Coaxial heat exchanger, evaporator, condenser and refrigerating system

A refrigeration system and heat exchanger technology, applied in the fields of condensers, refrigeration systems, evaporators, and coaxial heat exchangers, can solve the problems of low refrigerant density, low heat transfer coefficient, large pressure drop, etc. The effect of large thermal coefficient, low heat transfer coefficient and small heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

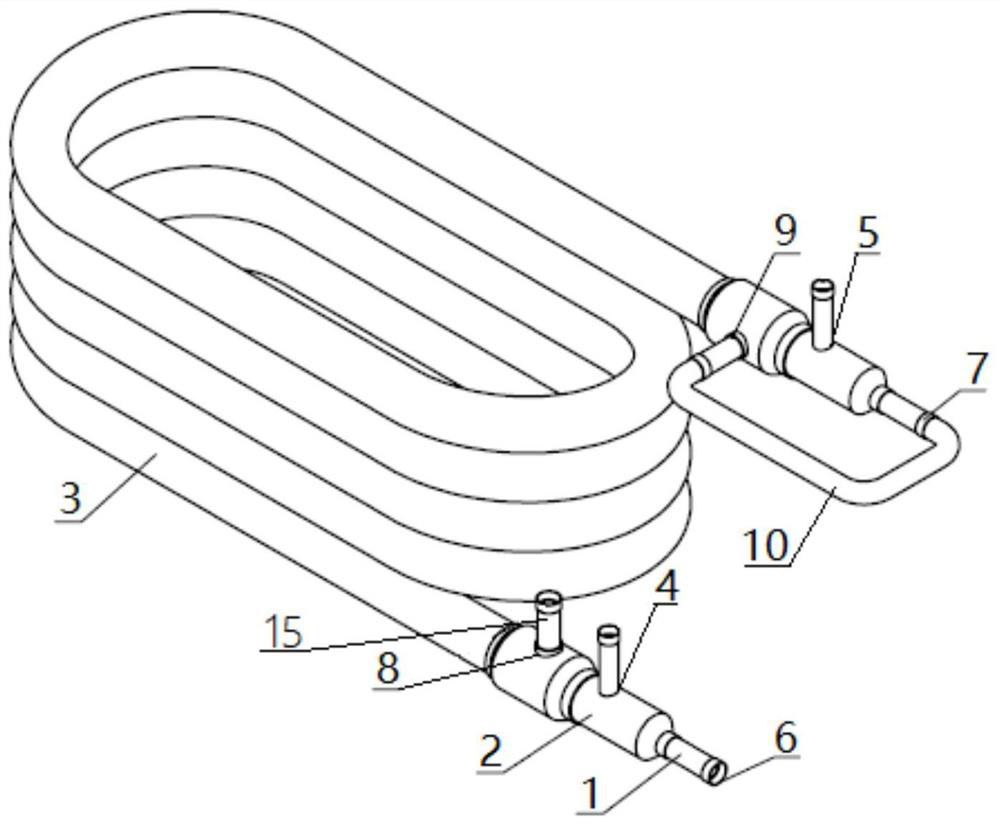

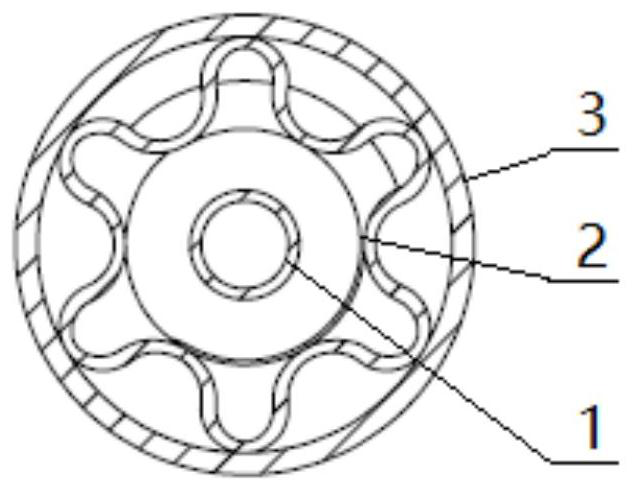

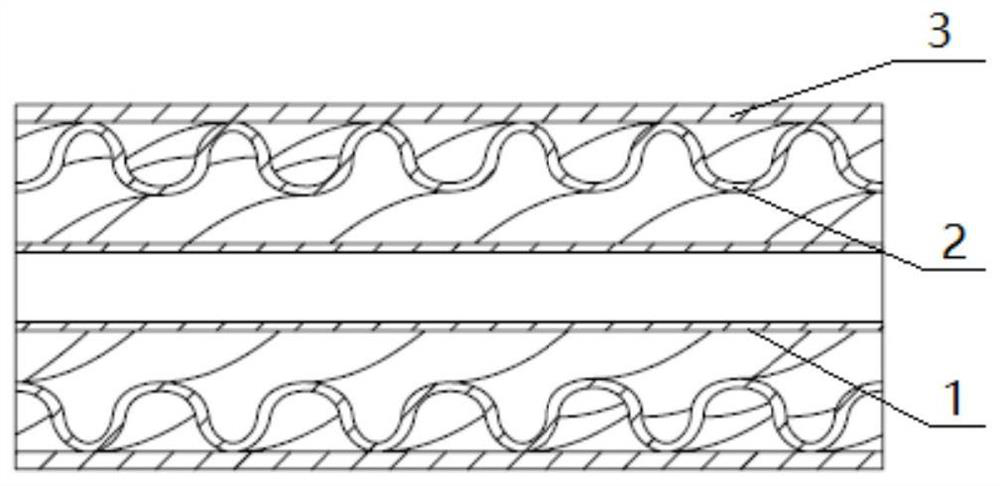

[0036] This embodiment provides a coaxial heat exchanger, including at least one connecting pipeline 10, at least one brine pipeline 2 and multiple refrigerant pipelines, and the brine pipeline 2 and the refrigerant pipeline are arranged coaxially , the inner side and the outer side of the brine pipeline 2 are respectively provided with refrigerant pipelines, and the refrigerant pipelines are connected by connecting pipelines 10 . Wherein the connecting pipeline 10, the brine pipeline 2 and the refrigerant pipeline can be copper pipelines or stainless steel pipelines or nickel-white copper pipelines or steel pipelines or titanium pipelines or pipelines of other materials; The overall pipeline of the heater can be as follows figure 1 The shown U-shaped structure or square structure or circular mosquito-repellent-repellent incense structure or double-circle structure or other shaped structures are arranged.

[0037] Such as figure 1As shown, in this embodiment, there are two r...

Embodiment 2

[0043] This embodiment provides an evaporator for evaporating and heat-exchanging refrigerant in a refrigeration system, including the coaxial heat exchanger in Embodiment 1, and using the coaxial heat exchanger for refrigerant and brine heat exchange.

Embodiment 3

[0045] This embodiment provides a condenser for condensing and heat-exchanging refrigerant in a refrigeration system, including the coaxial heat exchanger in Embodiment 1, and using the coaxial heat exchanger for refrigerant and brine heat exchange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com