Precise wave-soldering flux spraying system

A spraying system and flux technology, applied in the direction of spraying devices, liquid spraying devices, auxiliary devices, etc., can solve the problems of inconvenient installation, poor structural installation, and affecting spraying operations, so as to improve spraying control accuracy, facilitate operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

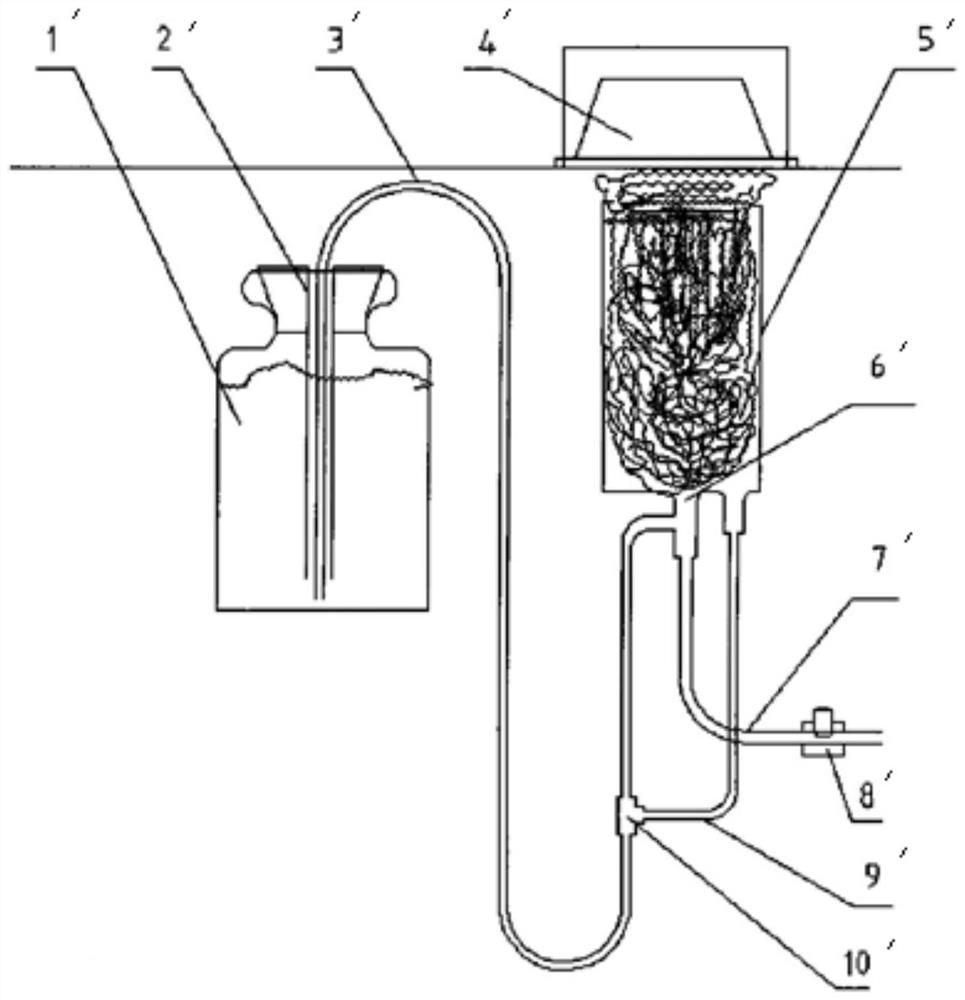

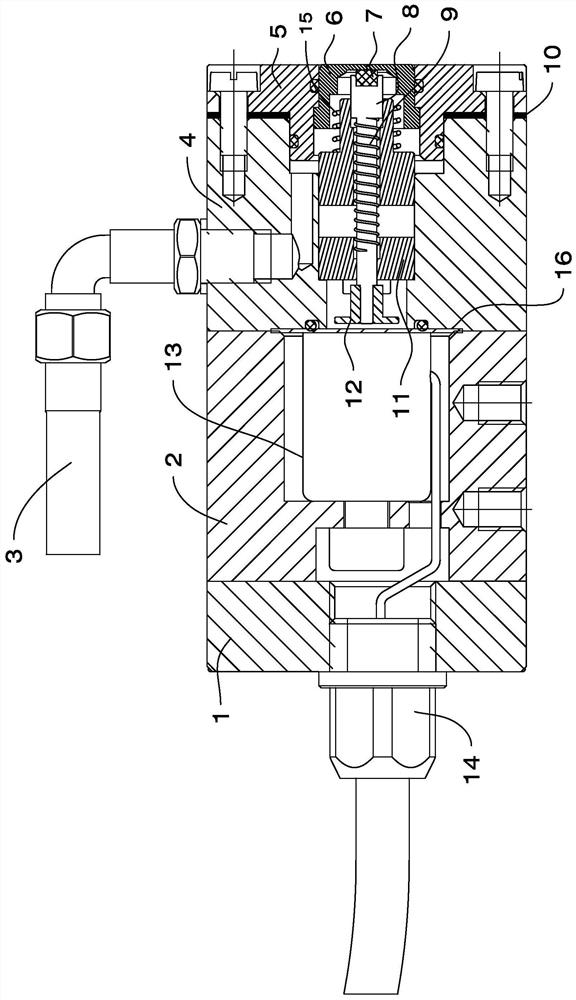

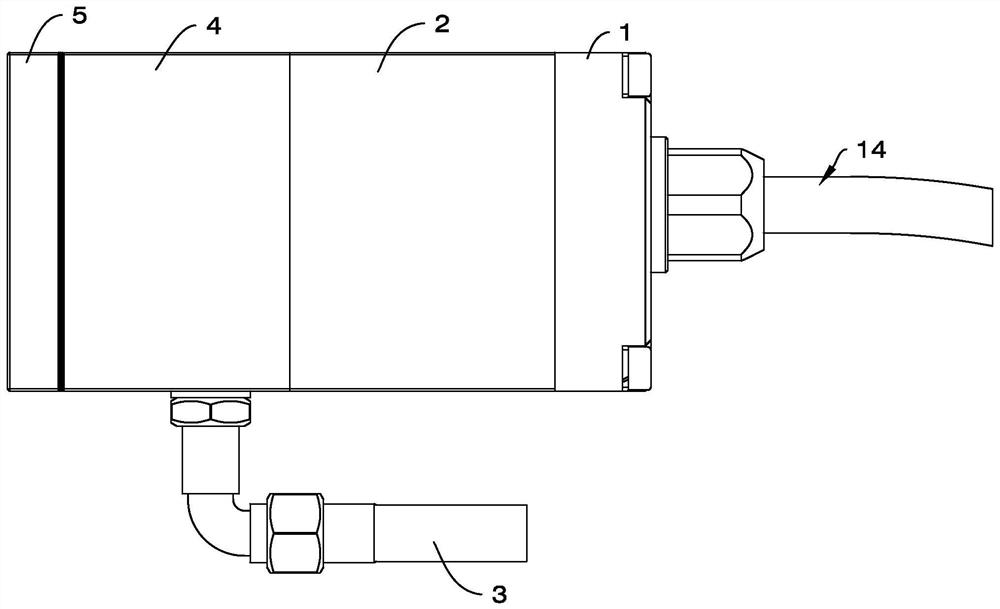

[0025] Such as Figure 2 to Figure 4 As shown, the wave soldering flux precision injection system of the present invention includes an upper gland 1 , a magnetic core seat 2 , a liquid storage chamber 4 and a nozzle seat 5 which are sequentially connected together from right to left. The upper gland 1 is provided with an electrical connector 14 for external power supply equipment. The electromagnet 13 in the magnetic core holder 2 is connected with an electrical connector 14 . The liquid storage chamber 4 is externally connected to the liquid inlet pipe 3, which reduces redundant pipe connections and sealing rings, and increases reliability. The liquid inlet pipe 3 is externally connected with flux supply equipment and compressed air supply equipment, which is convenient for inputting flux and compressed air, and the flux is sprayed out through the compressed air, and the working air source is convenient to obtain. At the same time, the liquid inlet pipe 3 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com