Tool for solving problem that movable material of steel casting die is difficult to strip

A technology for steel castings and moulds, which is applied in the field of tools for solving the problems of steel casting mold live materials that are difficult to mold, and can solve the problems of reducing the yield of steel castings, low practicability, and mold deformation, so as to improve practicability and Effects of adaptability, increased flexibility and adaptability, increased stability and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

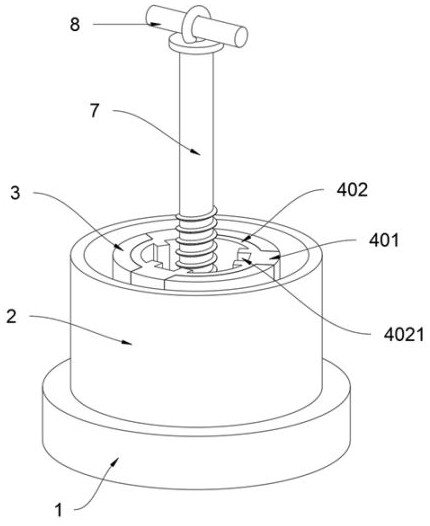

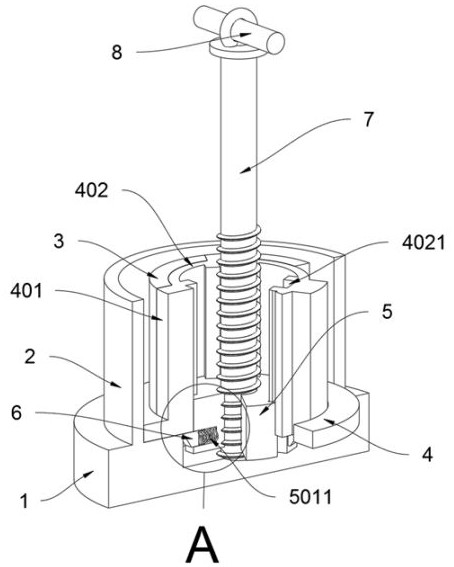

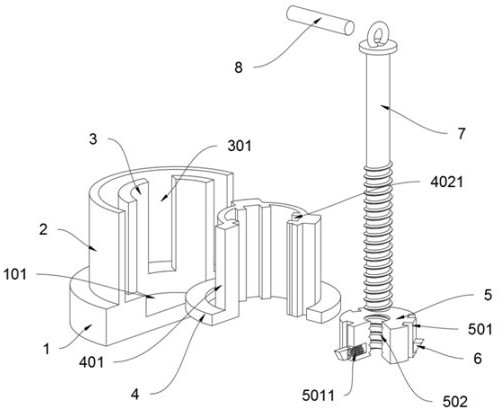

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036]The present invention provides a tool for solving the difficulty in mold removal of steel casting mold live materials, including a mold base 1, a mold inner shell 3, a mold bottom shell 4, a track plate 5, a linkage block 6, a linkage rod 7 and a cross bar 8. The top of the mold base 1 is fixedly connected with the mold shell 2; the top surface of the mold base 1 is provided with an avoidance groove 101, and the inner diameter of the avoidance groove 101 is smaller than the outer diameter of the mold inner shell 3. This design makes the device There will be no material leakage when steel parts are used; the mold inner shell 3 is fixedly connected to the top surface of the mold base 1, and the mold inner shell 3 is located inside the mold shell 2; the mold bottom shell 4 is plugged into the mold shell 2; The top surface of the mold bottom shell 4 is provided with a track stopper 401, and there are three track stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com