Infusion filter and production equipment and method thereof

A technology for producing equipment and filters, which is applied to filter accessories, devices introduced into the body, and manufacturing tools, etc., can solve the problems of low assembly efficiency, low feeding efficiency, difficult production speed, etc., to improve production efficiency and feeding efficiency. The effect of high, simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

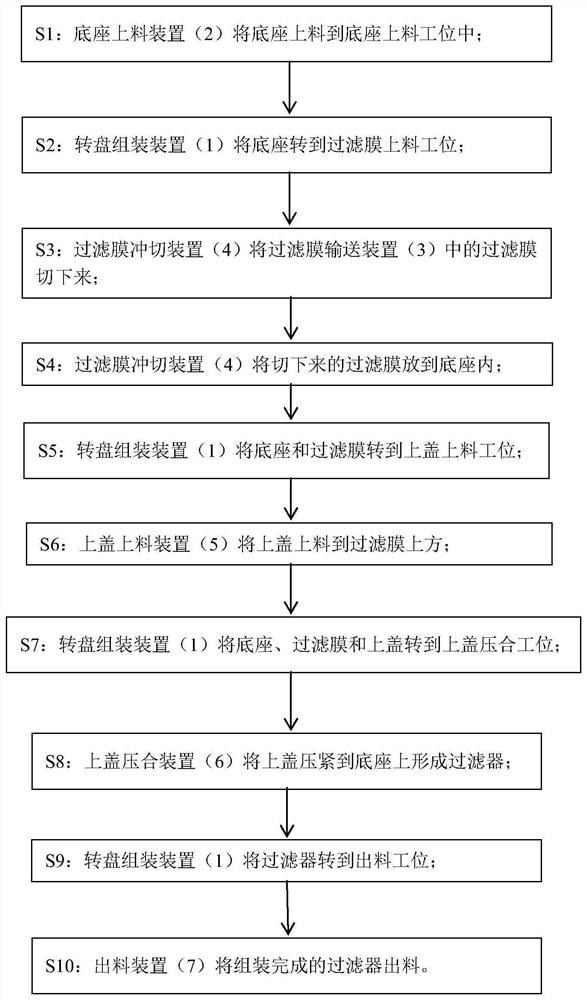

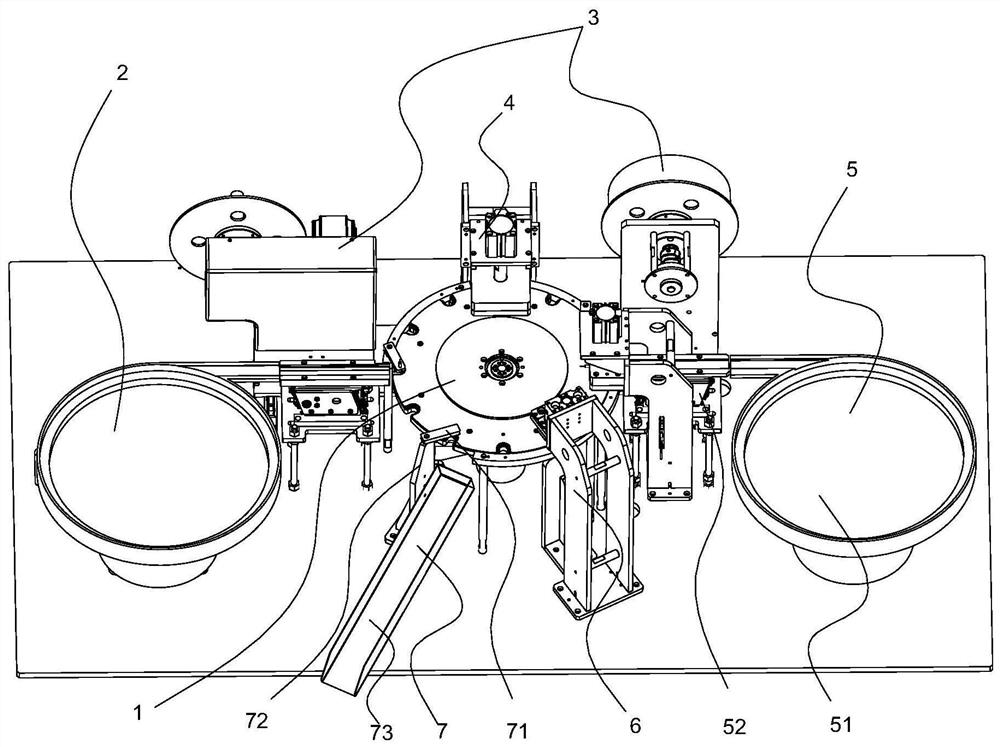

[0046] Such as figure 2 As shown, an infusion filter production equipment includes a frame and a turntable assembly device 1 installed on the frame, a lower cover feeding device 2, a filter membrane conveying device 3, a filter membrane punching device 4, and an upper cover feeding device Device 5, upper cover pressing device 6 and discharge device 7; turntable assembly device 1 is provided with lower cover feeding station, filter membrane feeding station, upper cover feeding station, and upper cover pressing station in sequence and the discharge station; the position of the lower cover feeding device 2 is matched with the lower cover feeding station; the position of the filter membrane conveying device 3 is matched with the filter membrane feeding station, and the middle part of the filter membrane conveying device 3 is connected with the filter membrane punch The cutting device 4; the position of the upper cover feeding device 5 matches the upper cover feeding station; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com