Mold assembling process for small motor shell sand mold and mold assembling tool

A technology of small motors and groups, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators. It can solve the problems of inconvenient operation and achieve the effects of simple production, sand mold protection, dimensional accuracy and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

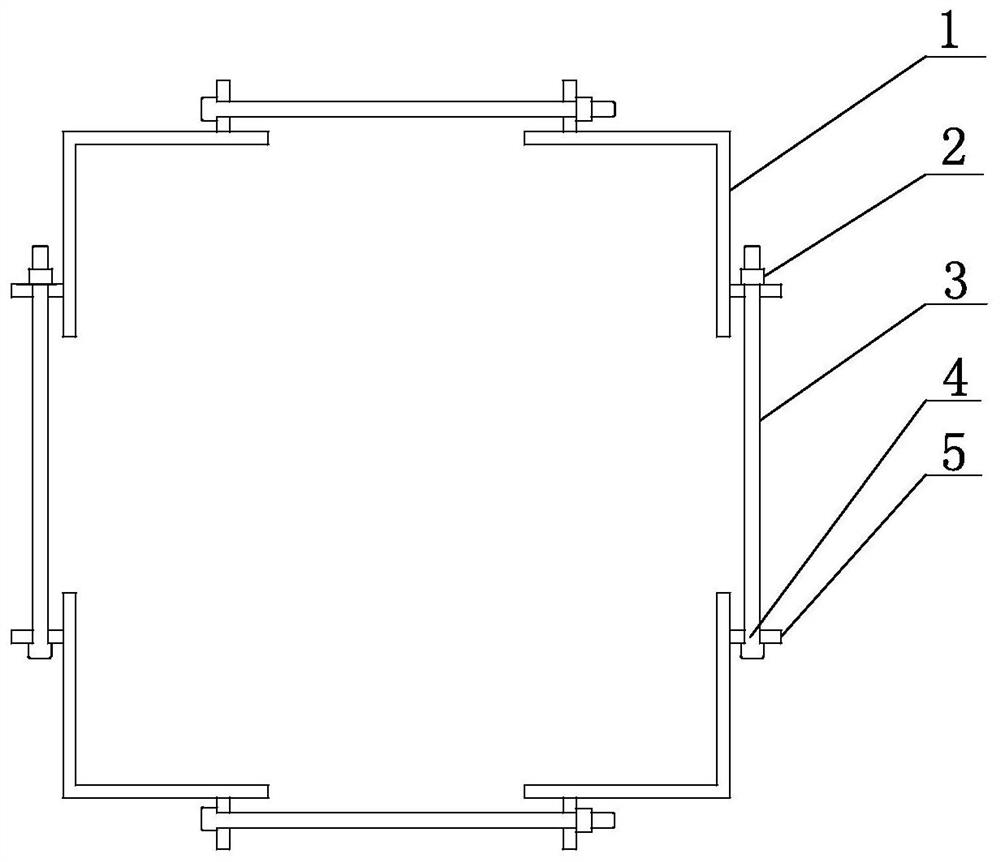

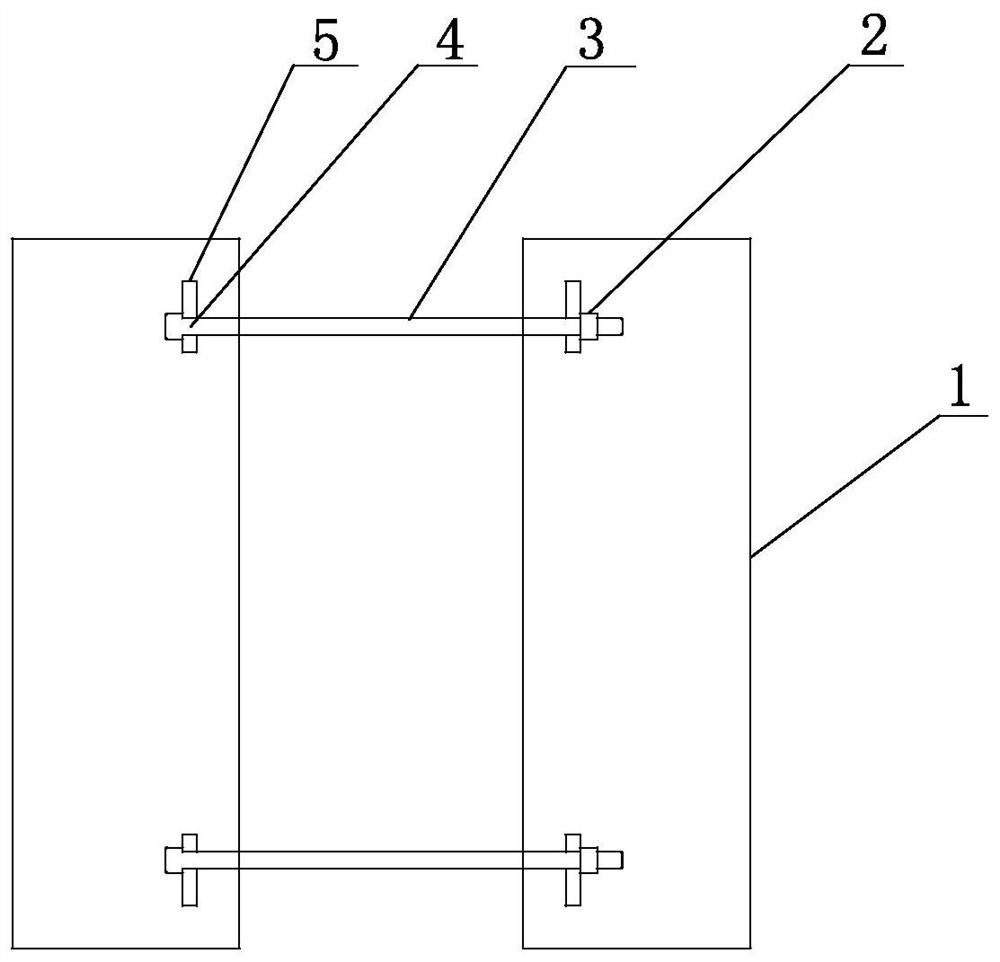

[0032] Such as Figure 1-2 As shown, the small-sized motor casing sand molding tooling of the present invention includes a fixed angle iron 1, a fastening bolt 3 and a fastening nut 2, and the outer surface of the fixed angle iron 1 is fixedly connected with a fixed plate 5, and the fixed Fastening holes 4 are provided on the plate 5 .

[0033] The fixed angle iron 1 is formed by welding two iron plates at right angles, and the height of the fixed angle iron 1 is the same as that of the sand mold.

[0034] The upper and lower ends of the outer surface of the iron plate of the fixed angle iron 1 are respectively welded with fixed plates 5 .

[0035] The number of fixed angle irons 1 is four, arranged in a rectangular or square distribution.

[0036] The fastening bolts 3 pass through the fastening holes 4 to fix the two adjacent fixed angle irons 1 .

[0037] Adjust the length of the fastening bolt 3 according to the size of the sand mold.

[0038] The material steel plates...

Embodiment 2

[0040] Adopt the small-sized motor case sand molding process of the assembly tooling of embodiment 1, the steps are as follows:

[0041] (1) Add furan resin accounting for 1% of the mass of the original sand and a curing agent accounting for 40% of the mass of the furan resin to the original sand, mix it in a sand mixer, fill it into a mold for curing, and obtain a sand mold;

