Casting paint spraying device

A technology for castings and painting racks, applied in the field of casting processing, can solve the problems of incomplete painting, uneven painting, and low painting efficiency, and achieve the effects of comprehensive and thorough painting, increasing the surrounding area, and speeding up the painting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

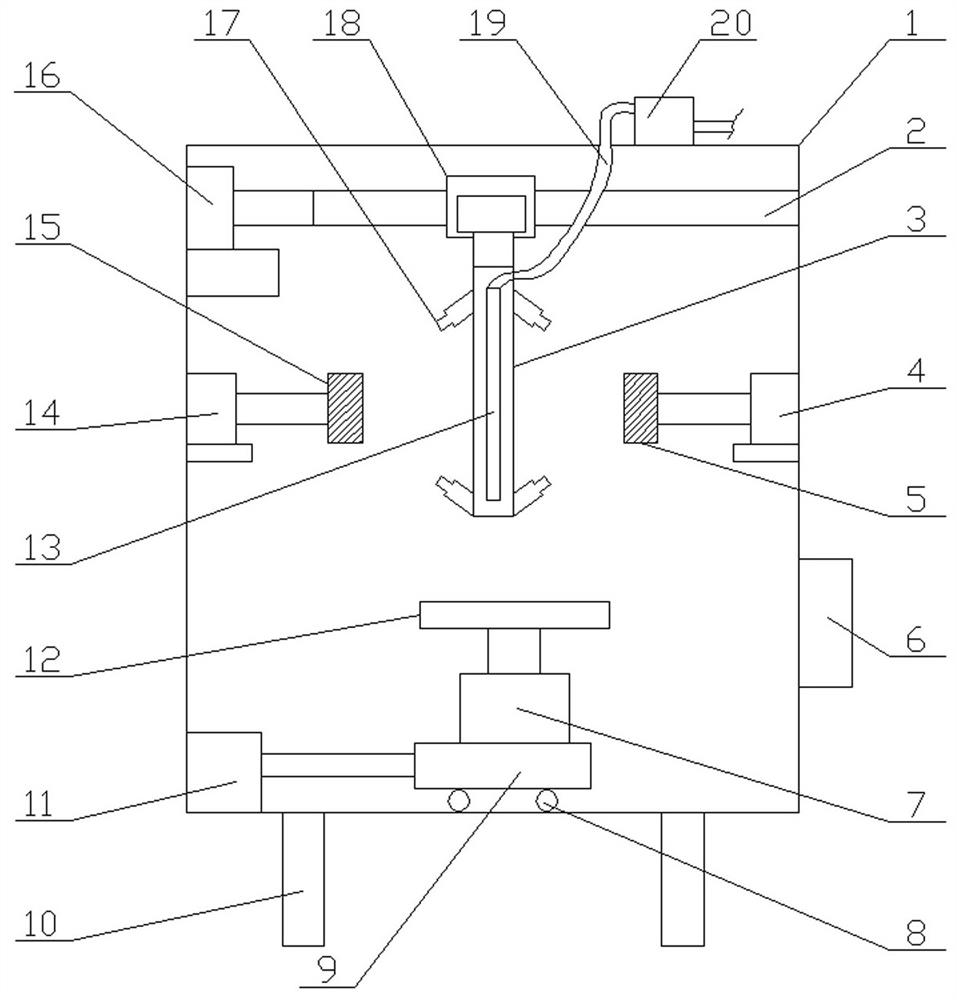

[0027] see figure 1 , the present invention provides a casting painting device, comprising a housing 1, a control unit 6 and a lateral movement device A, a lateral movement device B, a ring paint spraying frame 3 and a fixing device located in the housing 1, and the control unit 6 is PLC controller, a plurality of legs 10 are arranged at the bottom corner of the housing 1 .

[0028] The horizontal moving device A is arranged on the top of the housing 1, and the horizontal moving device A is provided with a cylinder 18. The piston rod of the cylinder 18 is fixedly connected with the circular ring paint spraying frame 3 vertically downward, and the circular ring paint spraying frame 3 is fixed along the Radially and vertically set and the inside is provided with shunt pipe 13, and described circular ring paint spray frame 3 both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com