Water-based paint based on solvent type polyurethane curing agent and preparation method of water-based paint

A polyurethane curing agent and water-based coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor water resistance, high cost, and poor thickness of the bursting film, and achieve good bursting film thickness and low cost price , good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

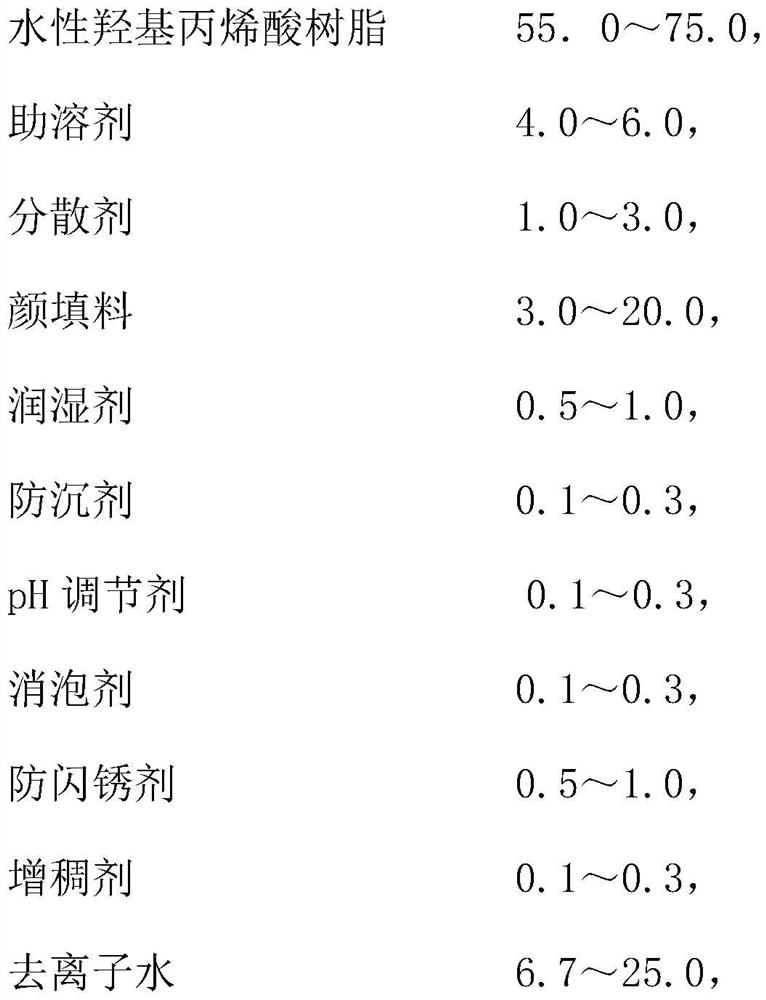

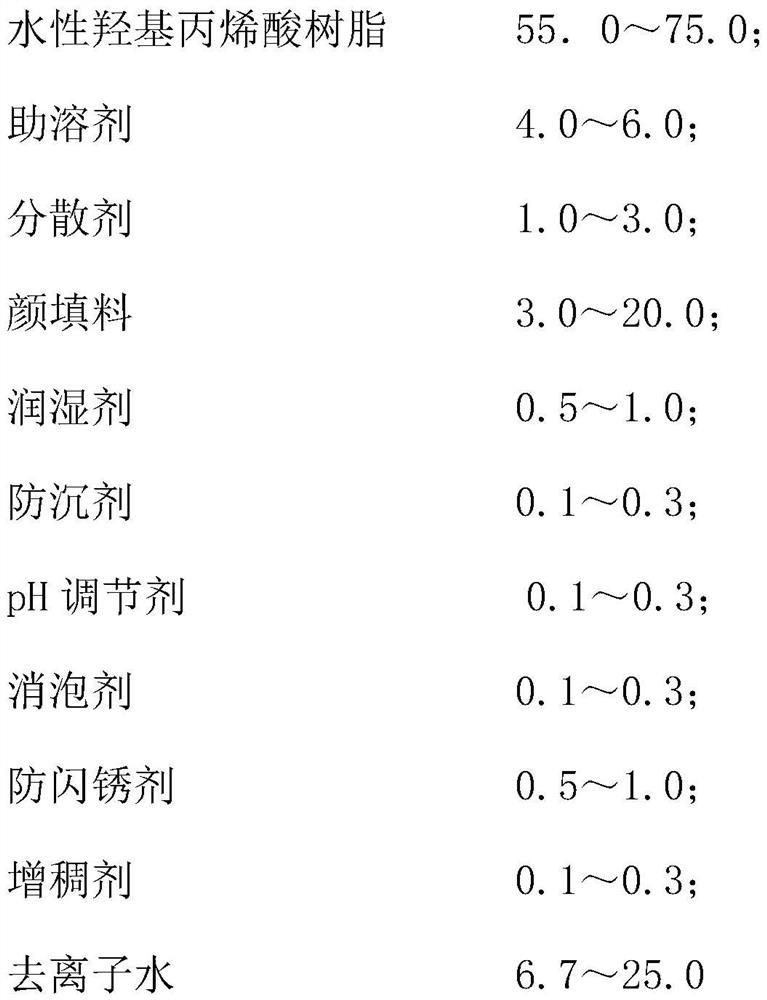

Method used

Image

Examples

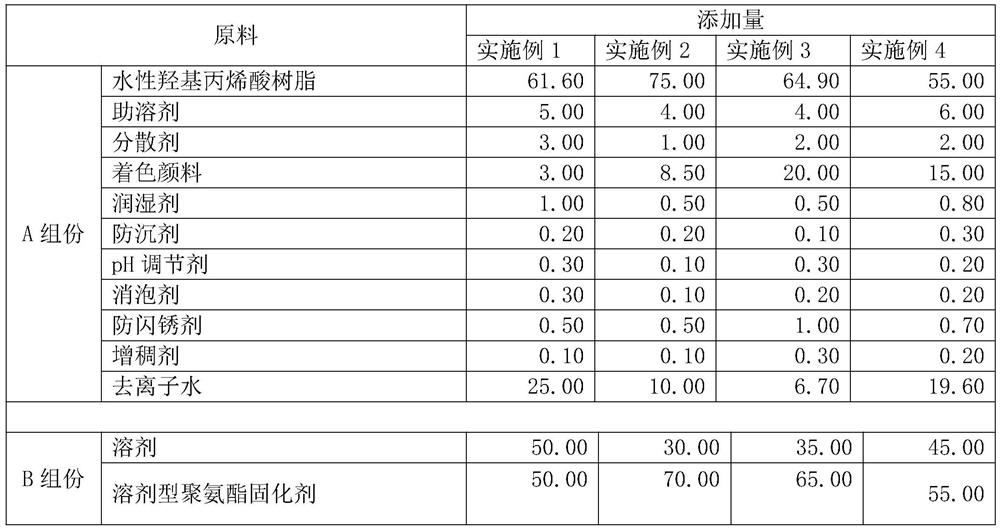

Embodiment 1

[0041] The preparation process is as follows:

[0042] ①Put 8.00 parts of deionized water in the first plastic tank, then add 0.20 parts of the anti-settling agent at a speed of 300 RPM, then gradually increase the speed to 3000 RPM, and keep stirring for 20 minutes to make an anti-settling slurry for later use;

[0043] ②Add the remaining 17.00 parts of deionized water to the second plastic tank, then add the 3.00 parts of the dispersant and the anti-settling slurry prepared in step ① at a speed of 1500RPM; then add 3.0 parts of coloring pigments at 500RPM, Stir for 10 minutes; add 0.30 part of defoamer at 1500RPM and stir at 2000RPM for 20 minutes;

[0044] ③Put the product prepared in step ① and step ② into the dispersion cylinder and grind for an hour at 2500RPM until the fineness is less than 10μm, then filter the colored slurry for later use;

[0045] ④Put 61.60 parts of self-made water-based acrylic resin 1 into the third plastic tank, and then add 5.00 parts of cosolv...

Embodiment 2

[0051] The preparation process is as follows

Embodiment 2

[0053] ①Put 8.00 parts of deionized water in the first plastic tank, then add 0.20 parts of the anti-settling agent at a speed of 300 RPM, then gradually increase the speed to 3000 RPM, and keep stirring for 20 minutes to make an anti-settling slurry for later use;

[0054] ②Add the remaining 2.00 parts of deionized water to the second plastic tank, then add the 1.00 parts of the dispersant and the anti-settling slurry prepared in step ① at a speed of 1500RPM; then add 8.50 parts of coloring pigments at 500RPM, Stir for 10 minutes; add 0.10 parts of defoamer at 1500RPM and stir at 2000RPM for 20 minutes;

[0055] ③Put the product prepared in step ① and step ② into the dispersion cylinder and grind for an hour at 2500RPM until the fineness is less than 10μm, then filter the colored slurry for later use;

[0056] ④Put 75.00 parts of self-made water-based acrylic resin 2 into the third plastic tank, and then add 4.00 parts of cosolvent, 0.50 parts of wetting agent and the color p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap