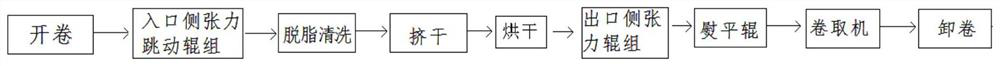

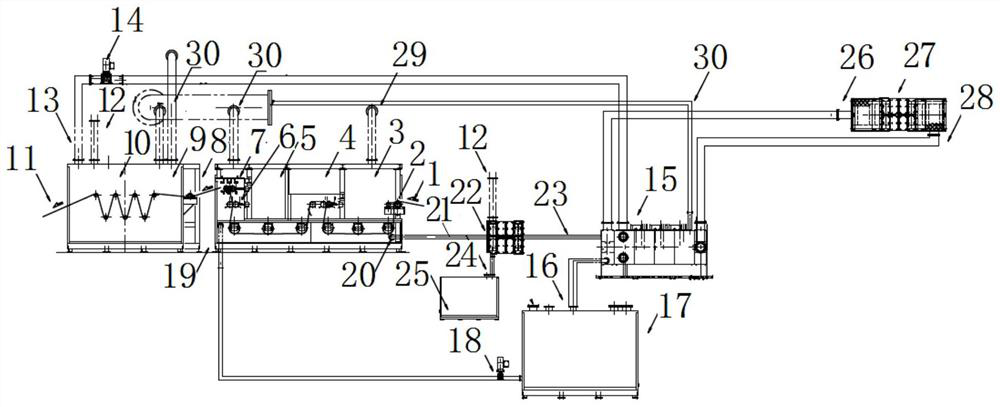

Copper strip foil degreasing cleaning line

A degreasing cleaning and copper strip technology, applied in the field of copper strip processing, can solve the problems of increased cost and environmental protection pressure, large loss of degreasing agent, small tension adjustment margin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

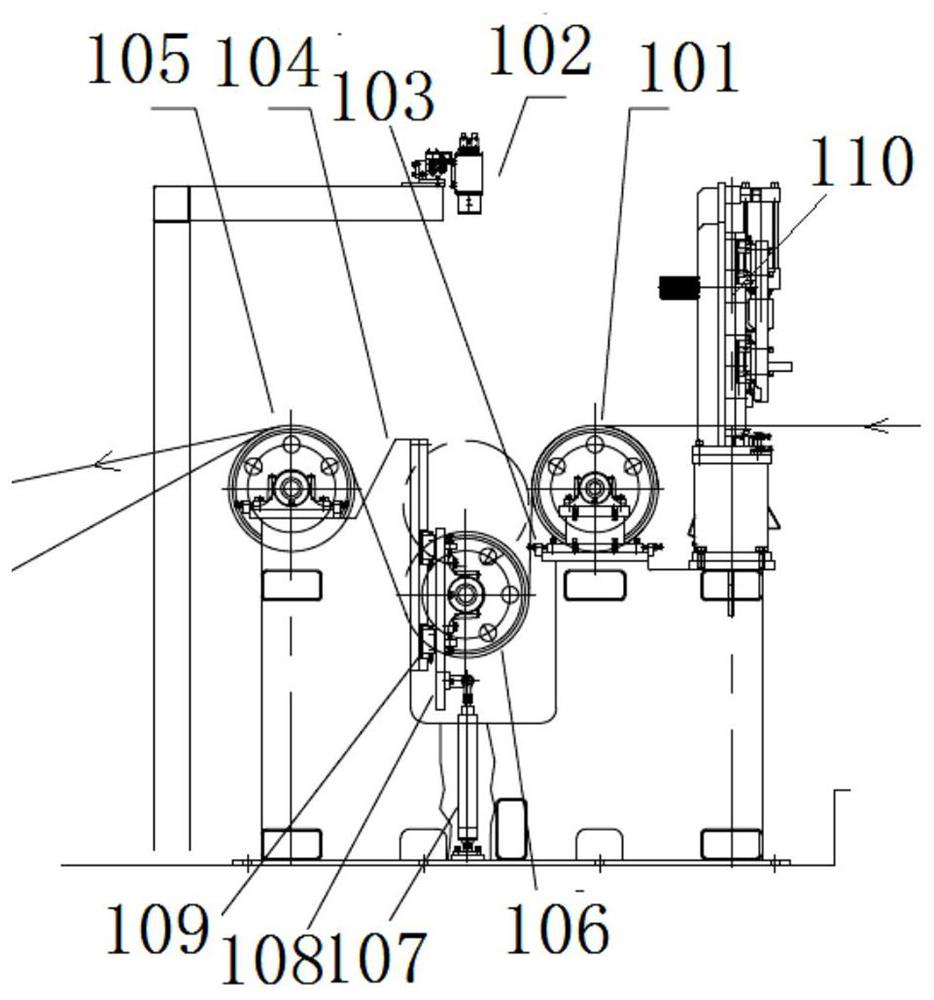

[0064] The non-woven fabric vacuum squeeze roller assembly 201 includes a hollow roller core, a perforated spacer and a non-woven fabric located outside the roller core, an intermediate retaining ring 203 compresses and fixes the non-woven cotton core 207, and the inner retaining ring 205 The holed spacer 206 is fixed, and finally the outer fastening nut 204 is qualitatively fastened. In consideration of preventing back loosening, the position is fixed by the outer locking nut positioning pin 209 .

[0065] The vacuum suction passes through the mandrel hole 208, and is drawn out from the vacuum suction hole 210 through the vacuum suction through hole 211. The vacuum suction power comes from a very mature Roots blower.

[0066] After the suction device with the Roots blower as the vacuum source is started, a negative pressure is formed in the shaft core. When the strip passes through the roll surface, due to the capillary characteristics of the non-woven fabric on the roll surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com