Gelled sand gravel and preparation method thereof

A technology for cementing sand and gravel and sand and gravel, which is applied in the field of cemented sand and gravel and its preparation, and achieves the effects of excellent impermeability and freezing resistance, good structure tightness and good arrangement tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

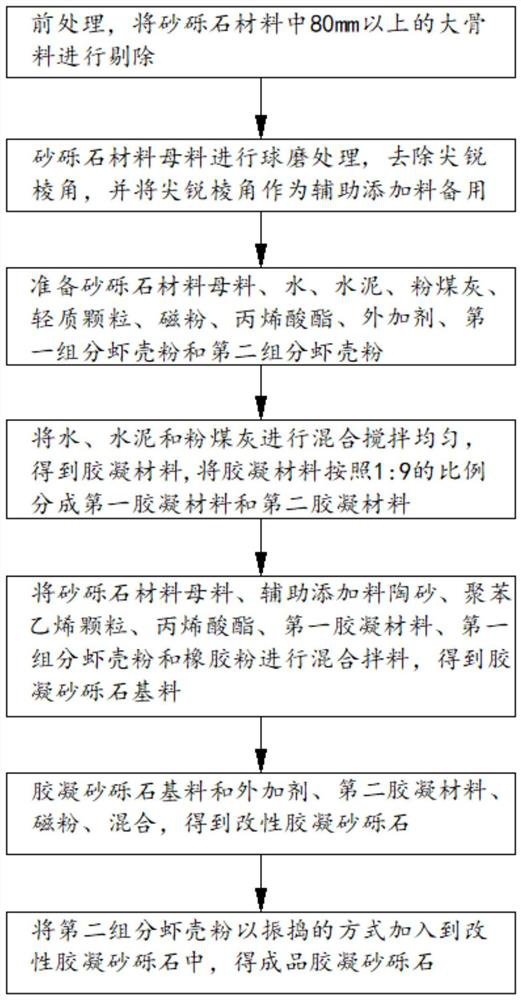

[0032] according to figure 1 As shown, the present embodiment proposes a preparation method of cemented sand and gravel, comprising the following steps:

[0033] 1) Pre-treatment, remove large aggregates of more than 80mm in the sand and gravel materials at the construction site, and at the same time remove plastics, branches, large mud and other non-stone material debris mixed in the sand and gravel materials, and the remaining as a masterbatch;

[0034] 2) The masterbatch is processed by ball milling to remove the sharp edges and corners of the masterbatch, and the masterbatch with sharp edges and corners is collected as auxiliary additives for subsequent use;

[0035] 3) Material preparation: Prepare the following materials in parts by weight: 1000 parts of masterbatch, 100 parts of water, 80 parts of cement, 70 parts of fly ash, 300 parts of light particles, 120 parts of magnetic powder, 100 parts of acrylate, 10 parts of admixture , 150 parts of the first component of s...

Embodiment 2

[0041] according to figure 1 As shown, the present embodiment proposes a preparation method of cemented sand and gravel, comprising the following steps:

[0042] 1) Pre-treatment, remove large aggregates of more than 80mm in the sand and gravel materials at the construction site, and at the same time remove plastics, branches, large mud and other non-stone material debris mixed in the sand and gravel materials, and the remaining as a masterbatch;

[0043] 2) The masterbatch is processed by ball milling to remove the sharp edges and corners of the masterbatch, and the masterbatch with sharp edges and corners is collected as auxiliary additives for subsequent use;

[0044] 3) Material preparation: Prepare the following materials in parts by weight: 1300 parts of masterbatch, 115 parts of water, 100 parts of cement, 100 parts of fly ash, 350 parts of light particles, 130 parts of magnetic powder, 110 parts of acrylate, 15 parts of admixture , 165 parts of the first component of...

Embodiment 3

[0050] according to figure 1 As shown, the present embodiment proposes a preparation method of cemented sand and gravel, comprising the following steps:

[0051] 1) Pre-treatment, remove large aggregates of more than 80mm in the sand and gravel materials at the construction site, and at the same time remove plastics, branches, large mud and other non-stone material debris mixed in the sand and gravel materials, and the remaining as a masterbatch;

[0052] 2) The masterbatch is processed by ball milling to remove the sharp edges and corners of the masterbatch, and the masterbatch with sharp edges and corners is collected as auxiliary additives for subsequent use;

[0053] 3) Material preparation: Prepare the following materials in parts by weight: 1500 parts of masterbatch, 130 parts of water, 130 parts of cement, 130 parts of fly ash, 400 parts of light particles, 140 parts of magnetic powder, 100-120 parts of acrylate, 20 parts Admixture, 180 parts of the first component of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com