Sliding type silo cantilever tripod structure and mounting method

A tripod and sliding technology, applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc., can solve the problems of inconvenient and convenient dismantling, high positioning requirements, size deviation, etc., and achieve convenient and fast installation and dismantling. , beautiful appearance, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

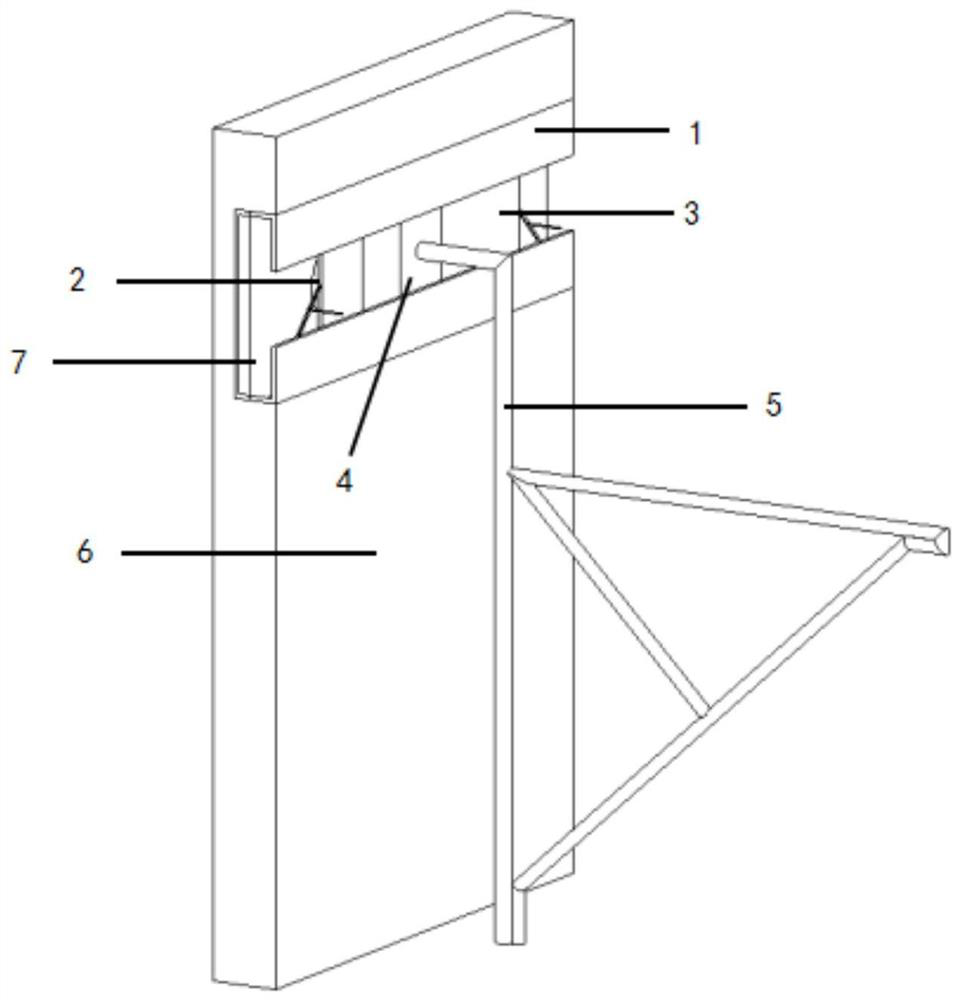

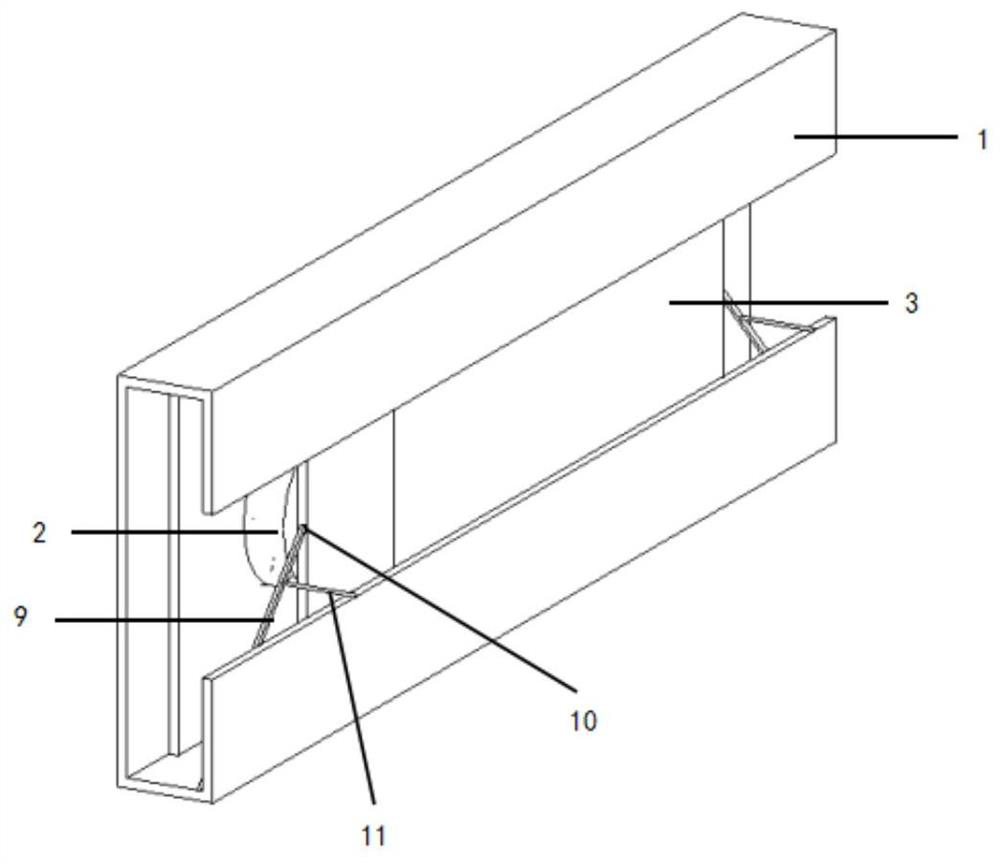

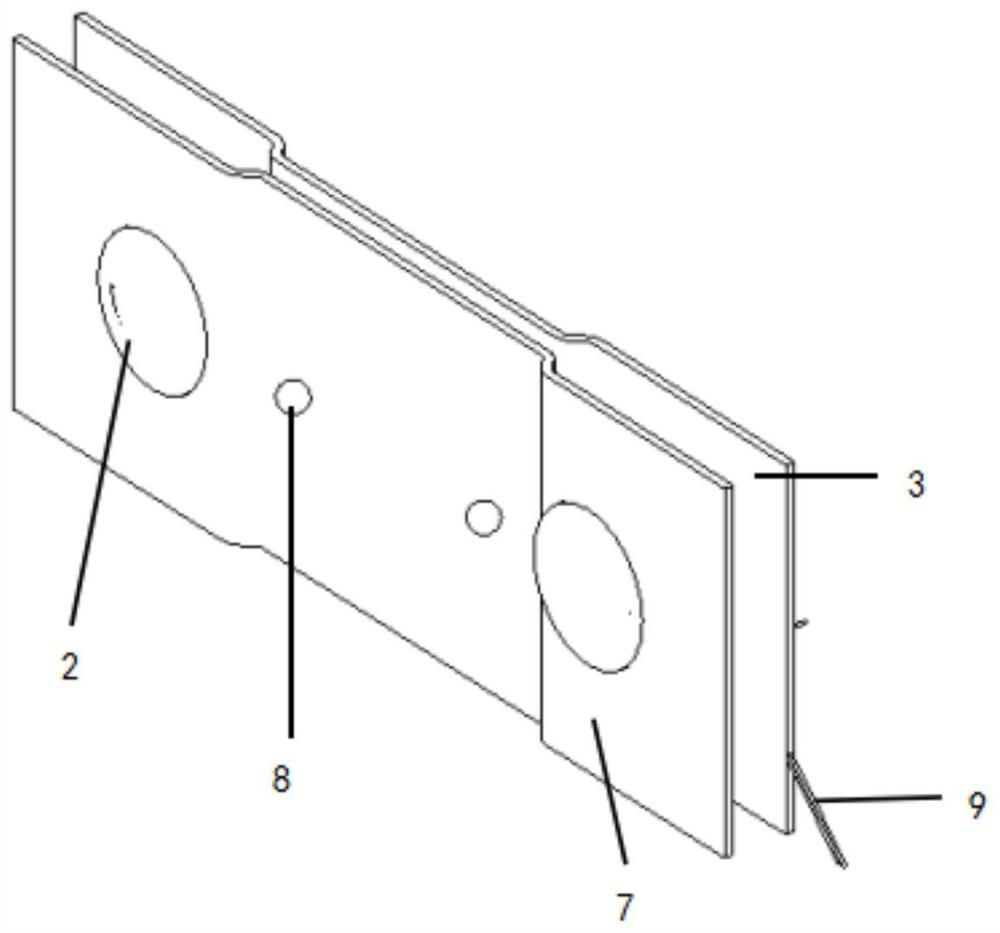

[0034] The sliding type silo cantilevered tripod structure designed by the present invention includes a C-shaped card slot 1, a sliding connection mechanism and a braking device for restricting the movement of the sliding mechanism. The fixed end of the overhanging tripod 5 is provided with a hanging plate 4, The tripod hanger 5 is integrated with the hanging plate 4, and the connection is firm; the C-type card slot 1 is pre-buried in the silo wall 6; the sliding connection mechanism includes an elastic baffle 3, a spring 2, and a sliding baffle 7, and the spring 2 is arranged on the Between the elastic baffle 3 and the sliding baffle 7 arranged oppositely, the elastic baffle 3 is provided with an indented groove matched with the hanging plate 4; the contact surface between the sliding baffle 3 and the C-shaped slot is provided with a ball 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com