Steam absorption system used during water adding, humidifying and dust falling of coke intermediate bin

An absorption system and intermediate storage technology, applied in the field of dry quenching, can solve problems such as pipeline blockage, affecting the normal operation of water, humidification and dust reduction systems, and achieve the effect of avoiding omissions, ensuring efficient and normal operation, and reducing corrosion and wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

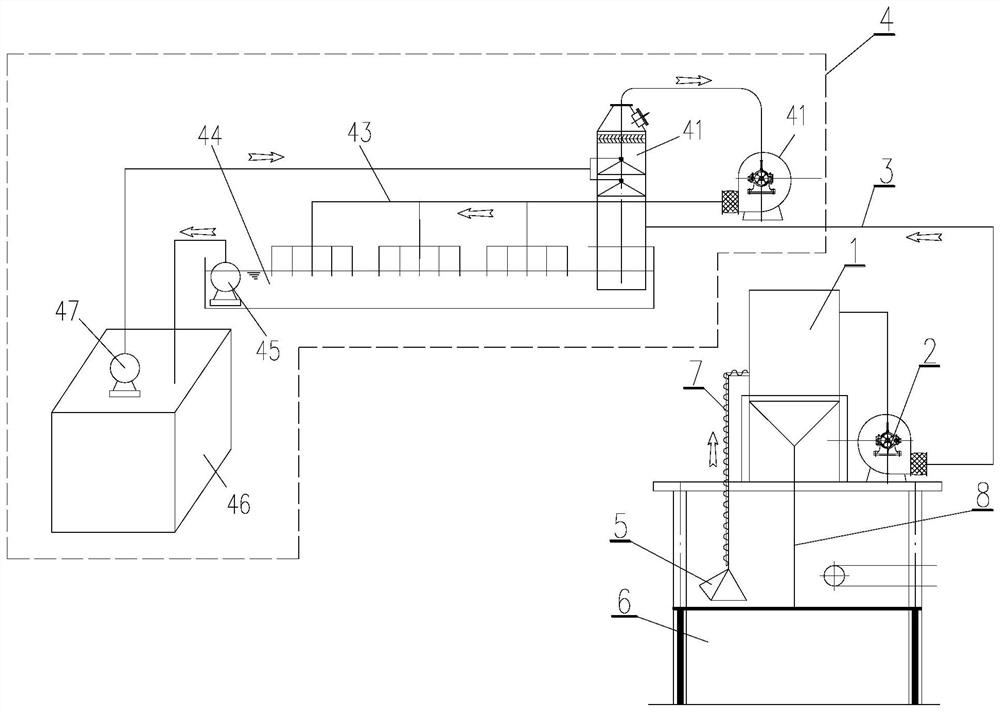

[0025] like figure 1 As shown in the present invention, a steam absorption system for adding water, humidifying and reducing dust to the coke tundish includes a suction hood 5 arranged on the upper part of the coke tundish 6, and a steam pipe 3 connected to the suction hood 5. Absorption device 4; also includes dust removal pretreatment device 1 and induced draft fan 2; said dust removal pretreatment device 1 is located on steam pipeline 3, and dust removal pretreatment device 1 is provided with steam inlet and is connected with suction hood 5, and dust removal pretreatment device 1 The steam outlet is connected to the steam absorption device 4, the water and dust outlet of the dust removal pretreatment device 1 is connected to the coke intermediate bin 6; the steam pipe 3 connecting the dust removal pretreatment device 1 and the steam absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com