Preparation method of thick-film hybrid circuit substrate side resistors

A technology of thick film mixing and substrate side, which is applied in the direction of resistance manufacturing, circuit, resistor, etc., to achieve the effect of wide resistance range, high precision and increased integration density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

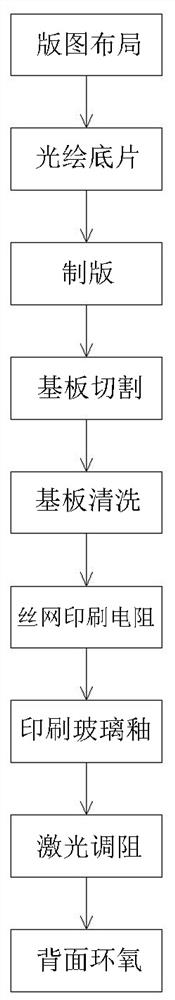

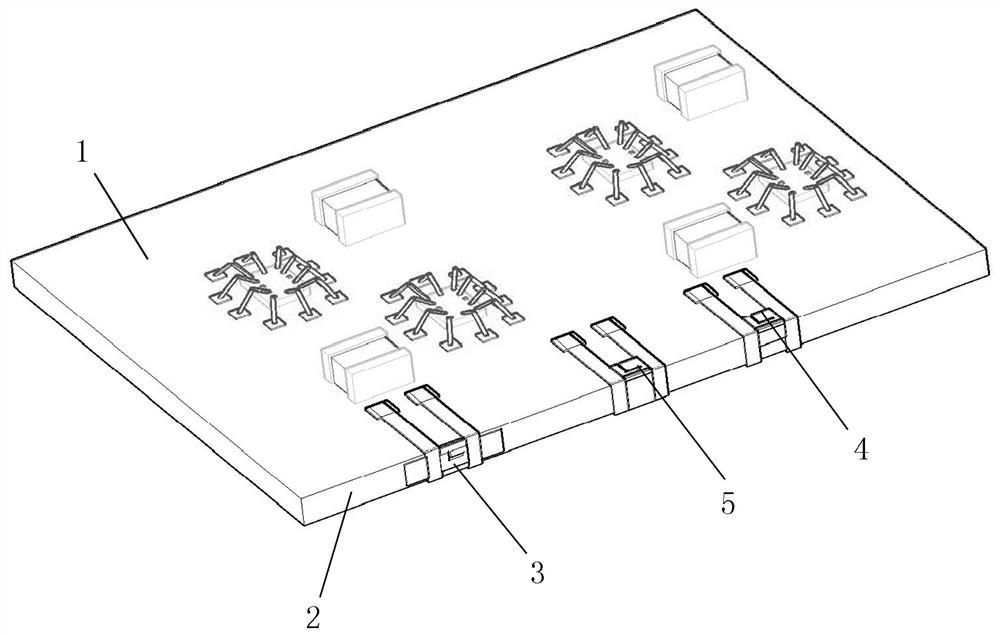

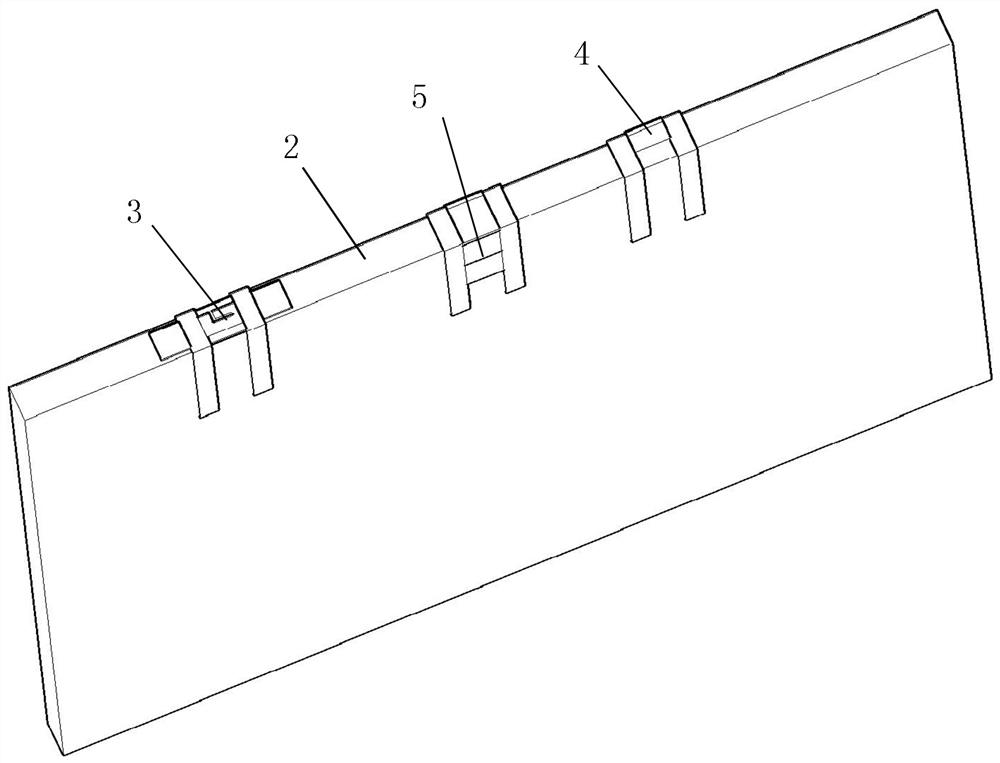

[0023] combine Figure 1~3 As shown, the present invention provides a method for preparing side resistors of a thick-film hybrid circuit substrate, comprising the following steps:

[0024] S1. Carry out the layout layout according to the circuit schematic diagram, determine the resistor positions distributed on the side 2 of the substrate 1, and obtain the resistor layout of the thick film hybrid circuit; there are three types of side resistors, the first type of side resistor 3 is only located on the side of the substrate, and the second type The side resistor 4 spans the side of the substrate and any surface above and below the substrate at the same time, that is, the resistor spans two surfaces; the third type of side resistor 5 spans the side of the substrate and the upper and lower surfaces of the substrate at the same time, that is, the resistor spans three surfaces;

[0025] S2. Light painting negatives, transfer the resistance layout of the thick film hybrid circuit in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com