Station distribution method and flexible intelligent processing production line

A distribution method and intelligent processing technology, applied in conveyor control devices, instruments, conveyors, etc., can solve the problems of difficulty in balancing the operation time of the front and rear workstations, and the inability to engage in the production of multiple products at the same time, and achieve flexible workstation settings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

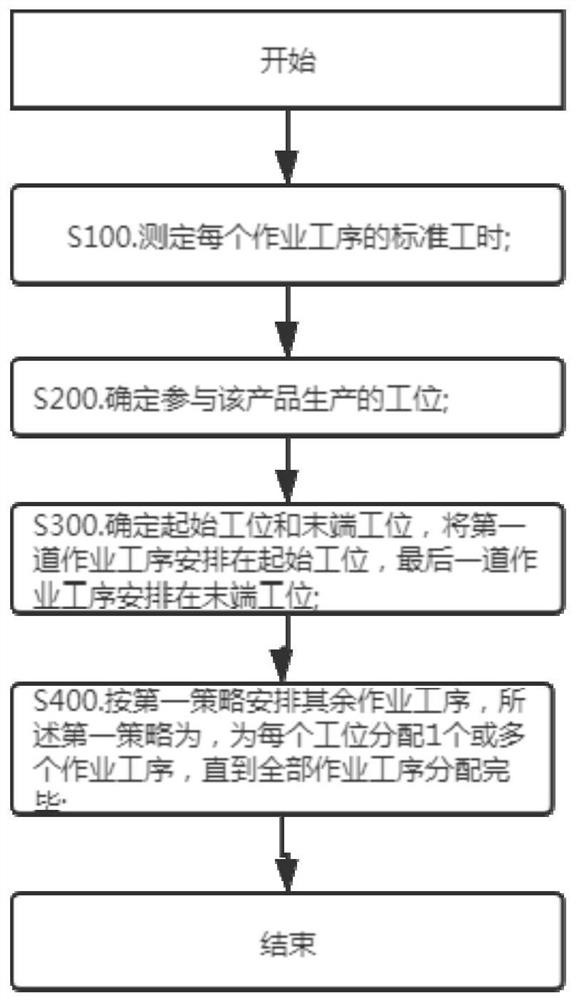

[0051] attached figure 1It is a flow chart of the station allocation method of an embodiment. On the processing production line including the circulation conveying line, there is a method for station allocation as follows:

[0052] S100. Determining the standard working hours of each operation procedure;

[0053] S200. Determine the workstations involved in the production of the product;

[0054] S300. Determine the start station and the end station, arrange the first operation procedure at the start station, and arrange the last operation procedure at the end station;

[0055] S400. Arrange the rest of the work procedures according to the first strategy. The first strategy is to assign one or more work procedures to each workstation until all the work procedures are allocated.

[0056] Take the following production line of a leather handbag A as an example. After the process of cutting (cutting the leather and lining to a suitable size and shape) and shoveling (shaving the ...

Embodiment 2

[0070] The station arrangement method of producing two or more products at the same time on a circular conveyor line is based on the implementation of 1. The step S200 of determining the stations participating in the production of the product also includes grouping the stations participating in the production according to the product, and each product production corresponds to a group of stations, and each group of stations is regarded as an independent production line for station arrangement.

[0071] Take the simultaneous production of handbag A and leather handbag B on one production line as an example:

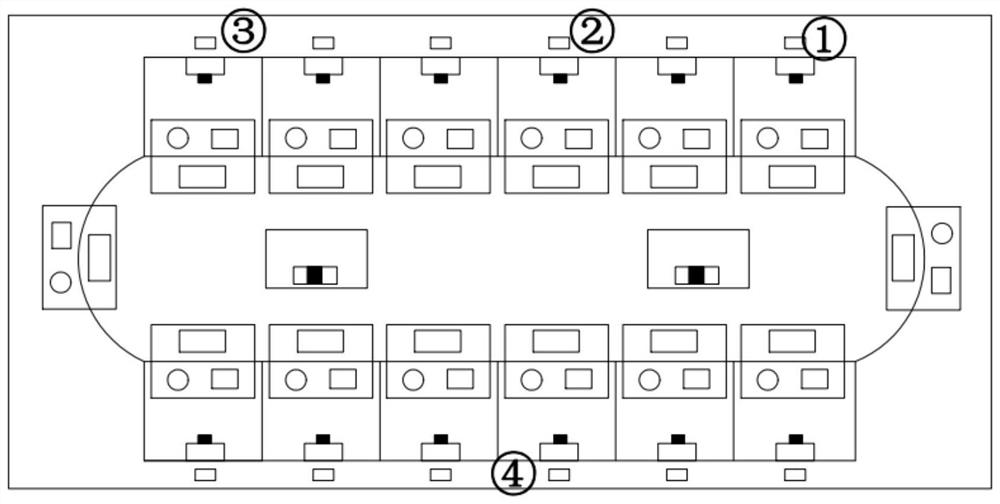

[0072] Table 3 A production line with a circular conveyor line, leather handbag A and leather handbag B are produced at the same time. Among them, leather handbag A has 8 working procedures and 4 stations; leather handbag B has 10 working procedures and 5 working stations Stations, station ① to station ④ leather handbag A production station group, station ⑤ to station 9 ar...

Embodiment 3

[0079] See attached Figure 5 , a flexible intelligent processing production line, including a processing station 10, a loading tray 20, and a circulating conveying line 30;

[0080] The loading tray 20 is used to load the product to be processed and the previous process identification 21, and the content of the previous process identification can be replaced or rewritten;

[0081] The circular conveying line 30 is used for circularly conveying the carrier tray 20;

[0082] The processing stations are arranged on one side of the circulating conveying line 30 .

[0083] During operation, the initial station is used for feeding materials, and the loading tray 20 with the product to be processed and the previous process identification 21 circulates 30 in the circular conveying line, and the worker obtains the information that the material arrives at the station according to the previous process identification 21, The product to be processed is taken out for processing. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com