Full-automatic lubricating device for steel wire rope of feeding main winch of blast furnace

A main hoist and lubricating device technology, which is applied in the direction of engine lubrication, metering device, lubricating parts, etc., can solve the problems of high labor intensity, high risk of high-altitude operation, and low application efficiency, so as to prolong the service life and reduce operation Risk and labor intensity, the effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

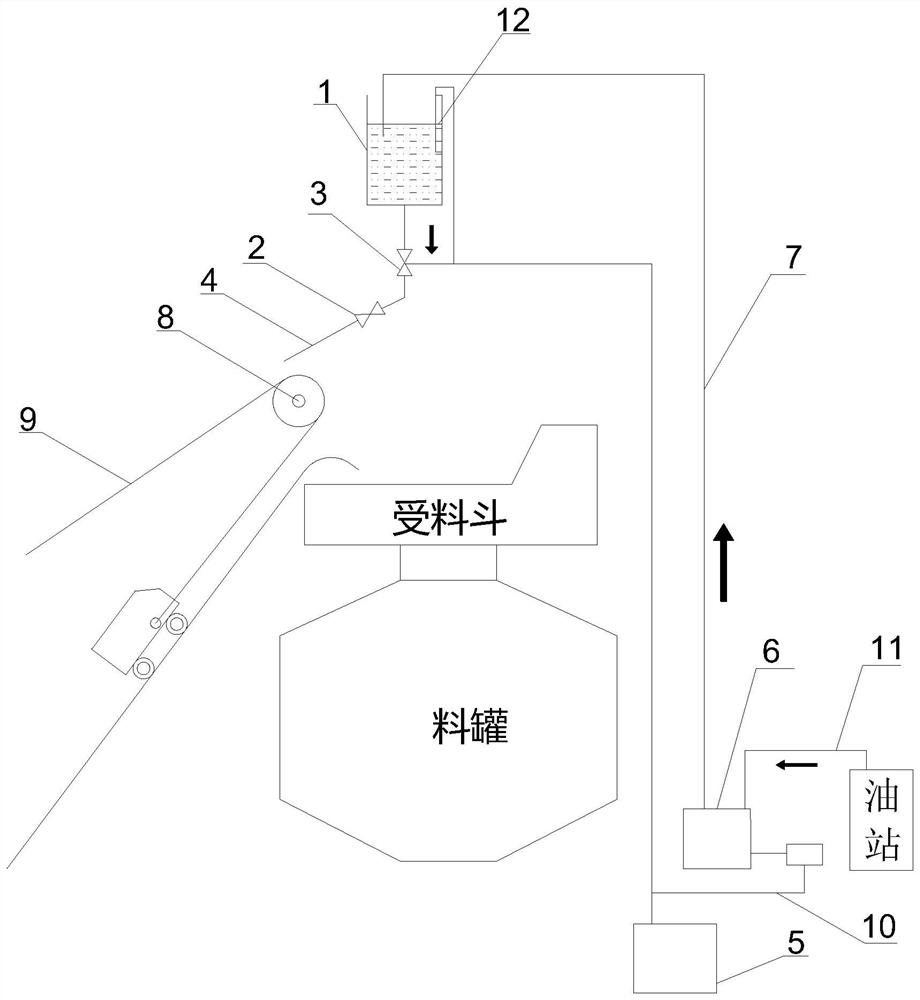

[0021] like figure 1 As shown, in order to solve the above-mentioned problems of high labor intensity, high risk of high-altitude operation, and low smearing efficiency brought about by manual smearing; this implementation provides a specific automatic lubrication device for the steel wire rope of the main hoist for blast furnace feeding, and the main hoist for the furnace top. The two fixed pulleys 8 share a lubricating oil storage tank 1, which is connected to the inclined bridge through a bracket, and the lubricating grease storage tank 1 is divided into two parts: an oil discharge device and an oil supply device; The oil discharge device consists of an oil discharge pipe 4, an electromagnetic oil discharge valve 3 and a flow regulating valve 2, and the connection method is: the bottom outlet of the lubricating oil storage barrel 1, the inlet of the electromagnetic oil discharge valve 3, the outlet of the electromagnetic oil discharge valve 3 and the flow rate The inlet of ...

Embodiment 2

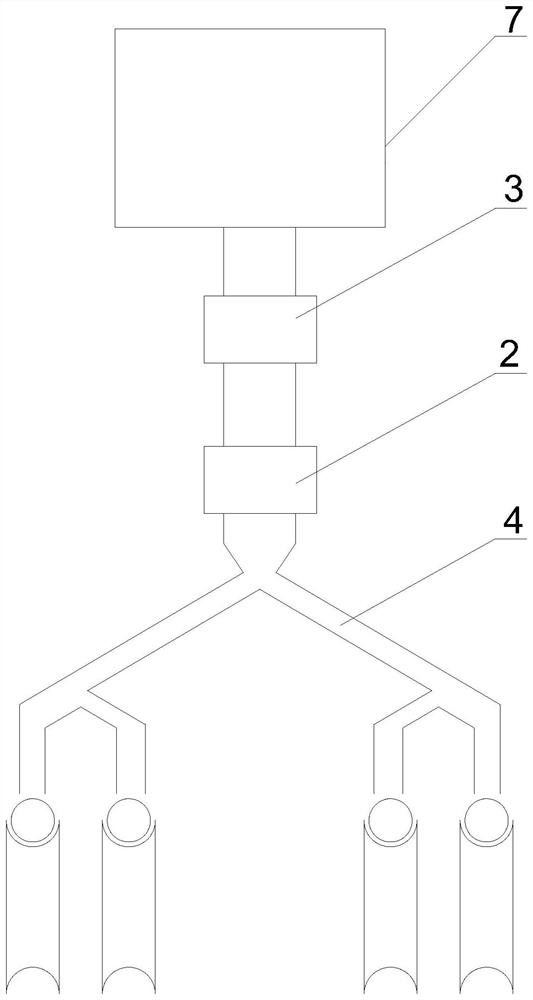

[0023] like figure 2 As shown, on the basis of Embodiment 1, at least one tee pipe is connected to the outlet of the oil discharge pipe 4 at the outlet of the flow regulating valve 2 to form at least two branch nozzles, and each branch outlet is below the outlet of the nozzle. Corresponding to a fixed pulley, multiple branch pipes are connected at the outlet to one or more pulleys and wire ropes at the same time with intermittent or continuous dropping points to meet the actual environment of workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com