[0042] (2) After the sand mold is flow-coated with alcohol-based graphite paint, assemble it according to the process, place the assembled sand mold in the middle of the four fixed angle irons, and pass the fastening bolts through the fastening holes of the two adjacent fixed angle irons, fastened in place by the fastening nut;

[0043] (3) After the fastened sand mold is melted and cast, it is poured into fire to obtain a sand casting mold for a small motor casing.

[0044] The molding process is simple to operate, the sand core is fixed and stable during the sand molding molding process, and the dime...

Embodiment 3

[0046] Adopt the small-sized motor case sand molding process of the assembly tooling of embodiment 1, the steps are as follows:

[0047] (1) Add furan resin accounting for 1.1% of the mass of the original sand and a curing agent accounting for 60% of the mass of the furan resin to the original sand, mix it in a sand mixer, fill it into a mold for curing, and obtain a sand mold;

[0048] (2) After the sand mold is flow-coated with alcohol-based graphite paint, assemble it according to the process, place the assembled sand mold in the middle of the four fixed angle irons, and pass the fastening bolts through the fastening holes of the two adjacent fixed angle irons, fastened in place by the fastening nut;

[0049] (3) After the fastened sand mold is melted and cast, it is poured into fire to obtain a sand casting mold for a small motor casing.

[0050] The molding process is simple to operate, the sand core is fixed and stable during the sand molding molding process, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com