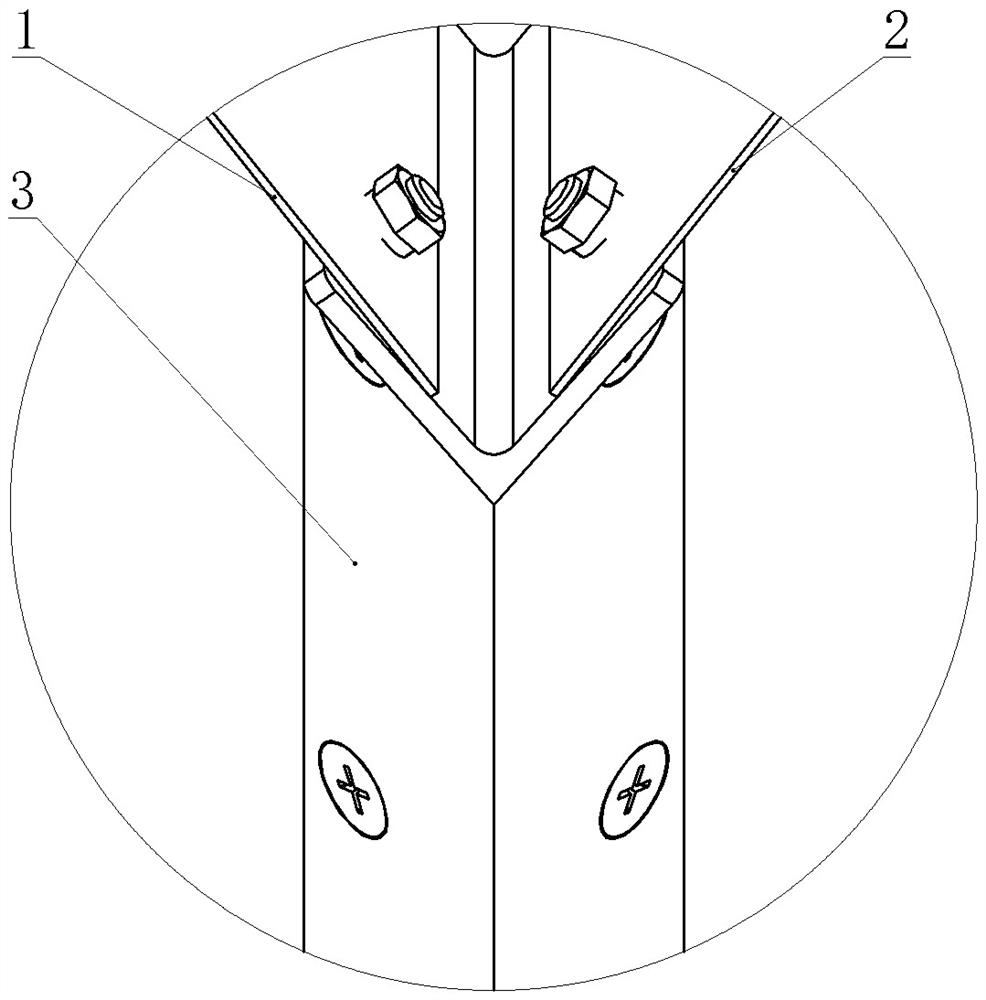

[0020] Such as Figure 1 to Figure 5 As shown, the present invention discloses a rear-mounted ditching machine soil-distributing wing. The soil-dividing wing is composed of two left-wing plates 1 and right-wing plates 2 whose upper and lower edges are arc-shaped, and one bent into a cross-section of V It is composed of arc-shaped bow beam 3 viewed from the axial direction of the cutter head. There are several through holes evenly arranged at the junction of the lower edge of the left wing plate 1 and the right wing plate 2 and the bow beam 3, which are assembled with bolts or riveted with rivets. Above the inner side of the V-shaped bow beam 3 . The used bolt is a countersunk head, and the lower part of the V-shaped outer side of the bow beam 3 is processed with a countersunk hole corresponding to the bolt, which can also be riveted with a countersunk rivet.

[0021] Such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com