Method for solving scaling of cathode of electro-catalytic biological aerated filter

An aerated biological filter and electrocatalysis technology, which are applied in the fields of electrochemical biological combined treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of insufficient backwash strength, uneven air distribution, and poor water flow. and other problems, to achieve the effect of no secondary pollution risk, cost reduction, and speed up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

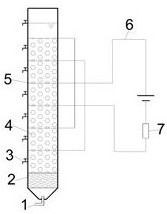

[0024] as attached figure 1 The vertically arranged electrocatalytic biological filter shown in the figure: the sewage water enters from the water inlet (1), flows upward through the support layer (2) and then enters the main part of the electrocatalytic biological aerated filter: granular biological filter material ( 4) Under the action of the electrode plate (5), each micro-electrode can effectively improve the removal rate of refractory biodegradable organic matter. However, in the process of backwashing, due to scaling on the cathode plate, water distribution and gas distribution are often uneven, and the backwashing intensity in local areas is too large, often causing hysteresis in water distribution. The strength far exceeds the design strength, while the distribution of water and air in other areas has obvious hysteresis and the strength is extremely uneven. Using the backwashing method proposed by the present invention, the current commutator (7) is used to exchange t...

Embodiment example 2

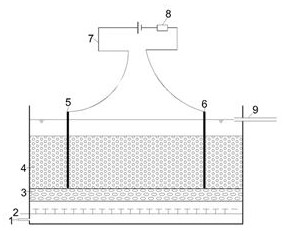

[0026] as attached figure 2 The horizontally arranged electrocatalytic biofilter shown: sewage water enters from the water inlet (1), and the water inlet is accompanied by an aeration device (2), and flows upward through the supporting layer (3) before entering the electrocatalytic aeration The main part of the gas biological filter: the granular biological filter material (4) becomes micro-electrodes under the action of the electrode plate (5) (6), which effectively improves the removal rate of refractory biodegradable organic matter. However, in the process of backwashing, fouling on the cathode plate leads to blockage of the reactor, low current efficiency, and hardening of the particle electrode. Using the backwashing method proposed by the present invention, the current commutator (8) is used to exchange the cathode and anode during backwashing, and the reactor is air-washed for 5-8 minutes; gas-water combined washing is 7-10 minutes; water washing is 8-10 minutes , and...

Embodiment example 3

[0028] as attached image 3 And attached Figure 4 The ring-shaped enlarged anode electrocatalytic biofilter is shown, and the top view of the reactor is shown in the attached Figure 4 Shown: Sewage and waste water enters from the water inlet (1), accompanied by an aeration device (2), flows upwards through the supporting layer (3) and then enters the electrocatalytic biological aerated filter. The main part: granular organisms The filter material (4) becomes microelectrodes under the action of the electrode plates (5) (6), which effectively improves the removal rate of refractory biodegradable organic matter. However, during the backwashing process, the scale on the central cathode column leads to excessive deposition to the bottom of the reactor, resulting in problems such as reactor blockage, low current efficiency, particle electrode compaction, and mixed bed of the support layer and the filter layer. Using the backwashing method proposed by the present invention, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com