Double-winding free piston linear generator and control method

A technology of linear generators and linear motors, applied in the direction of controlling mechanical energy, engine components, machines/engines, etc., can solve the problems of FPLG advantages that cannot be brought into play, long response time, shutdown conditions, etc., to solve the problem of excessive response time of motor mode conversion Long, solve the insufficient power of the piston, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment takes the current rear-mounted FPLG as an example for illustration. Of course, this does not constitute a limitation on the protection scope of this patent, and this patented technology is also applicable to other types of FPLG.

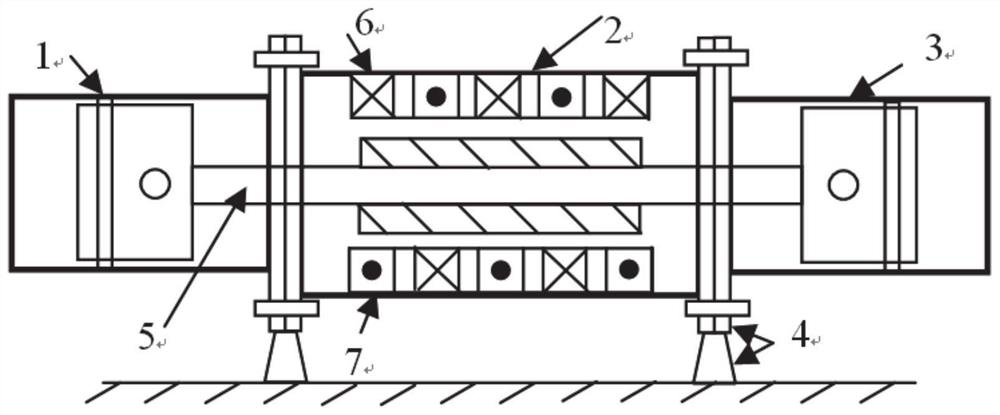

[0035] The back-mounted FPLG is equipped with an engine at both ends of the generator core shaft. Generally, a two-stroke engine is used symmetrically, and a linear motor is arranged in the middle. The motor has two functions of a motor and a generator, which can realize the conversion of different working modes.

[0036] Due to the change of the combustion cycle of the engine, the mutual conversion between the electric mode of the linear motor and the power generation mode, and the response time after the conversion, it is very difficult for the current FPLG to operate stably.

[0037] Based on this, according to an embodiment of the present invention, an embodiment of a double-winding free-piston linear generator is proposed, ...

Embodiment 2

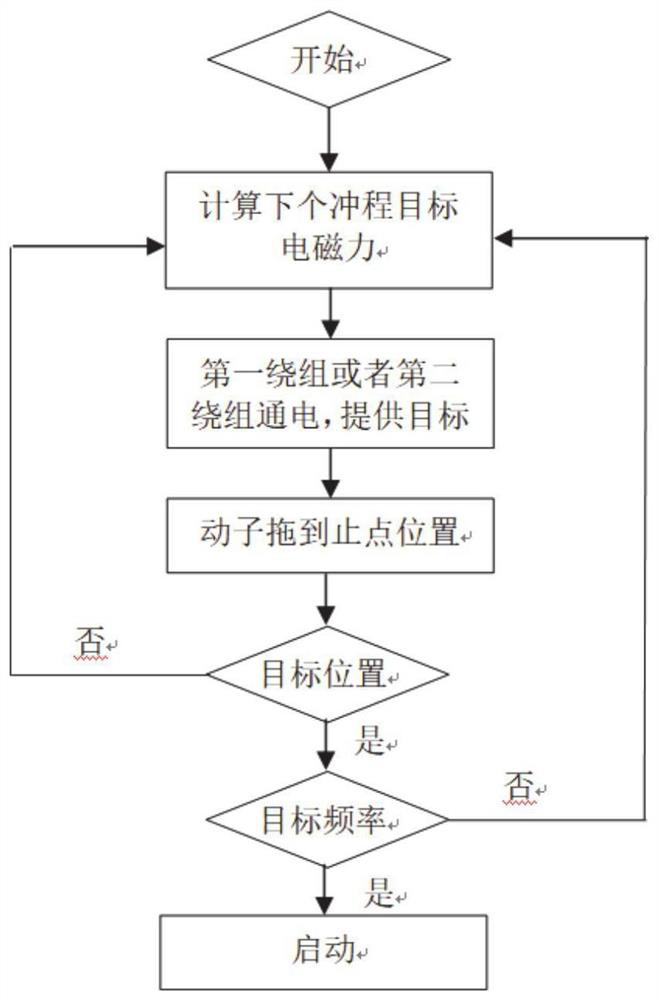

[0074] According to an embodiment of the present invention, an embodiment of a control method of a double-winding free-piston linear generator is provided, including: a start-up process and a normal operation process;

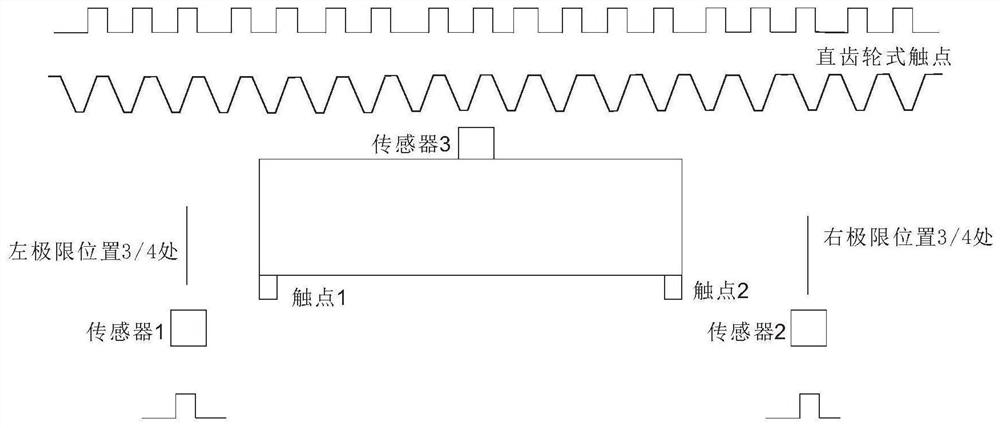

[0075] During the start-up process, the first winding is energized and the mover is driven to move to the left. During this process, the mover is affected by the drag force and the pressure of the compressed gas of the left cylinder, and the mover experiences a process of acceleration first and then deceleration to zero. When the drag force is small, the mover cannot reach the designated top dead center position during the first dragging process, and the frequency of the mover is also low at this time. Through the sensing element and the gear contact device, the mover can be detected. The real-time position of the mover, when the speed of the mover reaches zero, it indicates that the first dragging process is over, the first winding is powered off, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com