System for storing compressed fluid

A storage system, a technology for compressing fluids, used in fluid handling, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

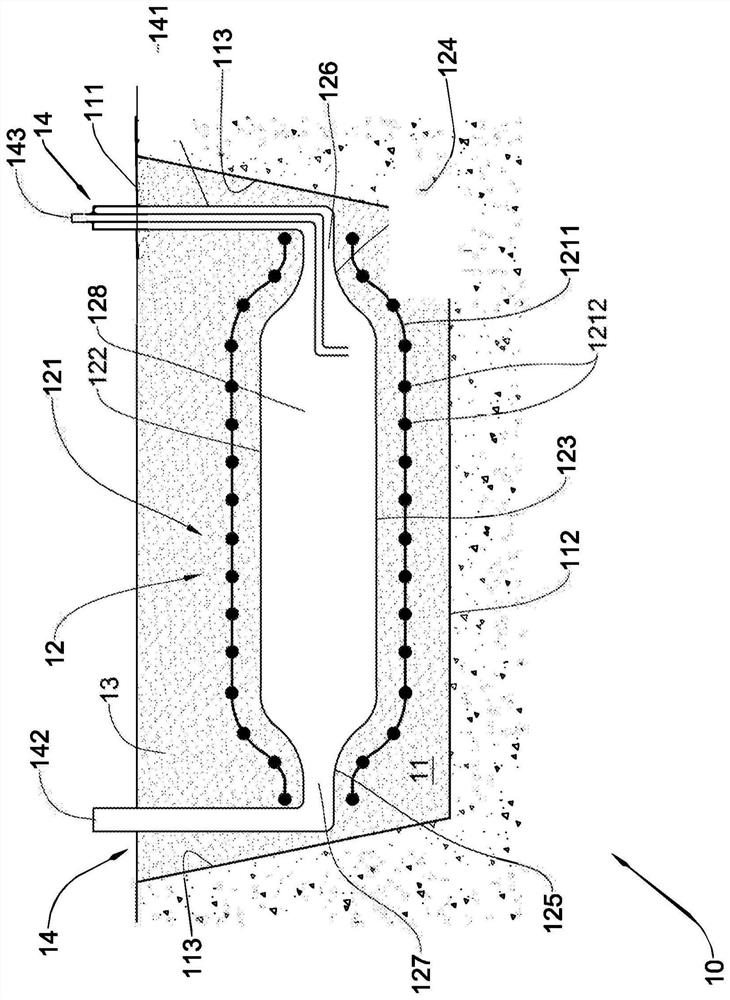

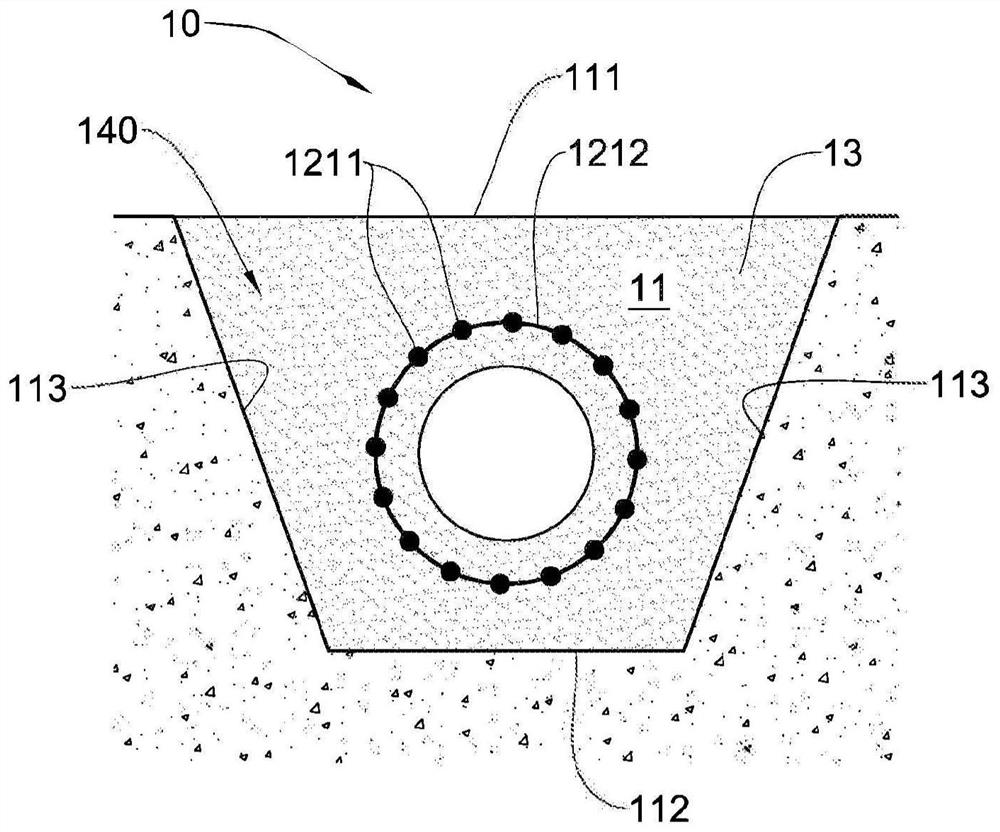

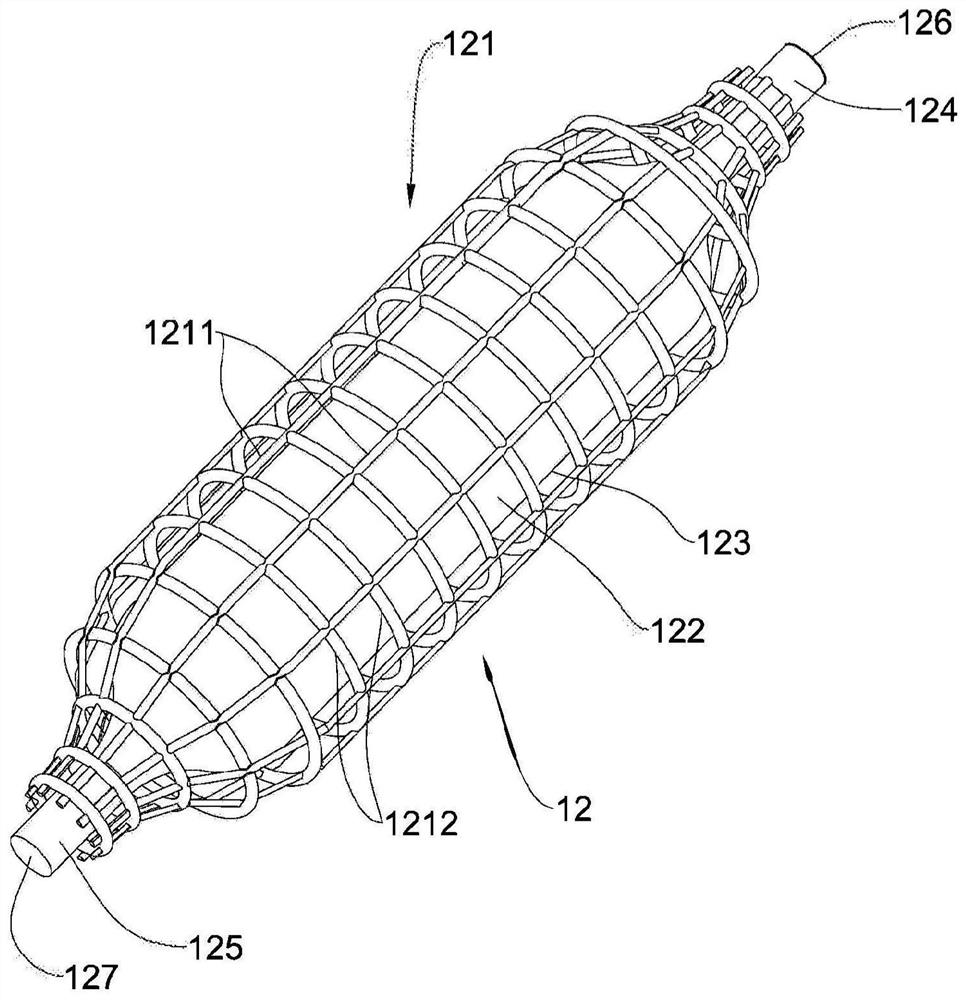

[0034] The principles and operation of an underground compressed gas storage system according to the present invention may be better understood with reference to the drawings and accompanying descriptions. It should be understood that these drawings are given for purposes of illustration only and are not meant to be limiting. It should be noted that for the sake of clarity, the figures illustrating various examples of the system of the present invention are not drawn to scale and are not to scale. Throughout the description of the present invention, the same reference numerals and alphabetic characters are used to identify those components that are common to the hydropneumatic energy storage systems and components thereof shown in the drawings. Provides a constructed example for the selected element. Those skilled in the art will appreciate that many of the examples provided have suitable alternatives that may be utilized.

[0035] refer to Figure 1A and Figure 1B , respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com