Schottky barrier diode rectifying device and manufacture method thereof

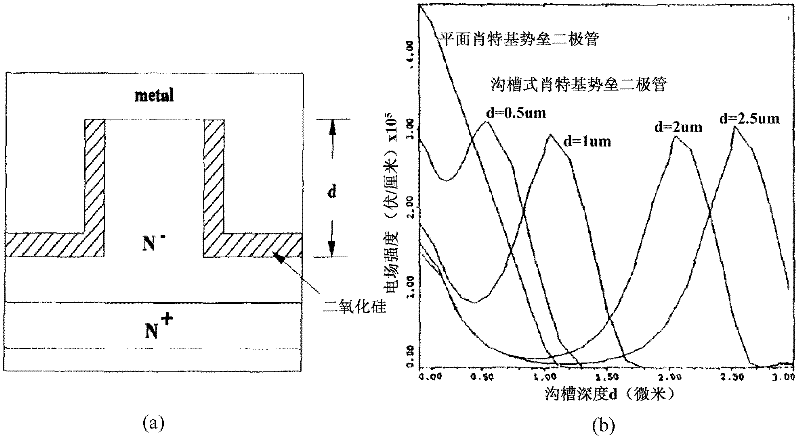

A diode rectification and Schottky potential technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem that the gap filling ability of the upper metal layer material is not good, and the surrounding area of the electric field intensity curve does not change significantly. Device reliability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

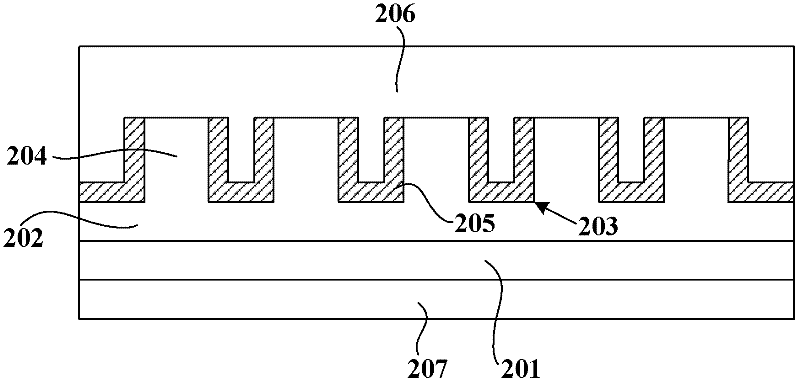

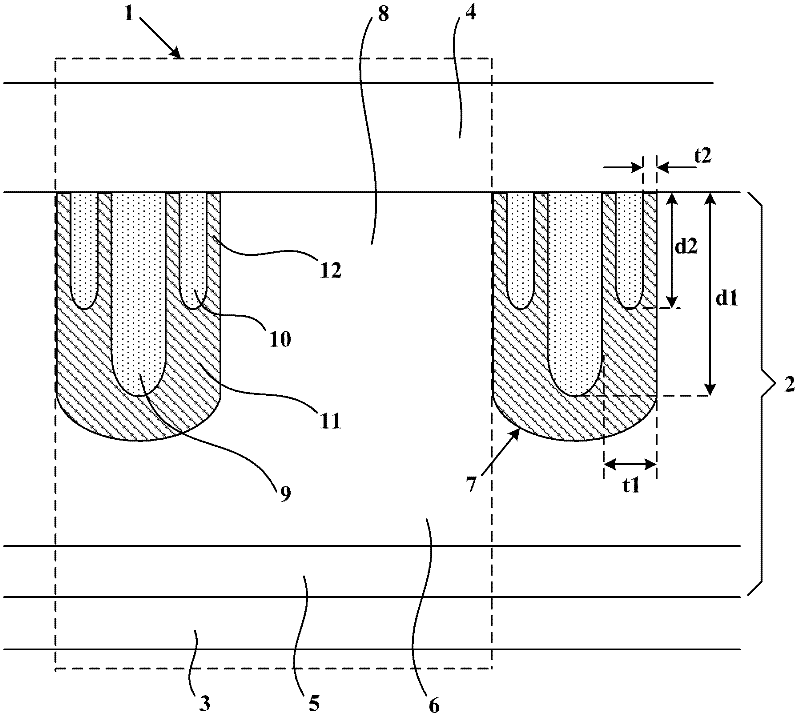

[0040] A Schottky barrier diode rectifier device, such as image 3 As shown, the active region of the device is composed of several Schottky barrier diode cells 1 connected in parallel; in cross-section, each cell 1 includes a silicon wafer 2, a lower metal layer 3 located on the back of the silicon wafer 2, The upper metal layer 4 located on the front side of the silicon wafer 2, the heavily doped single crystal silicon substrate 5 of the first conductivity type connected to the lower part of the silicon wafer 2 and the lower metal layer 3, the upper part of the silicon wafer 2 and the lower metal layer 3 The lightly doped monocrystalline silicon epitaxial layer 6 of the first conductivity type connected to the upper metal layer 4 is located on the upper part of the epitaxial layer 6 and opens to the trench 7 on the upper surface of the epitaxial layer 6, adjacent to the trench 7 The boss 8 formed in the region of the epitaxial layer 6 between, the heavily doped first conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com