PWM dimming type LED light-emitting system capable of avoiding inductive current overshoot

A technology of inductive current and lighting system, applied in the field of LED dimming, can solve problems such as insufficient current resistance, insufficient response speed of the switching system, loss of adjustment function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

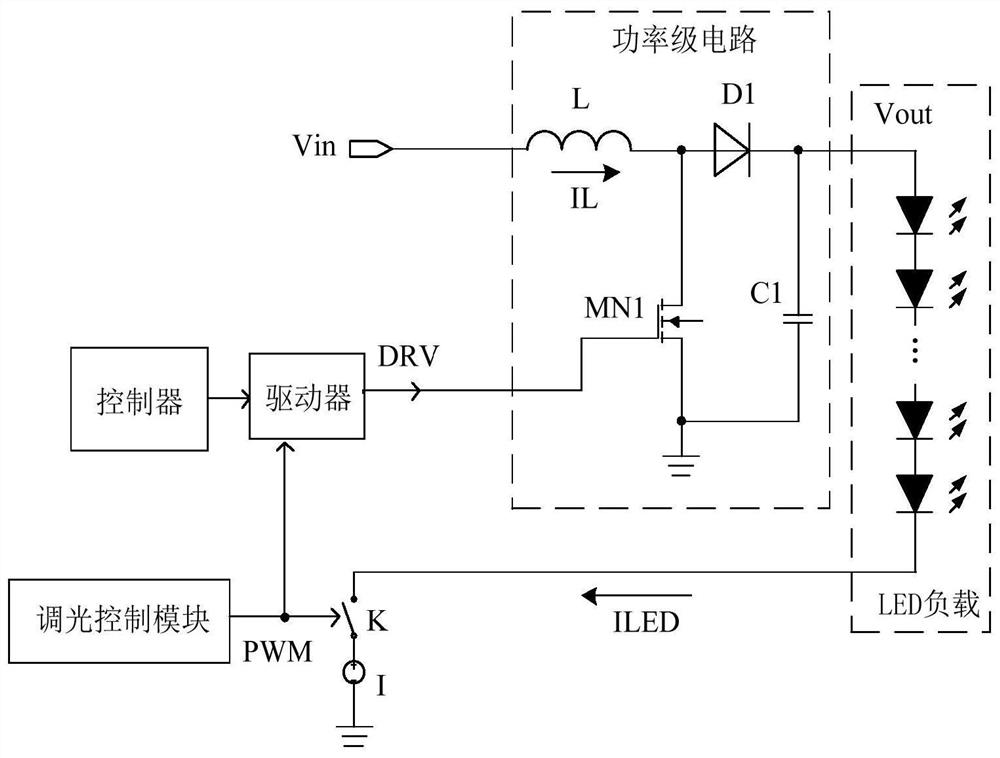

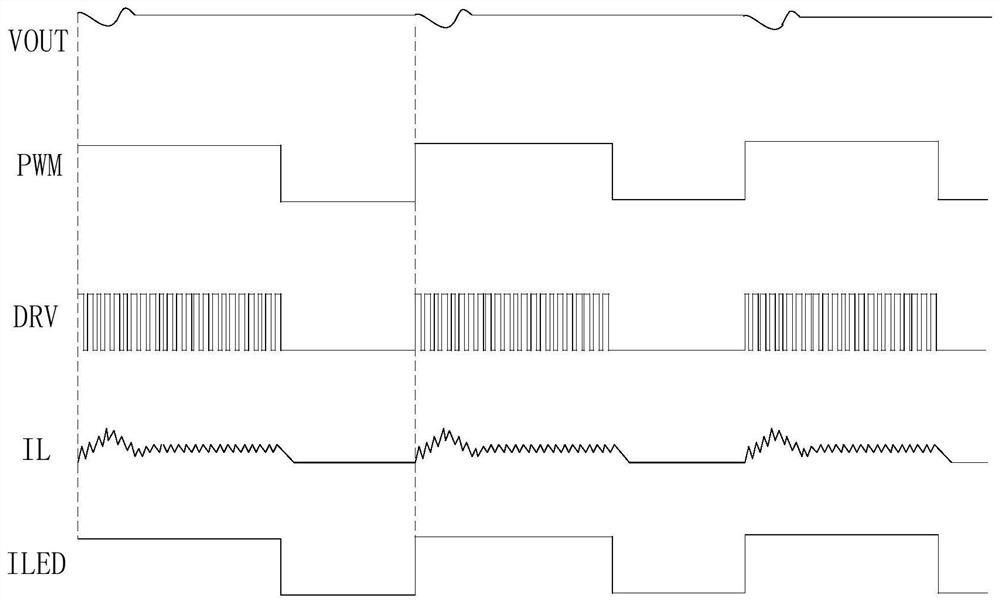

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

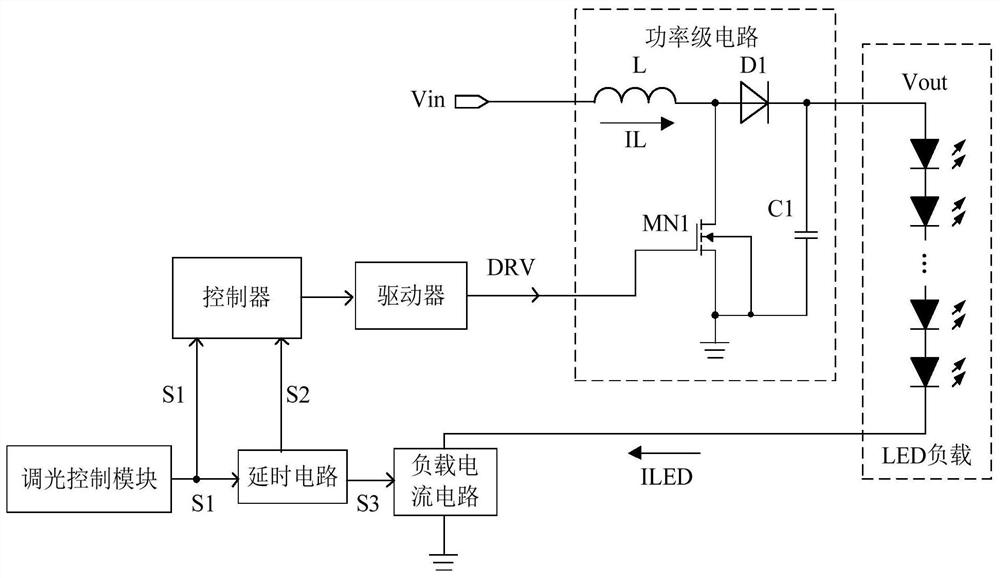

[0026] This application discloses a PWM dimming LED lighting system that avoids inductor current overshoot, please refer to image 3 The system architecture diagram shown also includes the power stage circuit and LED load. The power stage circuit mainly includes inductor L, switch tube MN1, capacitor C1 and diode D1. The circuit structure of the power stage circuit and LED load is similar to the conventional one. This application No longer. The system also includes a dimming control module, a delay circuit, a load current circuit, a driver and a controller, and the power stage circuit, the LED load and the load current circuit form a series circuit.

[0027] The dimming control module is connected to the controller and the delay circuit and outputs PWM signal S1. The output terminals of the delay circuit are respectively connected to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com